- Home

- Tools

- Power Tools

- Electrician S Power Tools

- Cable Cutting Stripping Crimping Power Tools

.....Read More

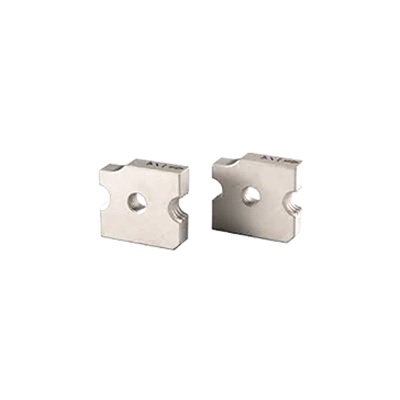

Cable Stripper Bushings

Cordless Bolt, Threaded Rod & Cable Tray Cutters

Cordless Cable Cutters

Cordless Cable Tie Tools

Cordless Crimpers

Cordless Wire & Cable Strippers

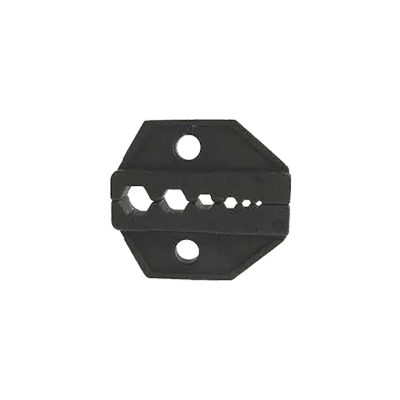

Jaws & Cutting Dies for Cordless Crimpers

Power Hydraulic Wire & Cable Cutters

Replacement Blades for Cordless Bolt, Threaded Rod & Cable Tray Cutters

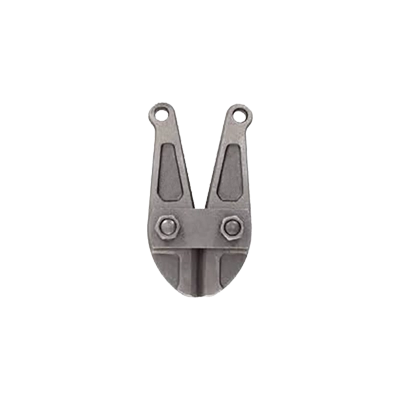

Replacement Jaws & Blades for Cable Cutters

Twist-On Wire Connector Drill Attachments

Frequently Asked Questions

What are the best tools for cutting and stripping cables?

How do I choose the right crimping tool for my needs?

What is the difference between manual and automatic cable strippers?

How do I properly use a cable tie tool?

What safety precautions should I take when using cable cutting and crimping tools?

How do I maintain and care for my cable tools to ensure longevity?

Can I use the same tool for different types of cables and wires?