Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Fiberglass Carbon Fiber Composites

- Structural Fiberglass Reinforced Plastics

- Fiberglass Grating Stair Treads Accessories

.....Read More

Frequently Asked Questions

What are the benefits of using fiberglass grating?

Fiberglass grating offers several benefits, making it a popular choice in various industries. Firstly, it is highly resistant to corrosion, which makes it ideal for use in environments exposed to chemicals, moisture, and extreme weather conditions. This durability extends the lifespan of the grating, reducing maintenance and replacement costs.

Secondly, fiberglass grating is lightweight compared to traditional materials like steel or aluminum. This ease of handling and installation can lead to reduced labor costs and quicker project completion times. Despite its light weight, it maintains high strength and load-bearing capacity, making it suitable for heavy-duty applications.

Additionally, fiberglass grating is non-conductive, providing a safer option in environments where electrical hazards are a concern. This property is particularly beneficial in industries such as electrical, telecommunications, and transportation.

The material also offers excellent slip resistance, enhancing safety in wet or oily conditions. This is achieved through a textured surface that provides better traction, reducing the risk of slips and falls.

Fiberglass grating is available in a variety of colors and styles, allowing for customization to meet specific aesthetic or functional requirements. It can be molded or pultruded to fit different applications, offering flexibility in design.

Moreover, fiberglass grating is resistant to UV radiation, which prevents degradation and maintains its structural integrity and appearance over time. It is also fire-retardant, adding an extra layer of safety in environments where fire risk is a concern.

Finally, fiberglass grating is environmentally friendly, as it can be manufactured using recycled materials and is itself recyclable. This sustainability aspect is increasingly important in modern construction and industrial practices.

How do you install fiberglass grating clips?

1. **Preparation**: Ensure the grating and support structure are clean and free of debris. Gather necessary tools such as a wrench, screwdriver, or drill, depending on the clip type.

2. **Select Clip Type**: Choose the appropriate clip for your application. Common types include M-clips, C-clips, and G-clips, each designed for different support structures and load requirements.

3. **Position the Grating**: Place the fiberglass grating on the support structure, ensuring it is properly aligned and positioned.

4. **Locate Clip Positions**: Identify the points where clips will be installed. Typically, clips are placed at each corner and at intervals along the edges and center, depending on the grating size and load requirements.

5. **Install Clips**:

- **M-Clips**: Position the M-clip over the grating bar and align it with the support structure. Insert the bolt through the clip and tighten it into the pre-drilled hole in the support structure.

- **C-Clips**: Place the C-clip under the grating bar, aligning it with the support structure. Insert the bolt through the clip and tighten it into the support structure.

- **G-Clips**: Position the G-clip over the grating bar, ensuring the bottom part hooks under the support structure. Tighten the bolt to secure the clip.

6. **Tighten Clips**: Use a wrench or screwdriver to tighten the bolts securely, ensuring the grating is firmly attached to the support structure without over-tightening, which could damage the grating.

7. **Inspection**: Check all clips to ensure they are properly installed and secure. Adjust as necessary to ensure stability and safety.

8. **Final Check**: Walk over the grating to ensure it is stable and does not shift, indicating that the clips are properly installed.

What are the applications of fiberglass grating in industrial settings?

Fiberglass grating is widely used in industrial settings due to its durability, corrosion resistance, and lightweight properties. Here are some key applications:

1. **Chemical Processing Plants**: Fiberglass grating is ideal for environments exposed to corrosive chemicals. It is used for flooring, walkways, and platforms, providing a safe, non-slip surface that withstands chemical exposure.

2. **Oil and Gas Industry**: In offshore and onshore facilities, fiberglass grating is used for walkways, stair treads, and platforms. Its resistance to saltwater and chemicals makes it suitable for harsh marine environments.

3. **Water and Wastewater Treatment**: The non-corrosive nature of fiberglass grating makes it perfect for use in water treatment plants. It is used for walkways, platforms, and covers over tanks and channels.

4. **Food and Beverage Industry**: Fiberglass grating is used in areas requiring hygiene and cleanliness. It is easy to clean and does not harbor bacteria, making it suitable for food processing areas.

5. **Mining Industry**: Used for walkways and platforms, fiberglass grating provides a safe, non-slip surface in mining operations. Its lightweight nature allows for easy installation and maintenance.

6. **Pulp and Paper Industry**: The grating is used in wet and corrosive environments typical of pulp and paper mills, providing durable and safe access solutions.

7. **Power Generation**: In power plants, fiberglass grating is used for walkways and platforms due to its electrical non-conductivity and resistance to heat and chemicals.

8. **Transportation**: Used in railway and airport facilities for platforms and walkways, fiberglass grating offers a durable, non-slip surface that withstands heavy foot traffic.

9. **Marine Applications**: Ideal for docks, piers, and ship decks, fiberglass grating resists saltwater corrosion and provides a safe, non-slip surface.

These applications highlight the versatility and reliability of fiberglass grating in various industrial environments.

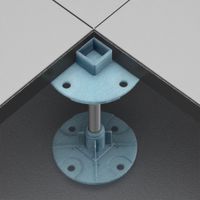

How do you adjust pedestals for fiberglass grating?

To adjust pedestals for fiberglass grating, follow these steps:

1. **Site Preparation**: Ensure the area is clean and level. Remove debris and ensure the surface is stable to support the pedestals.

2. **Layout Planning**: Determine the layout of the grating panels. Mark the positions where each pedestal will be placed, ensuring they align with the grating's support points.

3. **Pedestal Placement**: Position the pedestals at the marked locations. Ensure they are evenly spaced to provide uniform support across the grating.

4. **Height Adjustment**: Adjust the height of each pedestal to achieve the desired elevation. Most pedestals have a threaded mechanism or shims for height adjustment. Rotate the threaded section or add/remove shims to reach the correct height.

5. **Leveling**: Use a spirit level to ensure each pedestal is level. Adjust as necessary to maintain a flat and even surface for the grating.

6. **Secure Pedestals**: Once the height and level are set, secure the pedestals in place. This may involve tightening locking nuts or using adhesive, depending on the pedestal design.

7. **Install Grating**: Place the fiberglass grating panels onto the pedestals. Ensure they are properly aligned and seated on the support points.

8. **Final Adjustments**: Check the overall level of the installed grating. Make any final adjustments to the pedestals to ensure a uniform surface.

9. **Secure Grating**: Fasten the grating to the pedestals using clips or fasteners as recommended by the manufacturer to prevent movement.

10. **Inspection**: Conduct a final inspection to ensure stability and proper installation. Check for any uneven areas or loose components and rectify them.

This process ensures a stable and level installation of fiberglass grating using adjustable pedestals.

What are the safety features of fiberglass stair treads?

Fiberglass stair treads offer several safety features that make them a preferred choice in various environments:

1. **Slip Resistance**: Fiberglass stair treads are designed with a textured surface that provides excellent slip resistance, even in wet or oily conditions. This feature is crucial for preventing accidents and ensuring safe footing.

2. **Corrosion Resistance**: Unlike metal treads, fiberglass does not corrode, making it ideal for use in environments exposed to moisture, chemicals, or saltwater. This resistance ensures the treads maintain their structural integrity and safety over time.

3. **High Visibility**: Many fiberglass stair treads come with contrasting colors or embedded grit strips that enhance visibility. This feature helps in clearly defining the edges of the steps, reducing the risk of missteps.

4. **Fire Retardant**: Fiberglass materials can be treated to be fire retardant, providing an added layer of safety in case of a fire. This feature is particularly important in industrial settings where fire hazards may be present.

5. **Impact Resistance**: Fiberglass stair treads are highly durable and can withstand significant impact without cracking or breaking. This durability ensures that the treads remain safe and functional even under heavy use.

6. **Non-Conductive**: Fiberglass is non-conductive, making it a safe choice in environments where electrical hazards are a concern. This feature protects users from electrical shocks.

7. **Lightweight**: Despite their strength, fiberglass stair treads are lightweight, which makes them easier and safer to install and handle compared to heavier materials like metal or concrete.

8. **Low Maintenance**: The low maintenance requirement of fiberglass stair treads ensures that they remain safe and effective without the need for frequent repairs or replacements.

These features collectively contribute to the safety and reliability of fiberglass stair treads in various applications.

How do you maintain and clean fiberglass grating?

To maintain and clean fiberglass grating, follow these steps:

1. **Regular Inspection**: Periodically inspect the grating for any signs of damage, wear, or accumulation of debris. Look for cracks, chips, or any structural weaknesses.

2. **Cleaning**:

- **Debris Removal**: Use a broom or a leaf blower to remove loose debris like leaves, dirt, and dust.

- **Washing**: For more thorough cleaning, use a pressure washer with a mild detergent solution. Ensure the pressure is not too high to avoid damaging the grating.

- **Stain Removal**: For stubborn stains, apply a non-abrasive cleaner or a mixture of water and mild detergent. Use a soft-bristle brush to scrub the surface gently.

- **Rinsing**: Rinse thoroughly with clean water to remove any soap residue.

3. **Mold and Mildew**: If mold or mildew is present, apply a solution of water and vinegar or a commercial mold remover. Allow it to sit for a few minutes before scrubbing and rinsing.

4. **Repairs**: Address any minor damages immediately. Small cracks or chips can be repaired using a fiberglass repair kit. For significant damage, consider replacing the affected sections.

5. **Preventive Measures**:

- **Non-Slip Coating**: Apply a non-slip coating to enhance safety and protect the surface.

- **UV Protection**: Use a UV-resistant coating to prevent fading and degradation from sun exposure.

6. **Avoid Harsh Chemicals**: Do not use harsh chemicals or abrasive tools that can damage the fiberglass surface.

7. **Documentation**: Keep a maintenance log to track inspections, cleaning, and repairs.

By following these steps, you can ensure the longevity and safety of fiberglass grating.

What are the different types of fiberglass grating available?

Fiberglass grating is available in several types, each designed for specific applications and environments:

1. **Molded Grating**: This type is made by laying continuous glass fibers in a mold, which is then filled with resin. It offers bi-directional strength and is ideal for applications requiring corrosion resistance and a high strength-to-weight ratio. Molded grating is often used in chemical plants, food processing facilities, and wastewater treatment plants.

2. **Pultruded Grating**: Manufactured by pulling continuous fiberglass strands through a resin bath and then through a heated die, pultruded grating provides high unidirectional strength. It is suitable for applications needing long spans and is commonly used in industrial flooring, walkways, and platforms.

3. **Covered Grating**: This type features a solid top surface, providing a smooth walking surface and preventing objects from falling through. It is used in areas where a closed surface is necessary, such as food processing or areas requiring easy cleaning.

4. **Phenolic Grating**: Made with phenolic resin, this grating type offers superior fire resistance and low smoke emissions. It is used in offshore platforms, ships, and other environments where fire safety is a critical concern.

5. **Conductive Grating**: Designed to dissipate static electricity, conductive grating is used in environments where static discharge could be hazardous, such as in electronics manufacturing or explosive environments.

6. **Mini-Mesh Grating**: Featuring smaller openings, mini-mesh grating provides a more comfortable walking surface and is suitable for pedestrian areas, especially those with high-heeled traffic.

7. **Heavy-Duty Grating**: Engineered for high-load applications, heavy-duty grating is used in areas with vehicular traffic or heavy equipment, such as loading docks and industrial floors.

Each type of fiberglass grating offers unique benefits tailored to specific industrial needs, ensuring safety, durability, and performance in various environments.