Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Test Instruments

- Force Testing

.....Read More

Frequently Asked Questions

What is force testing equipment?

Force testing equipment refers to devices and instruments used to measure the strength, durability, and performance of materials, components, or products by applying controlled forces. These tools are essential in quality control, research and development, and manufacturing processes across various industries, including automotive, aerospace, construction, and consumer goods.

The primary function of force testing equipment is to apply tension, compression, bending, shear, or torsion to a test specimen to evaluate its mechanical properties. The results help determine the material's behavior under different conditions, ensuring it meets specific standards and requirements.

Common types of force testing equipment include:

1. **Universal Testing Machines (UTMs):** These versatile machines can perform a wide range of tests, including tensile, compression, and flexural tests. They are equipped with load cells, grips, and fixtures to accommodate different specimen shapes and sizes.

2. **Tensile Testers:** Specifically designed to measure the tensile strength of materials, these machines pull a specimen until it breaks, recording the force and elongation.

3. **Compression Testers:** These devices apply compressive forces to evaluate a material's ability to withstand crushing or buckling.

4. **Torque Testers:** Used to measure the rotational force or torque applied to an object, essential for testing fasteners, caps, and other components.

5. **Hardness Testers:** These instruments assess a material's resistance to deformation, often using methods like Rockwell, Brinell, or Vickers hardness tests.

Force testing equipment is crucial for ensuring product safety, reliability, and compliance with industry standards. By providing precise and repeatable measurements, these tools help manufacturers optimize designs, improve material selection, and enhance overall product quality.

How does a force gauge work?

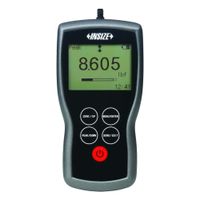

A force gauge is a measuring instrument used to quantify the magnitude of force applied to an object. It operates based on either mechanical or digital principles.

Mechanical force gauges typically use a spring mechanism. When a force is applied, it compresses or stretches a calibrated spring. The displacement of the spring is proportional to the force applied, and this displacement is displayed on a dial or scale. The gauge is calibrated to convert the spring's displacement into a force measurement, usually in units like newtons or pounds.

Digital force gauges, on the other hand, use a load cell, which is a transducer that converts force into an electrical signal. The most common type of load cell is the strain gauge load cell. It consists of a metal body with strain gauges bonded to it. When force is applied, the metal body deforms slightly, causing a change in the electrical resistance of the strain gauges. This change is proportional to the force applied. The electrical signal is then amplified and processed by a microprocessor, which converts it into a digital readout displayed on the gauge's screen.

Both types of force gauges can measure tension (pulling force) and compression (pushing force). They are used in various applications, including quality control, research and development, and manufacturing processes, to ensure that products meet specified force requirements. Calibration is essential for maintaining accuracy, and force gauges should be regularly checked against known standards to ensure reliable measurements.

What are the types of force testing equipment?

Force testing equipment is essential for evaluating the mechanical properties of materials and components. The primary types include:

1. **Universal Testing Machines (UTMs):** These versatile machines perform tensile, compression, and bending tests. They are equipped with interchangeable fixtures and grips to accommodate various materials and test types.

2. **Tensile Testers:** Specifically designed to measure the tensile strength of materials, these machines apply a uniaxial force to a specimen until it breaks, providing data on elongation, yield strength, and ultimate tensile strength.

3. **Compression Testers:** These machines evaluate the compressive strength of materials by applying a force that compresses the specimen. They are crucial for testing materials like concrete, metals, and polymers.

4. **Torque Testers:** Used to measure the torque or rotational force applied to an object. They are essential in testing fasteners, caps, and other components requiring rotational force.

5. **Peel Testers:** These machines assess the adhesive strength of materials by measuring the force required to peel a material from a substrate. They are commonly used in packaging and adhesive industries.

6. **Shear Testers:** Designed to measure the shear strength of materials, these testers apply a force parallel to the surface of the specimen, often used in testing adhesives and layered materials.

7. **Impact Testers:** These machines evaluate a material's ability to withstand sudden forces or shocks. Common types include Charpy and Izod impact testers, which measure the energy absorbed by a material during fracture.

8. **Hardness Testers:** While not directly measuring force, these devices assess a material's resistance to deformation. Common methods include Rockwell, Brinell, and Vickers hardness tests.

Each type of force testing equipment is tailored to specific applications, ensuring accurate and reliable measurement of material properties.

How do you calibrate a force gauge?

To calibrate a force gauge, follow these steps:

1. **Preparation**: Ensure the force gauge is clean and free from any damage. Gather necessary equipment, including calibration weights or a certified calibration device, and a stable test stand.

2. **Zeroing**: Turn on the force gauge and allow it to warm up if required. Zero the gauge by pressing the tare or zero button to ensure it reads zero with no load applied.

3. **Select Units**: Set the force gauge to the desired measurement units (e.g., Newtons, pounds).

4. **Calibration Setup**: Secure the force gauge to a stable test stand to prevent movement during calibration. Ensure the setup is vertical to avoid measurement errors.

5. **Apply Known Weights**: Gradually apply known calibration weights to the force gauge. Start with the smallest weight and increase incrementally. Ensure weights are applied smoothly and steadily to avoid dynamic forces.

6. **Record Readings**: For each weight applied, record the reading displayed on the force gauge. Compare these readings to the known values of the calibration weights.

7. **Adjust Calibration**: If the readings deviate from the known values, adjust the calibration settings on the force gauge according to the manufacturer's instructions. This may involve entering a calibration mode and adjusting the span or gain settings.

8. **Repeat and Verify**: Repeat the process to verify the accuracy of the calibration. Ensure the force gauge consistently reads accurately across the range of weights.

9. **Documentation**: Document the calibration process, including the date, equipment used, and results. Maintain records for quality assurance and compliance purposes.

10. **Regular Calibration**: Schedule regular calibration intervals based on usage frequency and manufacturer recommendations to ensure ongoing accuracy.

What industries use force testing equipment?

Force testing equipment is utilized across a wide range of industries to ensure product quality, safety, and compliance with standards. Key industries include:

1. **Automotive Industry**: Used for testing the strength and durability of components like seat belts, airbags, and suspension systems to ensure safety and performance.

2. **Aerospace Industry**: Essential for testing materials and components such as wings, fuselage, and landing gear to withstand extreme conditions and stresses.

3. **Manufacturing**: Employed in quality control processes to test the tensile, compressive, and shear strength of materials and products, ensuring they meet specifications.

4. **Construction**: Used to test the strength and load-bearing capacity of building materials like concrete, steel, and wood to ensure structural integrity.

5. **Electronics**: Utilized for testing the durability and reliability of electronic components and assemblies, including connectors and circuit boards.

6. **Medical Devices**: Critical for testing the strength and functionality of medical devices and equipment, such as surgical instruments and prosthetics, to ensure patient safety.

7. **Textile Industry**: Used to test the tensile strength, elasticity, and durability of fabrics and fibers, ensuring they meet quality standards.

8. **Consumer Goods**: Employed to test the durability and safety of products like toys, furniture, and appliances to ensure they are safe for consumer use.

9. **Packaging**: Used to test the strength and durability of packaging materials to ensure they can protect contents during shipping and handling.

10. **Food and Beverage**: Utilized to test the strength and integrity of packaging and containers to ensure product safety and quality.

These industries rely on force testing equipment to maintain high standards of quality, safety, and performance in their products and materials.

What is the difference between a digital and mechanical force gauge?

A digital force gauge and a mechanical force gauge are both instruments used to measure force, but they differ in design, functionality, and features.

A digital force gauge uses electronic components to measure force and display the results on a digital screen. It typically consists of a load cell, which converts the force into an electrical signal, and a microprocessor that processes this signal to provide a digital readout. Digital force gauges offer high precision and accuracy, often with the ability to measure in various units (e.g., Newtons, pounds, kilograms). They can store data, connect to computers for analysis, and offer features like peak hold, averaging, and programmable limits. They are user-friendly, with easy-to-read displays and often come with software for data management.

In contrast, a mechanical force gauge operates on a purely mechanical principle, usually involving a spring or a hydraulic system. When force is applied, it causes a deflection or compression in the spring, which is then translated into a force measurement displayed on a dial or scale. Mechanical force gauges are simple, durable, and do not require a power source, making them suitable for rugged environments. However, they generally offer less precision and fewer features compared to digital gauges. They are limited to the units of measurement marked on the dial and do not provide data storage or connectivity options.

In summary, digital force gauges are more advanced, offering precision, versatility, and additional features, while mechanical force gauges are simpler, more robust, and suitable for basic applications where high precision is not critical.

How do you choose the right force testing equipment?

Choosing the right force testing equipment involves several key considerations to ensure accuracy, efficiency, and suitability for your specific application. First, identify the type of force measurement needed, such as tension, compression, or torque, and the range of forces you expect to measure. This helps in selecting equipment with the appropriate load capacity and sensitivity.

Next, consider the material and specimen size you will be testing. This determines the type of grips or fixtures required to hold the specimen securely during testing. Ensure the equipment can accommodate the dimensions and characteristics of your samples.

Accuracy and precision are critical, so evaluate the equipment's resolution and calibration capabilities. Look for machines with high precision load cells and those that comply with relevant industry standards, such as ASTM or ISO, to ensure reliable results.

Consider the software and data analysis capabilities of the equipment. Advanced software can provide detailed insights, automate testing processes, and facilitate easy data export and reporting. Ensure the interface is user-friendly and compatible with your existing systems.

Evaluate the equipment's versatility and adaptability. Some machines offer modular designs that allow for future upgrades or the addition of new testing capabilities, which can be cost-effective in the long run.

Assess the manufacturer’s reputation, customer support, and service options. Reliable technical support and readily available spare parts can minimize downtime and ensure smooth operation.

Finally, consider your budget and total cost of ownership, including initial purchase price, maintenance, and potential upgrades. Balancing cost with the required features and quality is crucial for making a sound investment in force testing equipment.

What are common applications of force testing equipment?

Force testing equipment is widely used across various industries to measure the strength, durability, and performance of materials and products. Here are some common applications:

1. **Quality Control**: In manufacturing, force testing ensures products meet specified standards and regulations. It helps in verifying the strength and durability of materials, ensuring they can withstand expected loads and stresses.

2. **Material Testing**: Used to determine the mechanical properties of materials such as tensile strength, compressive strength, and elasticity. This is crucial in industries like construction, aerospace, and automotive, where material performance is critical.

3. **Product Development**: During the design phase, force testing helps in evaluating prototypes to ensure they meet design specifications and performance criteria. It aids in identifying potential weaknesses and improving product design.

4. **Safety Testing**: Ensures that products can withstand forces they might encounter during use, reducing the risk of failure and ensuring user safety. This is particularly important in consumer goods, medical devices, and automotive components.

5. **Research and Development**: In R&D, force testing is used to explore new materials and technologies, providing data on how materials behave under different forces and conditions.

6. **Compliance Testing**: Many industries have regulatory requirements that products must meet. Force testing helps in demonstrating compliance with these standards, such as ASTM, ISO, and other industry-specific regulations.

7. **Failure Analysis**: When products fail, force testing can help determine the cause by simulating the conditions that led to the failure, providing insights for corrective actions.

8. **Packaging Testing**: Ensures that packaging materials can protect their contents during transportation and handling by testing their resistance to compression, tension, and other forces.

These applications highlight the versatility and importance of force testing equipment in ensuring product quality, safety, and performance across various sectors.

How often should force testing equipment be calibrated?

Force testing equipment should be calibrated at least once a year to ensure accuracy and reliability. However, the frequency can vary based on several factors:

1. **Manufacturer's Recommendations**: Always follow the manufacturer's guidelines for calibration frequency, as they are tailored to the specific equipment.

2. **Usage Frequency**: Equipment used frequently or in critical applications may require more frequent calibration, such as every six months or quarterly.

3. **Environmental Conditions**: Harsh environments, such as those with extreme temperatures, humidity, or vibration, can affect equipment performance, necessitating more frequent calibration.

4. **Regulatory Requirements**: Industries with strict regulatory standards, such as aerospace, automotive, or pharmaceuticals, may have specific calibration intervals mandated by governing bodies.

5. **Quality Assurance Policies**: Organizations with robust quality management systems may have internal policies dictating calibration schedules to maintain compliance with standards like ISO 9001.

6. **Historical Performance**: If past calibrations have shown significant drift or errors, increasing the frequency may be necessary to maintain accuracy.

7. **Criticality of Measurements**: For applications where precision is crucial, more frequent calibration ensures that measurements remain within acceptable tolerances.

8. **Post-Repair or Adjustment**: Calibration should be performed after any repairs or adjustments to the equipment to verify its accuracy.

9. **Initial Calibration**: New equipment should be calibrated upon installation to establish a baseline for future calibrations.

Ultimately, the calibration schedule should be determined by a risk-based approach, considering the factors above to ensure the equipment consistently provides accurate and reliable measurements.

What accessories are needed for force testing equipment?

Force testing equipment requires several accessories to ensure accurate and efficient testing. These include:

1. **Load Cells**: Essential for measuring the force applied during testing. They come in various capacities and types to suit different testing requirements.

2. **Grips and Fixtures**: Used to hold the test specimen securely. Different types are available, such as wedge grips, pneumatic grips, and specialized fixtures for specific materials or shapes.

3. **Extensometers**: Measure the deformation or elongation of the specimen. They are crucial for tests that require precise strain measurements.

4. **Compression Platens**: Used for compression testing, these platens apply force evenly across the specimen.

5. **Software**: Advanced software is necessary for data acquisition, analysis, and reporting. It helps in controlling the testing machine and processing the results.

6. **Environmental Chambers**: Allow testing under controlled temperature and humidity conditions, which is essential for materials sensitive to environmental changes.

7. **Adapters and Couplings**: Facilitate the connection between different components of the testing system, ensuring compatibility and flexibility.

8. **Safety Shields and Guards**: Protect operators from potential hazards during testing, especially in high-force applications.

9. **Calibration Tools**: Ensure the accuracy and reliability of the testing equipment by regularly calibrating load cells and other sensors.

10. **Data Acquisition Systems**: Capture and record test data for analysis. They often integrate with the testing software for seamless operation.

11. **Alignment Tools**: Ensure that the test specimen is properly aligned to avoid errors in force application and measurement.

These accessories enhance the functionality and versatility of force testing equipment, enabling precise and reliable testing across various applications.