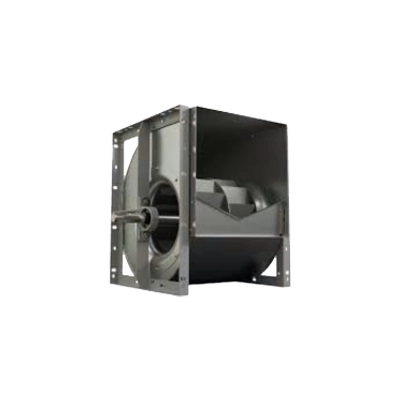

Forward-curved blowers, also known as forward-curved centrifugal fans, are best suited for applications requiring high airflow at low to medium static pressures. They are commonly used in HVAC systems, including residential and commercial heating, ventilation, and air conditioning, due to their ability to move large volumes of air efficiently. These blowers are ideal for ducted systems where the resistance to airflow is relatively low.

In addition to HVAC systems, forward-curved blowers are used in air handling units, air curtains, and air purifiers. They are also suitable for applications in industrial processes where large volumes of air need to be circulated or exhausted, such as in paint booths, drying ovens, and fume extraction systems.

Forward-curved blowers are often employed in situations where noise levels need to be minimized, as they generally operate more quietly than other types of fans. This makes them suitable for use in environments where noise reduction is important, such as in office buildings, hospitals, and schools.

These blowers are also used in applications where space is limited, as their compact design allows for installation in confined areas. Additionally, they are often chosen for systems that require variable speed control, as they can be easily adjusted to meet changing airflow demands.

Overall, forward-curved blowers are best suited for applications that prioritize high airflow, low noise, and compact design, making them a versatile choice for a wide range of residential, commercial, and industrial applications.