- Home

- Tools

- Power Tools

- Power Saws Blades

- Power Saw Blades

.....Read More

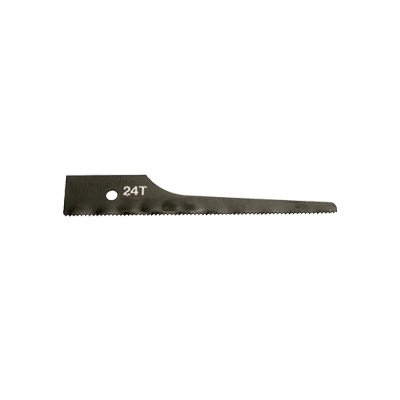

Air-Powered Reciprocating Saw Blades

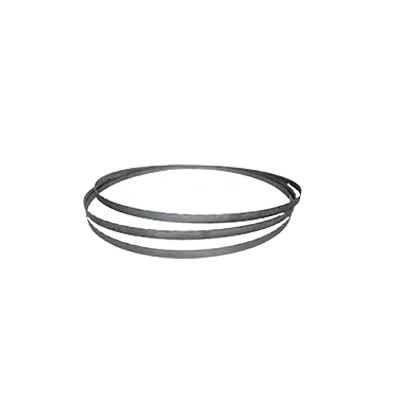

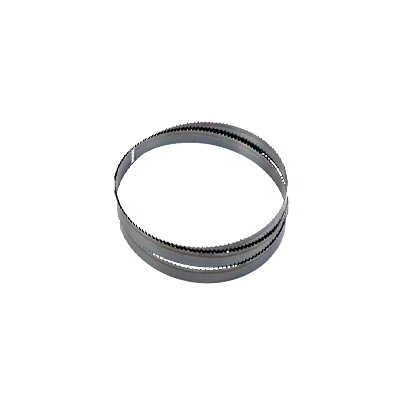

Band Saw Blade Coil Stock

Band Saw Blade Welders

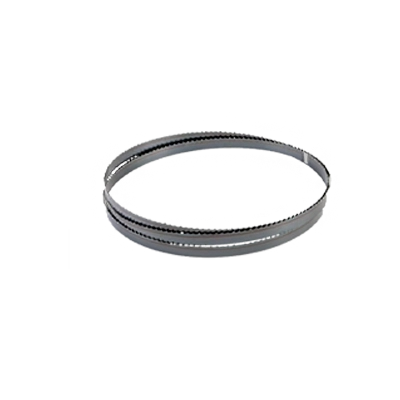

Blades for Portable Band Saws

Ceramic, Composites & Cast Iron Cutting Welded Band Saw Blades

Circular Saw Blades

Cold Saw Blades

Concrete Chain Saw Chains & Bars

Corded & Cordless Reciprocating Saw Blades

Dado Sets

Diamond Saw Blades

Drywall-Cutting Hole Saws

Food-Cutting Skinner Blades

Food-Cutting Welded Band Saw Blades

Hole Saw Arbors & Pilot Drill Bits

Hole Saw & Hole Cutter Cases & Chip Collectors

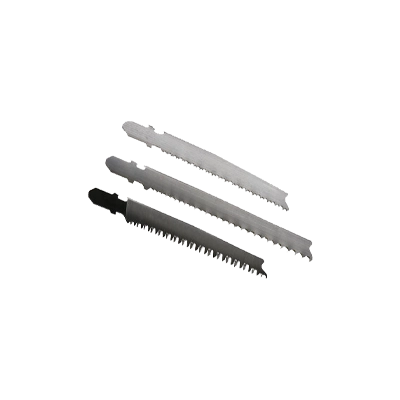

Jigsaw Blades

Jigsaw Blade Sets

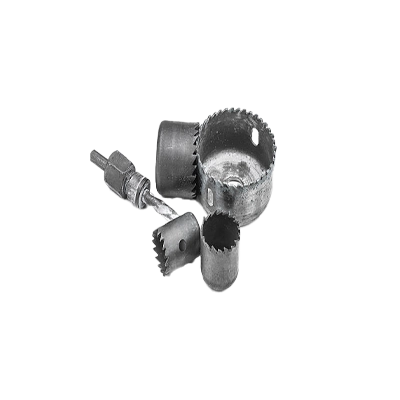

Masonry & Tile-Cutting Hole Saw Kits

Masonry & Tile-Cutting Hole Saws

Metal-Cutting Hole Cutter Kits

Metal-Cutting Hole Cutters

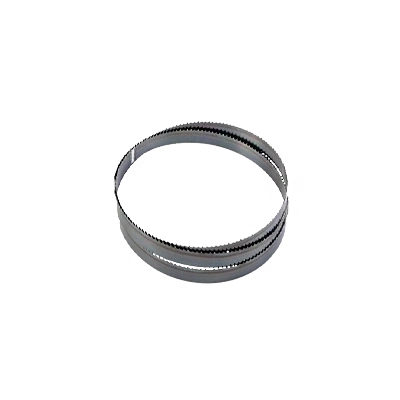

Metal-Cutting Welded Band Saw Blades

Multi-Material-Cutting Hole Saw Kits

Multi-Material-Cutting Hole Saws

Power Hacksaw Blades

Reciprocating Saw Blade Sets

Rough-In Hole Saw Kits for Wood

Rough-In Hole Saws for Wood

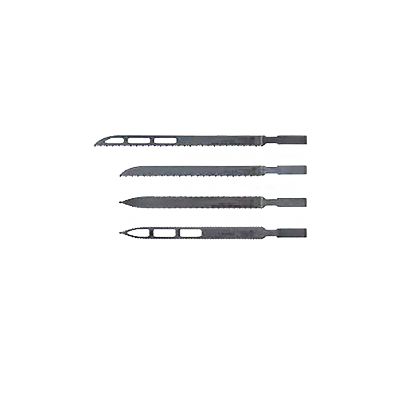

Scroll Saw Blades

Wood-Cutting Welded Band Saw Blades

Frequently Asked Questions

What are the different types of power saw blades and their uses?

How do I choose the right saw blade for my project?

What is the difference between a circular saw blade and a reciprocating saw blade?

How often should I replace my power saw blade?

What materials can diamond blades cut?

How do I maintain and clean my saw blades?

What are the safety precautions when using power saw blades?