- Home

- Pneumatics

- Vacuum System Components

.....Read More

Cobotic End-of-Arm Vacuum Tool Extensions

Cobotic Mounting & Quick-Change Components

Cobotic Tool Changers & Tool Mounts

Cobotic Vacuum System End Effectors

Magnetic Grippers for Vacuum Systems

Vacuum Area Gripping Systems

Vacuum Buffers

Vacuum Generators

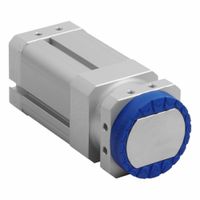

Vacuum Generators with Gripper Assembly

Vacuum Gripper Integration Kits

Vacuum Pad Adapters

Vacuum Pads & Pad Assemblies

Vacuum Pressure Switches

Vacuum Regulators

Vacuum Saving Valves

Vacuum Suction Filters

Vacuum Water Separators

Frequently Asked Questions

What are the main components of a vacuum system for material handling?

How do vacuum generators work in air-operated systems?

What types of vacuum cups are available for different applications?

How do you select the right vacuum cup for a specific workpiece?

What role do vacuum buffers play in automated systems?

How do vacuum valves control the flow in a vacuum system?

What are the benefits of using vacuum systems in automated assembly?

How do you maintain and troubleshoot vacuum system components?

What safety considerations should be taken when using vacuum systems?

How do you optimize the efficiency of a vacuum system in material handling?