Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

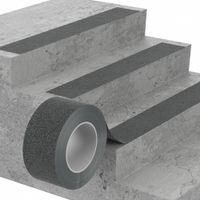

What are antislip tapes and how do they work?

Antislip tapes are adhesive strips or rolls designed to enhance traction on surfaces, thereby reducing the risk of slips and falls. They are commonly used in areas prone to moisture or where foot traffic is heavy, such as stairs, ramps, walkways, and industrial floors.

These tapes are typically made from durable materials like PVC, PET, or aluminum oxide, which are embedded with abrasive particles. The abrasive surface provides the necessary friction to prevent slipping. The backing of the tape is coated with a strong adhesive that ensures it remains securely attached to the surface, even under heavy use or in wet conditions.

Antislip tapes work by increasing the coefficient of friction between the foot and the surface. When a person steps on the tape, the rough texture grips the sole of the shoe, reducing the likelihood of slipping. This is particularly effective in environments where water, oil, or other slippery substances may be present.

Installation is straightforward: the surface must be clean and dry before application. The tape is then cut to the desired length, peeled from its backing, and pressed firmly onto the surface. Some tapes are designed for specific environments, such as glow-in-the-dark tapes for low-light areas or chemical-resistant tapes for industrial settings.

Overall, antislip tapes are a cost-effective and versatile solution for enhancing safety in various settings, providing peace of mind and reducing the risk of accidents.

How do I install antislip stair treads and nosings?

1. **Preparation**: Clean the stairs thoroughly to remove dirt, dust, and grease. Ensure the surface is dry and smooth. Repair any damage or uneven areas on the stairs.

2. **Measurement and Cutting**: Measure the width and depth of each stair. Cut the anti-slip treads and nosings to fit these dimensions using a utility knife or a saw, depending on the material.

3. **Positioning**: Place the treads and nosings on the stairs to check the fit. Ensure they are centered and aligned properly. Mark their positions with a pencil.

4. **Adhesive Application**: For adhesive-backed treads, peel off the backing and press them firmly onto the stairs. For non-adhesive treads, apply a suitable adhesive (like construction adhesive) to the back of the treads and nosings. Follow the manufacturer's instructions for the adhesive.

5. **Installation**: Press the treads and nosings firmly onto the stairs, starting from one end and working to the other to avoid air bubbles. Use a roller or a flat tool to ensure even adhesion.

6. **Securing**: For additional security, use screws or nails to fasten the treads and nosings. Drill pilot holes to prevent splitting, and countersink the screws for a flush finish.

7. **Curing**: Allow the adhesive to cure as per the manufacturer's instructions before using the stairs. This usually takes 24-48 hours.

8. **Final Check**: Inspect the installation to ensure all treads and nosings are secure and properly aligned. Make any necessary adjustments.

9. **Maintenance**: Regularly clean the treads and nosings to maintain their anti-slip properties and check for any signs of wear or loosening.

What materials are antislip stair treads and nosings made from?

Antislip stair treads and nosings are designed to enhance safety by providing traction and reducing the risk of slips and falls. They are made from a variety of materials, each offering distinct advantages:

1. **Rubber**: Rubber treads are popular for their durability, flexibility, and excellent slip resistance. They are often used in indoor environments and are available in various textures and colors.

2. **Aluminum**: Aluminum treads and nosings are lightweight, corrosion-resistant, and suitable for both indoor and outdoor use. They often feature abrasive inserts or coatings to enhance grip.

3. **Vinyl**: Vinyl treads are cost-effective and easy to install. They are commonly used in residential and light commercial settings and come in a range of colors and patterns.

4. **Fiberglass**: Fiberglass treads are known for their strength and resistance to chemicals and moisture. They are ideal for industrial environments and can be embedded with grit for added traction.

5. **Carborundum**: This material is used in high-traffic areas and involves embedding silicon carbide granules into metal or other substrates to create a highly abrasive surface.

6. **Wood**: Treated wood treads can be used in outdoor settings. They are often grooved or textured to improve slip resistance.

7. **Concrete**: Concrete treads can be treated with anti-slip coatings or embedded with abrasive materials to enhance traction.

8. **Stainless Steel**: Stainless steel treads are durable and resistant to corrosion, making them suitable for harsh environments. They often have a textured finish for improved grip.

9. **Composite Materials**: These combine various materials to offer enhanced durability and slip resistance, often used in heavy-duty applications.

Each material is chosen based on the specific requirements of the environment, such as exposure to weather, foot traffic, and aesthetic preferences.

How do I choose the right antislip product for my stairs?

To choose the right antislip product for your stairs, consider the following factors:

1. **Material Compatibility**: Identify the material of your stairs (wood, concrete, metal, etc.) and select a product designed for that specific surface to ensure proper adhesion and effectiveness.

2. **Indoor vs. Outdoor Use**: Determine whether your stairs are indoors or outdoors. Outdoor stairs require products that can withstand weather conditions, such as rain, snow, and UV exposure.

3. **Level of Traffic**: Assess the amount of foot traffic your stairs receive. High-traffic areas may need more durable solutions like heavy-duty tapes or coatings.

4. **Aesthetic Preferences**: Consider the visual impact. Transparent tapes or coatings preserve the natural look of the stairs, while colored or textured options can enhance visibility and safety.

5. **Ease of Installation**: Evaluate your DIY skills and the complexity of installation. Some products, like adhesive tapes, are easy to apply, while others, like coatings, may require professional application.

6. **Maintenance Requirements**: Choose a product that aligns with your maintenance capabilities. Some antislip solutions require regular cleaning or reapplication to maintain effectiveness.

7. **Safety Standards**: Ensure the product meets relevant safety standards and certifications for slip resistance to guarantee effectiveness.

8. **Budget**: Balance cost with quality. While cheaper options may be tempting, investing in a durable, high-quality product can save money in the long run by reducing the need for frequent replacements.

9. **Reviews and Recommendations**: Research customer reviews and seek recommendations from professionals or friends who have used antislip products successfully.

By considering these factors, you can select an antislip product that effectively enhances the safety and functionality of your stairs.

Are antislip stair treads and nosings suitable for outdoor use?

Yes, anti-slip stair treads and nosings are suitable for outdoor use. These products are specifically designed to enhance safety by providing additional traction on staircases, which is crucial in outdoor environments where stairs are often exposed to elements like rain, snow, and ice.

Outdoor anti-slip treads and nosings are typically made from durable materials such as aluminum, fiberglass, or rubber, which are resistant to weathering and corrosion. These materials ensure longevity and maintain their anti-slip properties even under harsh conditions. Some treads and nosings also feature embedded grit or abrasive surfaces that enhance grip, reducing the risk of slips and falls.

Additionally, these products are available in various designs and finishes to complement different architectural styles, making them both functional and aesthetically pleasing. They can be installed on a variety of surfaces, including wood, concrete, and metal, providing versatility for different outdoor settings.

Installation is generally straightforward, with options for adhesive or mechanical fastening, ensuring they remain securely in place. Many products also meet safety standards and regulations, providing peace of mind regarding compliance with building codes.

In summary, anti-slip stair treads and nosings are highly suitable for outdoor use due to their durability, effectiveness in preventing slips, and adaptability to different environments and surfaces.

How long do antislip tapes and stair treads last?

The longevity of anti-slip tapes and stair treads depends on several factors, including the quality of the product, the environment in which they are used, and the level of foot traffic they experience.

1. **Quality of Material**: High-quality anti-slip tapes and stair treads made from durable materials like aluminum oxide or rubber tend to last longer. These materials are designed to withstand wear and tear, providing a longer lifespan compared to cheaper alternatives.

2. **Environmental Conditions**: In outdoor settings, exposure to elements such as rain, snow, UV rays, and temperature fluctuations can affect the durability of anti-slip products. Products specifically designed for outdoor use typically have UV-resistant and weatherproof properties, extending their lifespan.

3. **Foot Traffic**: Areas with high foot traffic will see faster wear on anti-slip tapes and stair treads. In commercial or industrial settings, where usage is frequent and heavy, these products may need replacement more often compared to residential settings.

4. **Installation and Maintenance**: Proper installation is crucial for maximizing the lifespan of anti-slip products. Ensuring a clean, dry surface before application can prevent premature peeling or detachment. Regular maintenance, such as cleaning to remove dirt and debris, can also prolong their effectiveness.

On average, high-quality anti-slip tapes and stair treads can last anywhere from 1 to 5 years. In optimal conditions with moderate use, they may last even longer. However, in harsh environments or high-traffic areas, they might need replacement every 6 months to 2 years. Regular inspection is recommended to ensure they remain effective and safe.

Can antislip products be used on wooden stairs?

Yes, antislip products can be used on wooden stairs to enhance safety and prevent accidents. These products are designed to increase traction and reduce the risk of slipping, especially in areas prone to moisture or heavy foot traffic. There are several types of antislip solutions suitable for wooden stairs:

1. **Antislip Tapes**: These are adhesive strips with a gritty surface that can be easily applied to the edge of each step. They are available in various colors and transparencies to match the aesthetic of the stairs.

2. **Non-Slip Paints and Coatings**: These are specially formulated paints that contain abrasive materials to create a textured surface. They can be applied directly to the wood and are available in clear or colored options.

3. **Rubber or Vinyl Treads**: These are pre-cut strips or mats that can be affixed to each step. They provide a cushioned, non-slip surface and are often used in both residential and commercial settings.

4. **Grip Mats**: These are removable mats that can be placed on each step. They are easy to clean and replace, making them a convenient option for temporary use.

5. **Wood Treatments**: Some wood treatments and sealants include non-slip additives that can be applied during the finishing process to enhance grip without altering the appearance of the wood.

When selecting an antislip product, consider factors such as durability, ease of installation, maintenance, and aesthetic compatibility with the existing staircase design. Proper installation is crucial to ensure effectiveness and longevity. Regular maintenance, such as cleaning and checking for wear, will help maintain the antislip properties over time.

What are the benefits of using antislip stair nosings?

Antislip stair nosings offer several benefits that enhance safety, durability, and aesthetics. Primarily, they significantly reduce the risk of slips and falls on stairs, which is crucial in both residential and commercial settings. By providing additional grip, they ensure safer footing, especially in high-traffic areas or where stairs may become wet or greasy.

Durability is another key advantage. Stair nosings protect the edges of stairs from wear and tear, extending the lifespan of the stairway. This is particularly beneficial in environments with heavy foot traffic, where stairs are prone to damage. By reinforcing the stair edges, nosings help maintain the structural integrity of the stairs over time.

From an aesthetic perspective, antislip stair nosings can enhance the visual appeal of a staircase. Available in various materials, colors, and finishes, they can complement or contrast with the existing decor, adding a touch of style while serving a functional purpose. This can be particularly important in commercial spaces where brand image and customer impressions matter.

Additionally, stair nosings can aid in compliance with building regulations and safety standards, which often require measures to prevent accidents on stairs. By installing antislip nosings, property owners can ensure they meet these legal requirements, potentially avoiding liability issues.

In summary, antislip stair nosings provide enhanced safety, increased durability, aesthetic improvement, and regulatory compliance, making them a valuable addition to any staircase.

How do I maintain and clean antislip stair treads and nosings?

To maintain and clean antislip stair treads and nosings, follow these steps:

1. **Regular Inspection**: Frequently check for wear and tear, ensuring the antislip properties are intact. Look for any damage or loosening that might compromise safety.

2. **Sweeping and Dusting**: Regularly sweep the treads and nosings to remove dirt, dust, and debris. Use a soft-bristle broom or a vacuum cleaner with a brush attachment to avoid scratching the surface.

3. **Cleaning Solution**: Prepare a mild cleaning solution using warm water and a gentle detergent. Avoid harsh chemicals that can degrade the antislip surface.

4. **Mopping**: Use a damp mop or cloth to clean the surface. Ensure the mop is not too wet to prevent water from seeping into the material, which could cause damage.

5. **Stain Removal**: For stubborn stains, use a soft brush and the cleaning solution to gently scrub the area. Avoid abrasive pads that can scratch or wear down the antislip surface.

6. **Rinsing**: After cleaning, rinse the treads and nosings with clean water to remove any soap residue, which can make the surface slippery.

7. **Drying**: Thoroughly dry the area with a clean, dry cloth or allow it to air dry. Ensure no moisture is left, as it can lead to mold or mildew growth.

8. **Periodic Deep Cleaning**: Depending on foot traffic, perform a deep clean periodically using a specialized antislip cleaner. Follow the manufacturer's instructions for best results.

9. **Reapplication**: If the antislip properties diminish, consider reapplying an antislip coating or replacing the treads and nosings to maintain safety.

10. **Preventive Measures**: Place mats at entrances to reduce dirt and moisture transfer. Encourage users to wipe their feet before using the stairs.

By following these steps, you can ensure the longevity and effectiveness of your antislip stair treads and nosings.

Are there any regulations or standards for antislip stair products?

Yes, there are regulations and standards for antislip stair products to ensure safety and prevent accidents. These standards vary by country but generally focus on slip resistance, durability, and installation guidelines.

In the United States, the Occupational Safety and Health Administration (OSHA) provides regulations for stair safety, including slip resistance. The American National Standards Institute (ANSI) and the National Floor Safety Institute (NFSI) have developed standards such as ANSI/NFSI B101.1, which specifies the test method for measuring the wet static coefficient of friction of common hard-surface floor materials.

In Europe, the European Committee for Standardization (CEN) has established standards like EN 13552, which specifies requirements for antislip properties of floor coverings. The UK follows the Health and Safety Executive (HSE) guidelines, which recommend a pendulum test to measure slip resistance, with a minimum Pendulum Test Value (PTV) of 36 for safe surfaces.

Australia and New Zealand adhere to AS/NZS 4586, which outlines slip resistance classification of new pedestrian surface materials, and AS/NZS 4663 for existing surfaces.

These standards ensure that antislip stair products are tested for slip resistance under various conditions, including wet and dry environments. They also provide guidelines for the proper installation and maintenance of these products to maintain their effectiveness over time.

Manufacturers and suppliers of antislip stair products must comply with these standards to ensure their products are safe for use in public and private spaces. Compliance with these regulations helps reduce the risk of slips and falls, thereby enhancing safety for users.