Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Tools

- Power Tools

- Electrician S Power Tools

- Powered Cable Pullers Fishing Systems

.....Read More

Frequently Asked Questions

What are the benefits of using powered cable pullers over manual pullers?

Powered cable pullers offer several advantages over manual pullers:

1. **Increased Efficiency**: Powered cable pullers significantly reduce the time and effort required to pull cables, allowing for faster completion of projects. This efficiency is particularly beneficial in large-scale operations where long distances or heavy cables are involved.

2. **Enhanced Safety**: These machines minimize the physical strain on workers, reducing the risk of injuries associated with manual pulling, such as muscle strains or repetitive motion injuries. They also provide better control and stability, decreasing the likelihood of accidents.

3. **Consistent Performance**: Powered pullers deliver consistent pulling force, ensuring uniform tension throughout the process. This consistency helps prevent cable damage and ensures a smoother installation.

4. **Higher Capacity**: They can handle heavier loads and longer distances than manual pullers, making them suitable for more demanding tasks. This capability is crucial in industrial settings where large cables are common.

5. **Versatility**: Many powered pullers come with adjustable settings and interchangeable components, allowing them to be used for various cable types and sizes. This adaptability makes them a versatile tool for different projects.

6. **Labor Savings**: By reducing the need for manual labor, powered pullers can lower labor costs and free up workers for other tasks, improving overall productivity.

7. **Precision and Control**: Advanced models offer precise control over speed and tension, allowing for more accurate installations and reducing the risk of cable damage.

8. **Reduced Fatigue**: Operators experience less fatigue, leading to improved focus and efficiency, which can enhance the quality of work and reduce errors.

Overall, powered cable pullers provide a more efficient, safe, and versatile solution for cable installation compared to manual methods.

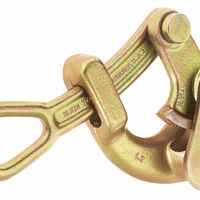

How do cable pulling jaw grips work?

Cable pulling jaw grips work by securely holding and pulling cables through conduits, ducts, or other pathways during installation. These tools are essential for ensuring that cables are installed without damage and with minimal effort.

The jaw grips are typically made of high-strength materials like steel to withstand the tension and force required during the pulling process. They consist of a set of jaws that open and close around the cable. The gripping mechanism is often designed with serrated or textured surfaces to increase friction and prevent slippage.

To use a cable pulling jaw grip, the operator opens the jaws and places the cable between them. Once the cable is positioned, the jaws are closed tightly around it. This is usually achieved through a locking mechanism or a tensioning device that ensures the grip remains secure during the pull. The design allows for even distribution of pressure along the cable, minimizing the risk of damage.

The other end of the jaw grip is typically attached to a pulling rope or wire, which is then connected to a winch or manual pulling device. As the pulling force is applied, the jaw grip holds the cable firmly, allowing it to be guided through the desired path.

Cable pulling jaw grips are versatile and can accommodate various cable sizes and types. They are crucial in electrical, telecommunications, and construction industries, where efficient and safe cable installation is necessary.

What is the difference between cable pulling rope and sheaves?

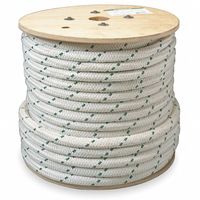

Cable pulling rope and sheaves are both used in the process of installing cables, but they serve different functions.

Cable pulling rope is a specialized rope designed to pull cables through conduits, ducts, or trays. It is typically made from materials like nylon, polyester, or polypropylene, which provide high tensile strength, flexibility, and resistance to abrasion. The rope is used to physically pull the cable along the desired path, often with the help of a winch or manual labor. It is essential for ensuring that the cable is installed without damage and with minimal friction.

Sheaves, on the other hand, are pulley-like devices used to guide and change the direction of the cable pulling rope or the cable itself. They consist of a wheel with a grooved rim that the rope or cable runs through. Sheaves are mounted on axles and can be fixed or swivel to accommodate different angles. They are crucial for reducing friction and wear on the cable and rope, especially when navigating bends or changes in elevation. By using sheaves, the pulling force required is minimized, and the risk of damaging the cable is reduced.

In summary, the cable pulling rope is the tool used to exert force and move the cable, while sheaves are components that facilitate the movement by guiding and reducing friction. Both are essential for efficient and safe cable installation.

How do cordless fish tapes improve the cable pulling process?

Cordless fish tapes enhance the cable pulling process by offering increased efficiency, safety, and convenience. Traditional fish tapes require manual effort to extend and retract, which can be time-consuming and physically demanding. Cordless fish tapes, powered by batteries, automate these tasks, significantly reducing the physical strain on workers and speeding up the process.

The motorized operation of cordless fish tapes allows for smoother and more consistent extension and retraction of the tape, minimizing the risk of kinks and tangles that can occur with manual tapes. This results in less downtime spent on untangling and more time focused on the actual task of pulling cables.

Cordless fish tapes also improve safety by reducing the need for excessive force, which can lead to injuries. The automated mechanism ensures a controlled and steady pull, decreasing the likelihood of sudden jerks that could cause harm to the user or damage to the cables and conduits.

Furthermore, the portability of cordless fish tapes, due to their battery-powered nature, allows for greater flexibility and ease of use in various environments, including tight spaces and areas without easy access to power outlets. This makes them particularly useful in large-scale or complex installations where mobility is crucial.

Overall, cordless fish tapes streamline the cable pulling process by combining automation with portability, leading to faster, safer, and more efficient operations.

What are vacuum and blower fishing systems, and how do they work?

Vacuum and blower fishing systems are specialized equipment used in the aquaculture and fishing industries to efficiently transfer fish from one location to another, such as from a pond to a transport vehicle or processing facility.

**Vacuum Fishing Systems:**

These systems use a vacuum pump to create a suction force that draws fish through a hose or pipe. The process begins with submerging the intake end of the hose into the water where the fish are located. The vacuum pump generates a pressure differential, causing water and fish to be sucked into the hose. The fish are then transported through the hose to a holding tank or container. The system is designed to minimize stress and physical damage to the fish, making it suitable for live fish transfer. Vacuum systems are often used in aquaculture for harvesting fish from tanks or ponds.

**Blower Fishing Systems:**

Blower systems, on the other hand, use a blower or air pump to create a flow of air that pushes fish through a pipe. The system typically involves a blower connected to a pipe with an intake submerged in the water. The blower forces air into the pipe, creating a flow that propels fish along with the water through the pipe to the desired location. Blower systems are generally used for moving smaller fish or fry and are less common than vacuum systems due to the potential for increased stress and injury to the fish.

Both systems aim to improve efficiency and reduce labor costs in fish handling operations while ensuring the welfare of the fish during transfer. They are particularly useful in large-scale aquaculture operations where manual handling would be impractical.

How do you choose the right cable puller for a specific job?

To choose the right cable puller for a specific job, consider the following factors:

1. **Load Capacity**: Determine the weight and tension requirements of the cables you need to pull. Choose a cable puller with a load capacity that exceeds the maximum expected load to ensure safety and efficiency.

2. **Cable Type and Size**: Identify the type and diameter of the cable. Some pullers are designed for specific cable types, such as fiber optic or electrical cables, and may have limitations on the size they can handle.

3. **Distance and Environment**: Consider the length of the cable run and the environment in which you are working. For long distances or challenging terrains, a powered cable puller might be more suitable than a manual one.

4. **Power Source**: Decide between manual, electric, hydraulic, or battery-operated pullers based on the availability of power sources and the nature of the job site. Electric and hydraulic pullers are ideal for heavy-duty tasks, while manual pullers are suitable for lighter loads.

5. **Portability and Ease of Use**: Evaluate the weight and portability of the puller, especially if the job requires frequent relocation. Look for features like ergonomic handles and easy setup to enhance usability.

6. **Safety Features**: Ensure the puller has safety features such as overload protection, automatic shut-off, and secure anchoring systems to prevent accidents.

7. **Budget and Brand**: Consider your budget and opt for reputable brands known for durability and reliability. Investing in a high-quality puller can reduce maintenance costs and downtime.

8. **Job Frequency**: For frequent use, invest in a durable, high-performance puller. For occasional tasks, a more economical option may suffice.

By assessing these factors, you can select a cable puller that meets the specific demands of your job, ensuring efficiency and safety.

What safety precautions should be taken when using powered cable pullers?

1. **Training and Certification**: Ensure operators are properly trained and certified to use powered cable pullers.

2. **Inspection**: Conduct a thorough inspection of the equipment before use, checking for any signs of wear, damage, or malfunction.

3. **Personal Protective Equipment (PPE)**: Wear appropriate PPE, including gloves, safety glasses, hard hats, and steel-toed boots.

4. **Load Limits**: Adhere to the manufacturer's specified load limits to prevent overloading the equipment.

5. **Secure Setup**: Ensure the puller is securely anchored and stable before operation. Use appropriate rigging and anchoring techniques.

6. **Clear Area**: Keep the work area clear of unnecessary personnel and obstacles. Establish a safe perimeter around the operation zone.

7. **Communication**: Maintain clear communication among team members, using hand signals or radios if necessary.

8. **Emergency Procedures**: Be familiar with emergency shutdown procedures and have a plan in place for potential accidents.

9. **Avoid Pinch Points**: Be aware of and avoid pinch points and moving parts to prevent injuries.

10. **Proper Alignment**: Ensure the cable is properly aligned with the puller to prevent twisting or kinking.

11. **Tension Monitoring**: Continuously monitor cable tension to avoid sudden releases or snapping.

12. **Weather Conditions**: Consider weather conditions, as rain or ice can affect equipment performance and safety.

13. **Regular Maintenance**: Follow a regular maintenance schedule to keep the equipment in optimal working condition.

14. **Documentation**: Keep records of inspections, maintenance, and any incidents for future reference and compliance.

15. **Manufacturer Guidelines**: Always follow the manufacturer's guidelines and instructions for safe operation.