- Home

- Tools

- Power Tools

- Power Saws Blades

- Band Saws

.....Read More

Automatic Horizontal Metal-Cutting Band Saws

Band Saw Accessories

Combination Metal- & Wood-Cutting Band Saws

Combination Vertical/Horizontal Metal-Cutting Band Saws

Corded Portable Band Saws

Cordless Portable Band Saws

Manual Horizontal Metal-Cutting Band Saws

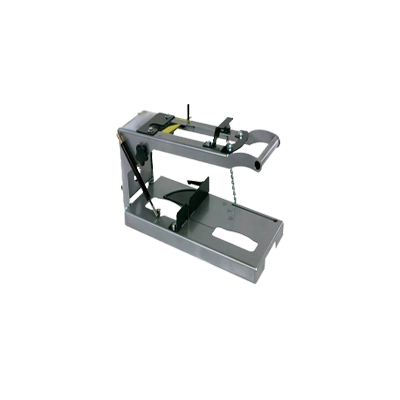

Portable Band Saw Accessories

Replacement Parts for Band Saws

Semi-Automatic Horizontal Metal-Cutting Band Saws

Vertical Metal-Cutting Band Saws

Wood-Cutting Band Saws

Frequently Asked Questions

What is a band saw used for?

How do you change a band saw blade?

What are the differences between a portable and stationary band saw?

How do you maintain a band saw?

What materials can a band saw cut?

How do you make straight cuts with a band saw?

What safety precautions should be taken when using a band saw?