Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Packaging Shipping

- Protective Packaging

- Anti Static Packaging

.....Read More

Frequently Asked Questions

What are anti-static packaging materials?

Anti-static packaging materials are specialized materials designed to prevent the buildup of static electricity, which can damage sensitive electronic components during storage, handling, and transportation. These materials are crucial in industries where electronic components, such as semiconductors, circuit boards, and other electronic devices, are manufactured and distributed.

Static electricity is a common phenomenon that occurs when there is an imbalance of electric charges within or on the surface of a material. This can lead to electrostatic discharge (ESD), which can cause significant damage to electronic components by altering their electrical characteristics or even destroying them. Anti-static packaging materials help mitigate this risk by dissipating static charges safely.

There are several types of anti-static packaging materials, each serving a specific purpose:

1. **Anti-static Bags**: These are typically made from polyethylene or polypropylene and are treated to prevent static buildup. They are often used for storing and transporting electronic components.

2. **Conductive Bags**: Made from materials that conduct electricity, these bags provide a Faraday cage effect, protecting the contents from external static charges.

3. **Static Shielding Bags**: These bags have multiple layers, including a conductive layer, to shield the contents from static fields.

4. **Foams and Cushions**: Anti-static foams and cushioning materials are used to protect components from physical damage while also preventing static buildup.

5. **Bubble Wrap**: Anti-static bubble wrap is treated to prevent static electricity and is used for wrapping and protecting delicate electronic items.

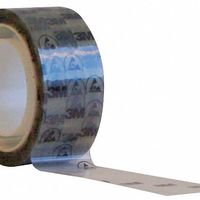

6. **Tapes and Labels**: Anti-static tapes and labels are used to seal packages and provide identification without generating static.

These materials are essential in maintaining the integrity and functionality of electronic components throughout the supply chain, ensuring that they reach the end-user without damage from static electricity.

How do anti-static packaging materials work?

Anti-static packaging materials work by preventing the buildup and discharge of static electricity, which can damage sensitive electronic components. These materials are designed to either dissipate static charges or shield the contents from external static fields.

1. **Material Composition**: Anti-static materials are typically made from polyethylene or polypropylene, which are treated with anti-static agents. These agents can be either incorporated into the material during manufacturing or applied as a coating. The agents reduce the surface resistivity, allowing static charges to dissipate more quickly.

2. **Dissipative Properties**: Anti-static materials have a controlled surface resistivity, usually between 10^6 to 10^11 ohms/square. This range allows the material to slowly dissipate static charges without causing a sudden discharge that could damage electronic components.

3. **Conductive Layers**: Some anti-static packaging includes a conductive layer, often made of carbon or metal, which provides a path for static charges to flow away from the sensitive items. This layer can be part of a multi-layer structure, with the conductive layer sandwiched between insulating layers.

4. **Shielding Effect**: Anti-static bags, for example, often have a metallic layer that acts as a Faraday cage, shielding the contents from external static fields. This prevents external static charges from reaching the sensitive components inside.

5. **Humidity Control**: Some anti-static materials are designed to maintain a certain level of humidity, which helps reduce static buildup. Moisture in the air increases the conductivity of the material, aiding in the dissipation of static charges.

By combining these properties, anti-static packaging materials protect electronic components from electrostatic discharge (ESD) during storage and transportation, ensuring their functionality and longevity.

Why is anti-static packaging important for electronics?

Anti-static packaging is crucial for electronics because it protects sensitive components from electrostatic discharge (ESD), which can cause immediate or latent damage. ESD occurs when there is a sudden flow of electricity between two electrically charged objects, often due to contact or a short circuit. This discharge can generate voltages high enough to damage electronic circuits, even if the human body cannot feel it.

Electronic components, especially integrated circuits and semiconductors, are highly susceptible to ESD. Damage from ESD can lead to device failure, reduced performance, or shortened lifespan. Anti-static packaging materials, such as bags, foams, and wraps, are designed to prevent the buildup of static electricity and safely dissipate any charges that do occur.

These packaging materials are typically made from conductive or dissipative materials that either shield the contents from external static fields or prevent the generation of static charges. Conductive materials allow charges to flow through them, while dissipative materials slow down the flow, reducing the risk of a sudden discharge.

Using anti-static packaging is essential during manufacturing, shipping, and storage of electronic components. It ensures that the components remain in optimal condition until they are installed in their final application. This protection is vital for maintaining product reliability and reducing the risk of costly failures or recalls.

In summary, anti-static packaging is important for electronics because it safeguards against ESD, ensuring the integrity and functionality of electronic components throughout their lifecycle.

What is the difference between anti-static and regular packaging?

Anti-static packaging is specifically designed to prevent the buildup of static electricity, which can damage sensitive electronic components. It is made from materials that either dissipate static charges or shield the contents from external static fields. Common types include anti-static bags, bubble wrap, and foam, often treated with anti-static agents or made from inherently conductive materials. These packages are crucial for transporting and storing electronic components like circuit boards, semiconductors, and other sensitive devices.

Regular packaging, on the other hand, is designed primarily for protection against physical damage, environmental factors, and contamination during storage and transportation. It does not have the properties to prevent static electricity buildup or protect against electrostatic discharge (ESD). Materials used in regular packaging include cardboard, plastic, and paper, which can generate static charges and are unsuitable for sensitive electronics.

The key difference lies in their purpose and material properties: anti-static packaging is engineered to manage static electricity, while regular packaging focuses on general protection without addressing static concerns.

Can anti-static packaging be reused?

Yes, anti-static packaging can be reused, but there are several factors to consider. Anti-static packaging, such as bags and bubble wrap, is designed to protect electronic components from electrostatic discharge (ESD) during storage and transportation. These materials are typically made from polyethylene with an anti-static coating or additive that dissipates static electricity.

Reusability depends on the condition of the packaging. If the anti-static properties are intact and the packaging is not physically damaged, it can be reused multiple times. However, over time and with repeated use, the anti-static properties may degrade, reducing their effectiveness. It's important to inspect the packaging for any signs of wear, such as tears, punctures, or loss of anti-static coating, before reuse.

When reusing anti-static packaging, ensure that it is clean and free from contaminants that could harm electronic components. Additionally, consider the specific requirements of the components being stored or transported. Some sensitive components may require new packaging to ensure maximum protection.

In summary, while anti-static packaging can be reused, it is crucial to regularly assess its condition and effectiveness to ensure continued protection against ESD.

How to choose the right anti-static packaging for my needs?

To choose the right anti-static packaging, consider the following factors:

1. **Type of Product**: Identify the sensitivity of your product to static electricity. Highly sensitive electronic components require more robust anti-static protection.

2. **Material**: Choose between anti-static bags, bubble wrap, or foam. Anti-static bags are ideal for small components, while bubble wrap and foam offer cushioning for larger items.

3. **Level of Protection**: Determine if you need static shielding, anti-static, or conductive packaging. Static shielding provides the highest level of protection, while anti-static materials prevent static build-up.

4. **Environment**: Consider the environment where the product will be stored or transported. High humidity or temperature variations may require more durable materials.

5. **Size and Shape**: Ensure the packaging fits the product snugly to prevent movement and potential damage.

6. **Cost**: Balance the cost with the level of protection needed. Higher protection levels may incur higher costs but are necessary for sensitive items.

7. **Compliance**: Ensure the packaging meets industry standards and regulations for static protection.

8. **Reusability**: Consider if reusable packaging is beneficial for your operations, especially for frequent shipments.

9. **Supplier Reputation**: Choose a reputable supplier known for quality anti-static products.

10. **Customization**: If standard options do not meet your needs, look for suppliers who offer custom solutions.

By evaluating these factors, you can select the most appropriate anti-static packaging to protect your products effectively.

Where can I buy anti-static packaging materials?

You can purchase anti-static packaging materials from a variety of sources:

1. **Online Retailers**: Websites like Amazon, eBay, and Alibaba offer a wide range of anti-static packaging materials, including bags, bubble wrap, and foam. These platforms provide customer reviews and ratings to help you make informed decisions.

2. **Specialty Packaging Suppliers**: Companies such as Uline, Grainger, and RS Components specialize in packaging materials and offer anti-static options. They provide detailed product specifications and bulk purchasing options.

3. **Electronics Stores**: Retailers like Best Buy or Fry's Electronics may carry anti-static bags and other materials, especially in their computer or accessories sections.

4. **Office Supply Stores**: Chains like Staples or Office Depot sometimes stock anti-static packaging materials, particularly in their shipping and mailing sections.

5. **Local Electronics Shops**: Smaller, independent electronics stores often carry anti-static materials, especially if they cater to computer enthusiasts or repair services.

6. **Industrial Suppliers**: Companies like Digi-Key or Mouser Electronics supply anti-static materials for industrial and commercial use, often with a focus on electronics manufacturing.

7. **Custom Packaging Companies**: For specific needs, custom packaging companies can design and produce anti-static materials tailored to your requirements.

8. **Wholesale Distributors**: If you need large quantities, consider contacting wholesale distributors who specialize in packaging materials.

9. **Online Marketplaces for Industrial Goods**: Platforms like ThomasNet or GlobalSpec connect buyers with suppliers of industrial goods, including anti-static packaging.

10. **Local Classifieds and Forums**: Websites like Craigslist or specialized forums may have listings for surplus or second-hand anti-static materials.

Always ensure that the materials meet the necessary standards for your specific application to protect sensitive electronic components effectively.