Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

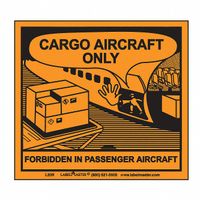

- Packaging Shipping

- Package Labels Shipping Equipment

- Special Handling Labels Placards

- Hazardous Materials Dot Shipping Labels Placards

.....Read More

Frequently Asked Questions

What are the different types of hazmat shipping labels and placards?

Hazmat shipping labels and placards are essential for identifying hazardous materials during transportation. They ensure safety and compliance with regulations. Here are the different types:

1. **Explosives (Class 1):**

- Divided into six divisions (1.1 to 1.6) based on the explosion hazard.

- Labels feature an orange background with a bursting ball symbol.

2. **Gases (Class 2):**

- Includes flammable, non-flammable, and toxic gases.

- Labels are color-coded: red for flammable, green for non-flammable, and white for toxic gases.

3. **Flammable Liquids (Class 3):**

- Labels have a red background with a flame symbol.

4. **Flammable Solids (Class 4):**

- Divided into three divisions: flammable solids, spontaneously combustible, and dangerous when wet.

- Labels vary in color: red and white stripes, white, and blue, respectively.

5. **Oxidizing Substances and Organic Peroxides (Class 5):**

- Oxidizers have a yellow label with a flame over a circle.

- Organic peroxides have a red and yellow label.

6. **Toxic and Infectious Substances (Class 6):**

- Toxic substances have a white label with a skull and crossbones.

- Infectious substances have a white label with a biohazard symbol.

7. **Radioactive Materials (Class 7):**

- Labels are yellow and white with a trefoil symbol.

8. **Corrosives (Class 8):**

- Labels are black and white with a test tube and hand symbol.

9. **Miscellaneous Dangerous Goods (Class 9):**

- Labels are black and white with vertical stripes on the top half.

Each label and placard must display the appropriate hazard class number and adhere to size and design specifications set by regulatory bodies like the DOT and UN.

How do I determine which hazmat label or placard to use for my shipment?

1. **Identify the Material**: Determine the hazardous material's proper shipping name, UN/NA number, and hazard class/division from the Safety Data Sheet (SDS) or the manufacturer.

2. **Consult Regulations**: Refer to the relevant regulations such as the U.S. Department of Transportation (DOT) Hazardous Materials Regulations (HMR), the International Air Transport Association (IATA) Dangerous Goods Regulations, or the International Maritime Dangerous Goods (IMDG) Code.

3. **Determine Hazard Class**: Identify the primary hazard class and any subsidiary risks. Hazard classes range from Class 1 (Explosives) to Class 9 (Miscellaneous).

4. **Use the Hazardous Materials Table**: In the HMR, use the Hazardous Materials Table (49 CFR 172.101) to find the appropriate label or placard for the material based on its UN/NA number and hazard class.

5. **Check Quantity and Packaging**: Determine if the shipment qualifies for any exceptions or requires specific packaging, which may affect labeling and placarding requirements.

6. **Select the Correct Label/Placard**: Based on the hazard class and quantity, select the appropriate label for packages and placard for transport vehicles. Labels are for individual packages, while placards are for transport vehicles carrying certain quantities.

7. **Consider Special Provisions**: Review any special provisions or additional requirements that may apply to the material, such as temperature control or specific handling instructions.

8. **Verify Compatibility**: Ensure that the label or placard is compatible with other materials being shipped to prevent dangerous reactions.

9. **Apply Labels/Placards**: Affix the correct labels to packages and placards to transport vehicles as per regulatory guidelines, ensuring visibility and durability.

10. **Training and Documentation**: Ensure all personnel involved in the shipment are trained in hazmat handling and that all required documentation accompanies the shipment.

What are the regulations for hazmat shipping labels and placards?

Hazmat shipping labels and placards are regulated primarily by the U.S. Department of Transportation (DOT) under the Hazardous Materials Regulations (HMR), found in Title 49 of the Code of Federal Regulations (CFR), Parts 100-185. These regulations are designed to ensure the safe and secure transportation of hazardous materials.

1. **Labels**:

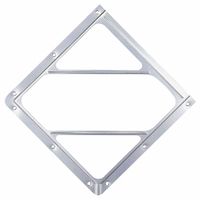

- **Design and Size**: Labels must be diamond-shaped, measuring at least 100 mm (3.9 inches) on each side. They must have a solid line inner border, set 5 mm inside the edge.

- **Color and Symbols**: Specific colors and symbols are designated for different classes of hazardous materials. For example, flammable liquids require a red label with a flame symbol.

- **Text**: Labels must include the hazard class or division number in the bottom corner. Some labels may also require additional text, such as "FLAMMABLE" or "CORROSIVE."

2. **Placards**:

- **Design and Size**: Placards are larger than labels, measuring at least 250 mm (9.84 inches) on each side. They must also have a solid line inner border.

- **Color and Symbols**: Similar to labels, placards use specific colors and symbols to denote the type of hazard. They must be visible from all sides of the transport vehicle.

- **Text and Numbers**: Placards must display the hazard class or division number and may include additional text or the UN identification number.

3. **Placement**:

- Labels must be affixed to the package near the proper shipping name.

- Placards must be placed on all four sides of a transport vehicle or container.

4. **Exceptions and Special Provisions**: Certain materials may have exceptions or require additional markings, as specified in the HMR.

Compliance with these regulations is mandatory to ensure safety and avoid penalties.

How should hazmat labels and placards be displayed on containers and vehicles?

Hazmat labels and placards must be displayed according to specific regulations to ensure safety and compliance. Labels are required on individual packages, while placards are used on transport vehicles.

1. **Labels on Packages:**

- **Placement:** Labels must be placed on the same surface of the package near the proper shipping name and UN number.

- **Visibility:** They should be clearly visible and not obscured by other labels or markings.

- **Durability:** Labels must withstand exposure to weather and handling without deterioration.

- **Size and Design:** Labels must be at least 100 mm x 100 mm, with specific colors and symbols as per the hazard class.

2. **Placards on Vehicles:**

- **Placement:** Placards must be displayed on all four sides of the transport vehicle or freight container.

- **Visibility:** They should be visible from a distance and not obscured by dirt or other materials.

- **Durability:** Placards must be weather-resistant and securely attached.

- **Size and Design:** Standard size is 273 mm x 273 mm, with specific colors, symbols, and numbers indicating the hazard class.

- **Multiple Hazards:** If transporting multiple classes of hazardous materials, each class must be represented by a separate placard unless a "DANGEROUS" placard is permitted.

3. **General Requirements:**

- **Legibility:** Both labels and placards must be legible and in English.

- **Compliance:** Follow regulations from bodies like the U.S. Department of Transportation (DOT) or international standards such as the International Maritime Dangerous Goods (IMDG) Code.

- **Training:** Personnel involved in handling and transporting hazardous materials must be trained in recognizing and understanding these labels and placards.

Proper display ensures quick identification of hazards, facilitating safe handling and emergency response.

What information is required on a hazmat shipping label or placard?

A hazmat shipping label or placard must include the following information:

1. **UN/NA Number**: A four-digit number assigned by the United Nations or North America to identify hazardous materials.

2. **Proper Shipping Name**: The official name of the hazardous material as listed in the hazardous materials table.

3. **Hazard Class or Division Number**: Indicates the primary hazard class of the material, such as Class 1 for explosives or Class 3 for flammable liquids.

4. **Subsidiary Risk**: If applicable, any additional hazard classes that the material may pose.

5. **Packing Group**: Indicates the level of danger, with I being the most dangerous and III being the least.

6. **Handling Instructions**: Any specific instructions for handling the material safely.

7. **Emergency Contact Information**: A phone number or contact information for immediate assistance in case of an emergency.

8. **Compatibility Group Letter**: For explosives, a letter indicating the compatibility group.

9. **Label Codes**: Specific codes that correspond to the hazard class and any subsidiary risks.

10. **Size and Color Requirements**: Labels and placards must meet specific size and color requirements to ensure visibility and recognition.

11. **Symbols and Pictograms**: Standardized symbols that visually represent the type of hazard, such as a flame for flammable materials.

12. **Language Requirements**: The information must be in English and may need to be in additional languages depending on the destination.

13. **Certification Statement**: A declaration that the shipment complies with all applicable regulations.

14. **Shipper's Information**: Name and address of the shipper.

15. **Consignee's Information**: Name and address of the recipient.

These elements ensure that the hazardous materials are transported safely and in compliance with international and national regulations.

How often do hazmat shipping labels and placards need to be updated or replaced?

Hazmat shipping labels and placards must be updated or replaced whenever there is a change in the classification, quantity, or condition of the hazardous material being transported. This includes changes in the hazard class, division, or subsidiary risk, as well as any updates to regulations that affect labeling requirements. Additionally, labels and placards must be replaced if they become damaged, illegible, or detached during transportation.

The U.S. Department of Transportation (DOT) and other international regulatory bodies, such as the International Maritime Organization (IMO) and the International Air Transport Association (IATA), provide specific guidelines on when and how these labels and placards should be updated. For instance, the DOT requires that placards be visible and legible at all times during transportation, and any deterioration that affects their visibility or legibility necessitates immediate replacement.

Furthermore, periodic reviews of the regulations are conducted, and any amendments or updates to the hazardous materials regulations may require changes to the labeling and placarding. Companies involved in the transportation of hazardous materials must stay informed about these regulatory changes to ensure compliance.

In summary, hazmat shipping labels and placards need to be updated or replaced whenever there are changes in the material's classification, regulatory updates, or if they become damaged or illegible. Regular checks and adherence to current regulations are essential to ensure safety and compliance in the transportation of hazardous materials.

What are the penalties for not using proper hazmat shipping labels and placards?

Penalties for not using proper hazmat shipping labels and placards can be severe and vary depending on the jurisdiction and the nature of the violation. In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) enforce these regulations. Penalties can include:

1. **Civil Penalties**: Companies can face substantial fines for each violation. As of 2023, civil penalties can reach up to $89,678 per day, per violation. If the violation results in death, serious illness, or severe injury to any person, or substantial destruction of property, the fines can be significantly higher.

2. **Criminal Penalties**: Willful violations can lead to criminal charges. Individuals responsible for the violation can face fines up to $250,000 and imprisonment for up to five years. For organizations, fines can reach up to $500,000 per violation.

3. **Operational Consequences**: Non-compliance can lead to the suspension or revocation of shipping licenses and permits, disrupting business operations.

4. **Increased Liability**: In the event of an accident, improper labeling can increase liability in lawsuits, as it may be considered negligence.

5. **Reputational Damage**: Companies may suffer reputational harm, leading to loss of business and customer trust.

6. **Corrective Actions**: Companies may be required to take corrective actions, including retraining employees and implementing stricter compliance measures.

7. **Inspection and Delays**: Shipments may be delayed or rejected at checkpoints, leading to logistical challenges and increased costs.

Compliance with hazmat labeling and placarding regulations is crucial to ensure safety, avoid legal repercussions, and maintain operational integrity.