Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Plastics

.....Read More

Frequently Asked Questions

What are plastics and how are they made?

Plastics are synthetic materials made from polymers, which are large molecules composed of repeating structural units called monomers. These monomers are typically derived from petrochemicals, although some bioplastics are made from renewable resources like corn starch or sugarcane.

The production of plastics involves several key steps:

1. **Polymerization**: This is the chemical process where monomers are chemically bonded to form polymer chains. There are two main types of polymerization: addition polymerization, where monomers add to each other without the loss of any molecule, and condensation polymerization, where monomers join together with the elimination of small molecules like water.

2. **Compounding**: The raw polymer is mixed with additives to enhance properties such as color, flexibility, strength, and resistance to UV light or fire. Additives can include plasticizers, stabilizers, fillers, and colorants.

3. **Forming**: The compounded plastic is then shaped into products through various methods. Common forming techniques include:

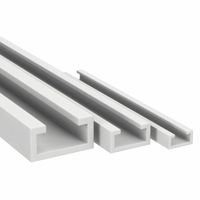

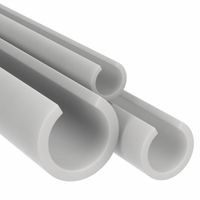

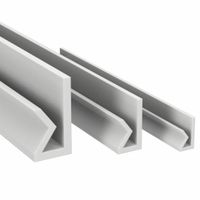

- **Extrusion**: The plastic is melted and forced through a die to create long shapes like pipes or sheets.

- **Injection Molding**: The plastic is melted and injected into a mold to form complex shapes.

- **Blow Molding**: Air is blown into a heated plastic tube to form hollow objects like bottles.

- **Thermoforming**: A plastic sheet is heated and shaped over a mold.

4. **Finishing**: The formed plastic products may undergo additional processes such as cutting, painting, or assembling to achieve the final product specifications.

Plastics are versatile, lightweight, and durable, making them suitable for a wide range of applications, from packaging and construction to electronics and automotive industries. However, their environmental impact, particularly in terms of waste and pollution, has led to increased interest in recycling and biodegradable alternatives.

What are the different types of plastics and their uses?

1. **Polyethylene Terephthalate (PET or PETE):** Commonly used in beverage bottles, food containers, and synthetic fibers. It is lightweight, strong, and recyclable.

2. **High-Density Polyethylene (HDPE):** Utilized in milk jugs, detergent bottles, and plastic bags. Known for its strength and resistance to moisture.

3. **Polyvinyl Chloride (PVC):** Found in pipes, cable insulation, and medical equipment. It is durable and resistant to environmental degradation.

4. **Low-Density Polyethylene (LDPE):** Used in grocery bags, shrink wraps, and squeezable bottles. It is flexible and has a high resistance to moisture.

5. **Polypropylene (PP):** Employed in automotive parts, food containers, and textiles. It is tough, resistant to chemicals, and has a high melting point.

6. **Polystyrene (PS):** Common in disposable cutlery, CD cases, and insulation materials. It is lightweight and can be either rigid or foamed.

7. **Polycarbonate (PC):** Used in eyewear lenses, electronic components, and bulletproof glass. It is strong, transparent, and impact-resistant.

8. **Acrylonitrile Butadiene Styrene (ABS):** Found in LEGO bricks, automotive parts, and consumer electronics. It is tough and resistant to impact.

9. **Polylactic Acid (PLA):** A biodegradable plastic used in 3D printing, disposable tableware, and medical implants. It is derived from renewable resources like corn starch.

10. **Nylon (Polyamide):** Utilized in textiles, automotive components, and industrial applications. It is strong, elastic, and resistant to abrasion.

11. **Polyurethane (PU):** Found in foam seating, insulation panels, and footwear. It is versatile, with applications ranging from flexible to rigid forms.

12. **Polyethylene (PE):** Used in containers, toys, and plastic films. It is versatile, with variations like HDPE and LDPE offering different properties.

How do plastics impact the environment?

Plastics significantly impact the environment through pollution, wildlife harm, and resource depletion. They are non-biodegradable, persisting for hundreds of years, leading to accumulation in landfills and natural habitats. This persistence results in soil and water contamination as plastics break down into microplastics, which infiltrate ecosystems and food chains, affecting both terrestrial and aquatic life.

Marine environments are particularly vulnerable, with millions of tons of plastic waste entering oceans annually. This debris harms marine animals through ingestion and entanglement, leading to injury or death. Sea turtles, birds, and fish often mistake plastic for food, causing blockages, malnutrition, and exposure to toxic substances. The presence of plastics in oceans also disrupts habitats, such as coral reefs, and affects the health of marine ecosystems.

Plastics contribute to climate change through their lifecycle, from production to disposal. The manufacturing process is energy-intensive, relying heavily on fossil fuels, which emit greenhouse gases. Incineration of plastic waste releases carbon dioxide and other pollutants, exacerbating air pollution and climate change.

Furthermore, plastics impact human health. Microplastics have been found in drinking water, food, and even the air, posing potential risks to human health. Chemicals used in plastic production, such as phthalates and bisphenol A (BPA), can leach into the environment and are linked to health issues, including hormonal disruptions and cancer.

Efforts to mitigate plastic pollution include reducing plastic use, improving waste management, promoting recycling, and developing biodegradable alternatives. However, addressing the environmental impact of plastics requires global cooperation and systemic changes in production, consumption, and waste management practices.

What are the benefits of using plastics in manufacturing?

Plastics offer numerous benefits in manufacturing, making them a preferred material across various industries. Firstly, plastics are lightweight, which reduces transportation costs and energy consumption during shipping. This characteristic also contributes to the production of lighter products, enhancing fuel efficiency in automotive and aerospace applications.

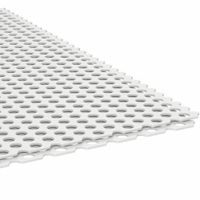

Secondly, plastics are highly versatile and can be molded into complex shapes, allowing for innovative designs and the integration of multiple components into a single part. This reduces assembly time and costs. The versatility extends to a wide range of properties, such as flexibility, rigidity, transparency, and resistance to impact, chemicals, and weather, making plastics suitable for diverse applications.

Thirdly, plastics are cost-effective. They are generally cheaper to produce than metals or glass, and their durability reduces the need for frequent replacements. The low cost of raw materials and the efficiency of plastic manufacturing processes contribute to overall cost savings.

Additionally, plastics offer excellent insulation properties, both thermal and electrical, making them ideal for use in electronics and construction. Their resistance to corrosion and moisture further enhances their suitability for outdoor and marine applications.

Plastics also contribute to sustainability efforts. Many plastics are recyclable, and advancements in recycling technologies are improving the efficiency and feasibility of plastic recycling. Biodegradable and bio-based plastics are being developed to reduce environmental impact.

Finally, the use of plastics in manufacturing supports innovation and rapid prototyping. 3D printing with plastics allows for quick and cost-effective production of prototypes, facilitating faster product development cycles.

In summary, the benefits of using plastics in manufacturing include their lightweight nature, versatility, cost-effectiveness, durability, insulation properties, and potential for recycling, all of which contribute to efficient and innovative production processes.

How can plastics be recycled?

Plastics can be recycled through several key processes, each designed to handle different types of plastic materials. The recycling process generally begins with collection, where plastics are gathered from households, businesses, and recycling centers. Once collected, the plastics are sorted by type and color, often using automated systems like infrared sensors, to ensure that the recycling process is efficient and effective.

After sorting, the plastics are cleaned to remove impurities such as labels, adhesives, and food residues. This step is crucial to ensure the quality of the recycled material. The cleaned plastics are then shredded into small pieces, which increases the surface area and makes them easier to process.

The shredded plastic is then melted and reformed into pellets, a process known as reprocessing. These pellets can be used as raw material for manufacturing new plastic products. Some recycling processes involve chemical recycling, where plastics are broken down into their basic chemical components. This method is particularly useful for plastics that are difficult to recycle mechanically, such as multi-layered materials.

Advanced recycling technologies, like pyrolysis and gasification, convert plastics into fuels or feedstocks for new plastics, offering a way to recycle materials that are otherwise non-recyclable. Additionally, innovations in biodegradable plastics and bioplastics are emerging, which can be composted or broken down by natural processes, reducing the environmental impact.

Recycling plastics not only conserves resources and reduces landfill waste but also decreases energy consumption and greenhouse gas emissions compared to producing new plastics from raw materials. However, the effectiveness of plastic recycling depends on factors like consumer participation, technological advancements, and the economic viability of recycling processes.

What are the health risks associated with plastics?

Plastics pose several health risks due to their chemical composition and environmental persistence. Many plastics contain additives like phthalates and bisphenol A (BPA), which can leach into food and beverages, especially when heated. These chemicals are endocrine disruptors, interfering with hormone function and potentially leading to reproductive issues, developmental problems in children, and increased cancer risk.

Microplastics, tiny plastic particles resulting from the breakdown of larger plastic items, are pervasive in the environment and can enter the human body through ingestion, inhalation, and dermal contact. Once inside the body, microplastics can cause inflammation, oxidative stress, and cellular damage. They may also act as carriers for other toxic substances, such as heavy metals and persistent organic pollutants, further exacerbating health risks.

Occupational exposure to plastic manufacturing processes can lead to respiratory issues, skin irritation, and increased cancer risk due to inhalation of plastic dust and fumes. Additionally, burning plastics releases toxic substances like dioxins and furans, which are highly carcinogenic and can cause respiratory and cardiovascular diseases.

Improper disposal and accumulation of plastic waste in the environment contribute to pollution, affecting ecosystems and human health. Contaminated water sources and soil can lead to the bioaccumulation of harmful chemicals in the food chain, impacting human health through consumption of contaminated food and water.

Overall, the health risks associated with plastics are multifaceted, involving direct chemical exposure, environmental contamination, and long-term ecological impacts. Reducing plastic use, improving waste management, and developing safer alternatives are crucial steps in mitigating these health risks.

How do plastics compare to other materials in terms of durability and cost?

Plastics are known for their exceptional durability and cost-effectiveness compared to many other materials. In terms of durability, plastics are resistant to corrosion, chemicals, and environmental factors such as moisture and UV radiation, which makes them ideal for long-term use in various applications. Unlike metals, plastics do not rust, and unlike wood, they do not rot or degrade easily. This resistance to degradation contributes to their longevity, making them suitable for products that require a long lifespan, such as piping, automotive parts, and outdoor furniture.

In terms of cost, plastics are generally less expensive to produce and process than metals and ceramics. The raw materials for plastics, primarily derived from petrochemicals, are abundant and relatively cheap. Additionally, the manufacturing processes for plastics, such as injection molding and extrusion, are highly efficient and scalable, further reducing production costs. This cost advantage makes plastics a preferred choice for mass-produced consumer goods, packaging, and disposable items.

However, the comparison with other materials can vary depending on the specific type of plastic and its intended use. For instance, high-performance engineering plastics may be more expensive than standard plastics but still offer a cost advantage over metals in certain applications due to their lightweight and ease of fabrication.

While plastics offer significant benefits in terms of durability and cost, they also pose environmental challenges, particularly in terms of waste management and pollution. Unlike biodegradable materials, most plastics do not decompose naturally, leading to long-term environmental impacts. This has prompted increased interest in developing biodegradable plastics and improving recycling technologies to mitigate these issues.

What are biodegradable plastics and how do they work?

Biodegradable plastics are a type of plastic designed to break down more quickly than traditional plastics through the action of microorganisms. They are made from renewable raw materials, micro-organisms, petrochemicals, or combinations thereof. The primary goal of biodegradable plastics is to reduce the environmental impact associated with plastic waste.

These plastics work by undergoing a process called biodegradation, where microorganisms such as bacteria, fungi, and algae metabolize the plastic material, breaking it down into natural substances like water, carbon dioxide, and biomass. The rate and extent of biodegradation depend on environmental conditions such as temperature, presence of microorganisms, and the chemical structure of the plastic.

There are two main types of biodegradable plastics:

1. **Bioplastics**: These are derived from renewable biological sources, such as corn starch, sugarcane, or cellulose. Examples include polylactic acid (PLA) and polyhydroxyalkanoates (PHA). They are designed to decompose in industrial composting facilities.

2. **Petroleum-based biodegradable plastics**: These are made from petrochemicals but are engineered to break down more quickly than conventional plastics. An example is polybutylene adipate terephthalate (PBAT).

Biodegradable plastics are often used in applications where traditional plastics are problematic, such as single-use items like packaging, cutlery, and agricultural films. However, their effectiveness depends on proper disposal and environmental conditions. For instance, some require industrial composting facilities to degrade efficiently and may not break down in natural environments like oceans or landfills.

While biodegradable plastics offer a potential solution to plastic pollution, they are not a panacea. Proper waste management, consumer education, and infrastructure development are crucial to maximizing their environmental benefits.

How is plastic waste managed globally?

Plastic waste management globally involves several strategies:

1. **Recycling**: This is the process of collecting and processing plastic waste to create new products. Countries like Germany and Sweden have advanced recycling systems, achieving high recycling rates. However, globally, only about 9% of plastic is recycled due to contamination and economic factors.

2. **Landfilling**: Many countries still rely on landfills for plastic waste disposal. This method is prevalent in regions with ample land space but poses environmental risks, such as soil and water contamination.

3. **Incineration**: Some countries, like Japan and Denmark, use incineration to manage plastic waste. This process reduces waste volume and can generate energy. However, it can release toxic emissions if not properly managed.

4. **Exporting Waste**: Developed countries often export plastic waste to developing nations for recycling or disposal. This practice has faced criticism due to environmental and ethical concerns, leading to stricter regulations and bans in countries like China and Malaysia.

5. **Biodegradable Plastics**: The development and use of biodegradable plastics aim to reduce the environmental impact. These materials break down more easily but require specific conditions to decompose effectively.

6. **Legislation and Bans**: Many countries have implemented bans on single-use plastics and introduced policies to reduce plastic production and consumption. The European Union, for example, has banned certain single-use plastic items.

7. **Public Awareness and Education**: Global campaigns and initiatives aim to raise awareness about plastic pollution and promote sustainable practices among consumers and industries.

8. **Innovative Technologies**: New technologies, such as chemical recycling and waste-to-fuel processes, are being developed to improve plastic waste management.

Overall, effective plastic waste management requires a combination of these strategies, international cooperation, and a shift towards a circular economy.

What innovations are being made in the field of plastics?

Innovations in the field of plastics are focusing on sustainability, biodegradability, and enhanced functionality. Bioplastics, derived from renewable sources like corn starch and sugarcane, are gaining traction as they reduce reliance on fossil fuels. Companies are developing biodegradable plastics that decompose more quickly in natural environments, addressing pollution concerns. Innovations in chemical recycling are enabling the breakdown of plastics into their original monomers, allowing for the creation of new plastics without quality loss.

Researchers are also exploring the use of enzymes and microbes to accelerate plastic degradation. For instance, engineered enzymes can break down PET plastics in a matter of hours. In terms of functionality, smart plastics are being developed with embedded sensors and electronic capabilities for use in packaging and medical devices. Nanotechnology is being applied to enhance the strength, durability, and thermal resistance of plastics, making them suitable for more demanding applications.

Additionally, there is a push towards creating closed-loop systems where plastics are continuously recycled and reused, minimizing waste. Innovations in additive manufacturing, or 3D printing, are allowing for the creation of complex plastic structures with minimal material waste. Efforts are also being made to improve the recyclability of multi-layered plastics, which are traditionally difficult to process.

Overall, the focus is on creating plastics that are not only environmentally friendly but also meet the evolving needs of various industries, from packaging to automotive and electronics.