- Home

- Tools

- Power Tools

- Power Saws Blades

- Masonry Saws Tile Saws Concrete Saws

.....Read More

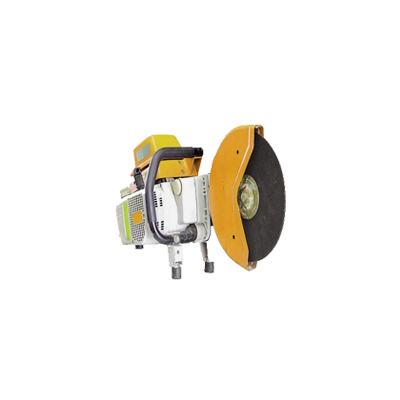

Corded Handheld Concrete Saws

Corded Tile Saws

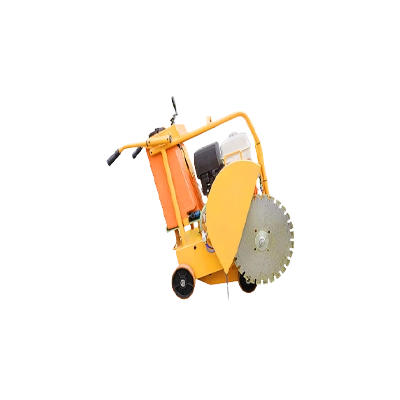

Corded Walk-Behind Concrete Saws

Cordless Handheld Concrete Saws

Cordless Walk-Behind Concrete Saws

Flooring Saws

Gas-Powered Concrete Chain Saws

Gas-Powered Handheld Concrete Saws

Gas-Powered Walk-Behind Concrete Saws

Handheld Concrete Saw Accessories

Masonry Saws

Replacement Parts for Masonry, Tile & Concrete Saws

Tile Saw Accessories

Frequently Asked Questions

What is the difference between a masonry saw and a tile saw?

How do I choose the right diamond blade for cutting concrete?

What safety precautions should be taken when using a concrete saw?

How do I maintain and clean a masonry saw?

Can a tile saw be used to cut other materials like stone or brick?

What is the best way to cut reinforced concrete?

How do I troubleshoot common issues with a walk-behind concrete saw?