Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

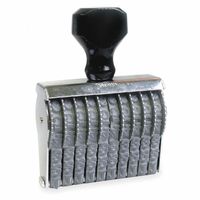

- Office Supplies

- Ink Stamps Ink Pads

.....Read More

Frequently Asked Questions

What are ink stamps and ink pads used for?

Ink stamps and ink pads are tools used for imprinting designs, text, or symbols onto various surfaces. Ink stamps, typically made of rubber or polymer, feature a raised design or text that is pressed onto an ink pad to absorb ink. Once inked, the stamp is pressed onto a surface, transferring the inked design.

Ink stamps and ink pads serve multiple purposes:

1. **Office Use**: In offices, they are used for marking documents with dates, signatures, or approval marks. They help streamline administrative tasks by providing a quick and consistent way to apply necessary information.

2. **Crafting and Art**: In arts and crafts, they are popular for creating decorative patterns on paper, fabric, or other materials. Crafters use them for scrapbooking, card making, and other creative projects, allowing for intricate designs without the need for freehand drawing.

3. **Branding and Marketing**: Businesses use custom ink stamps to brand packaging, promotional materials, or products. This is a cost-effective way to ensure brand visibility and consistency.

4. **Education**: Teachers use stamps to provide feedback on student work, such as grading or giving motivational messages. They are also used in educational activities to engage students in learning.

5. **Personalization**: Individuals use stamps for personalizing stationery, gifts, or correspondence. Custom stamps can include names, addresses, or personal messages.

6. **Legal and Official Use**: In legal and governmental settings, stamps are used to authenticate documents, ensuring they are official and recognized.

Ink pads come in various colors and types, including dye-based, pigment-based, and specialty inks, allowing for different effects and applications. The choice of ink pad depends on the desired outcome and the surface being stamped.

How do you refill an ink pad?

To refill an ink pad, follow these steps:

1. **Gather Materials**: Obtain the correct refill ink for your ink pad. Ensure it matches the type and color of your existing ink pad.

2. **Prepare the Area**: Lay down newspaper or a protective sheet to prevent any ink spills on your work surface.

3. **Open the Ink Pad**: Remove the ink pad from its casing if possible. Some ink pads have a removable top, while others may require you to work with the pad in its case.

4. **Apply the Ink**: Hold the refill ink bottle above the ink pad. Gently squeeze the bottle to release a few drops of ink onto the pad. Start with a small amount to avoid over-saturating.

5. **Spread the Ink**: Use a plastic spatula or an old credit card to spread the ink evenly across the surface of the pad. This ensures uniform coverage and prevents pooling.

6. **Test the Ink Pad**: Press a stamp onto the ink pad and then onto a piece of paper to test the ink distribution. If the impression is too light, add more ink gradually.

7. **Allow to Absorb**: Let the ink pad sit for a few minutes to allow the ink to absorb fully into the pad.

8. **Clean Up**: Wipe any excess ink from the edges of the pad or the work surface. Replace the ink pad in its casing if removed.

9. **Store Properly**: Close the ink pad tightly to prevent drying out and store it in a cool, dry place.

Repeat the process as needed, ensuring not to overfill, which can lead to ink leakage and mess.

What types of ink are used in ink pads?

Ink pads use several types of ink, each suited for different applications and surfaces:

1. **Dye-Based Ink**: This is the most common type of ink used in ink pads. It is water-based, dries quickly, and is suitable for porous surfaces like paper. Dye-based inks are vibrant and come in a wide range of colors, but they may fade over time and are not waterproof.

2. **Pigment Ink**: Pigment inks are thicker and more opaque than dye-based inks. They sit on top of the paper rather than soaking in, which makes them suitable for non-porous surfaces like glossy paper and vellum. Pigment inks take longer to dry but are fade-resistant and often used for archival purposes.

3. **Solvent-Based Ink**: These inks are designed for non-porous surfaces such as metal, glass, and plastic. Solvent-based inks are permanent and waterproof, making them ideal for industrial applications. They require special cleaning solutions for stamp maintenance.

4. **Hybrid Ink**: Combining the properties of dye and pigment inks, hybrid inks offer quick drying times and vibrant colors while being suitable for a variety of surfaces. They are versatile and often used in crafting.

5. **Chalk Ink**: Chalk inks provide a matte, chalk-like finish and are popular for creating a vintage or rustic look. They are suitable for both porous and non-porous surfaces and are often used in scrapbooking and card making.

6. **Embossing Ink**: This type of ink is sticky and slow-drying, designed to hold embossing powders in place until they are heat-set. Embossing inks are typically clear or lightly tinted.

7. **Fabric Ink**: Specifically formulated for stamping on textiles, fabric inks are permanent once heat-set and are used for customizing clothing and other fabric items.

Each type of ink offers unique properties, making them suitable for specific tasks and materials.

How long do ink pads last before needing a refill?

The longevity of ink pads before requiring a refill depends on several factors, including the type of ink pad, frequency of use, storage conditions, and the type of ink used. Generally, ink pads can last anywhere from a few months to several years.

1. **Type of Ink Pad**: Different types of ink pads, such as dye-based, pigment-based, or solvent-based, have varying lifespans. Dye-based ink pads tend to dry out faster than pigment-based ones, which are thicker and more resistant to drying.

2. **Frequency of Use**: The more frequently an ink pad is used, the quicker it will run out of ink. Regular use can deplete the ink within a few months, while occasional use might extend its life to a year or more.

3. **Storage Conditions**: Proper storage can significantly extend the life of an ink pad. Keeping the pad in a cool, dry place and ensuring the lid is tightly closed when not in use can prevent the ink from drying out prematurely.

4. **Type of Ink**: Some inks are more volatile and evaporate faster than others. Fast-drying inks, for example, may require more frequent refills compared to slower-drying inks.

5. **Quality of the Ink Pad**: Higher-quality ink pads often have better ink retention and distribution, which can prolong their usability.

In summary, while there is no fixed duration for how long an ink pad will last, considering these factors can help estimate its lifespan. Regular users might need to refill every few months, whereas occasional users might find their ink pads lasting a year or more. Always monitor the ink pad's performance, and refill when the impressions start to fade or become inconsistent.

Can ink pads be used on all types of paper?

Ink pads can be used on a variety of paper types, but their effectiveness and the final result can vary depending on the paper's characteristics.

1. **Absorbency**: Highly absorbent papers, like newsprint or tissue paper, can cause the ink to spread or bleed, leading to less defined images. Conversely, non-absorbent papers, such as glossy or coated papers, may not absorb the ink well, causing smudging or slow drying times.

2. **Texture**: Smooth papers, like cardstock or printer paper, generally provide a clean and crisp stamp impression. Textured papers, such as watercolor paper or handmade paper, may result in uneven ink distribution due to their surface irregularities.

3. **Weight**: Heavier papers, like cardstock, can handle more ink without warping or buckling, making them ideal for stamping. Lighter papers may not support heavy ink application and can become distorted.

4. **Color**: The color of the paper can affect the visibility of the ink. Dark papers may require opaque or metallic inks to stand out, while lighter papers work well with most ink colors.

5. **Purpose**: For archival purposes, such as scrapbooking, using acid-free and lignin-free paper is recommended to prevent deterioration over time.

6. **Ink Type**: Different inks (dye-based, pigment-based, solvent-based) interact differently with paper types. Dye-based inks dry quickly and work well on absorbent papers, while pigment-based inks are better for non-absorbent surfaces due to their opacity and slower drying time.

In summary, while ink pads can be used on most paper types, the choice of paper should align with the desired outcome, considering factors like absorbency, texture, weight, and color. Testing on a small area is advisable to ensure satisfactory results.

How do you clean an ink stamp?

To clean an ink stamp, follow these steps:

1. **Immediate Cleaning**: After use, immediately clean the stamp to prevent ink from drying. Gently press the stamp onto a damp paper towel or a wet wipe to remove excess ink.

2. **Soap and Water**: For water-based inks, use mild soap and lukewarm water. Submerge the stamp briefly and use a soft toothbrush or cloth to gently scrub the surface. Avoid soaking wooden mounts to prevent warping.

3. **Stamp Cleaner**: For stubborn or permanent inks, use a commercial stamp cleaner. Apply the cleaner to a soft cloth or directly onto the stamp, then wipe away the ink. Follow the manufacturer's instructions for best results.

4. **Rinse and Dry**: Rinse the stamp under running water to remove any soap or cleaner residue. Shake off excess water and pat dry with a clean towel. Ensure the stamp is completely dry before storing to prevent mold or damage.

5. **Conditioning**: Occasionally, condition rubber stamps with a rubber conditioner to keep them supple and extend their lifespan. Apply a small amount and wipe off any excess.

6. **Storage**: Store stamps in a cool, dry place away from direct sunlight. Keep them in a container or drawer to protect them from dust and damage.

7. **Regular Maintenance**: Regularly inspect and clean your stamps to maintain their quality. Avoid using harsh chemicals or abrasive materials that can damage the stamp surface.

By following these steps, you can effectively clean and maintain your ink stamps, ensuring they remain in good condition for future use.

What is the difference between dye-based and pigment-based ink pads?

Dye-based and pigment-based ink pads differ primarily in composition, application, and longevity.

Dye-based inks are water-soluble and made from colorants dissolved in a liquid. They are absorbed quickly into paper, resulting in fast drying times. This makes them ideal for stamping on porous surfaces like paper and cardstock. Dye inks tend to be vibrant and translucent, allowing for blending and layering of colors. However, they are not waterproof and can fade over time, especially when exposed to light.

Pigment-based inks, on the other hand, consist of tiny particles of color suspended in a binder. They sit on the surface of the paper rather than being absorbed, which results in a slower drying time. This characteristic makes them suitable for heat embossing and stamping on non-porous surfaces like vellum or glossy paper. Pigment inks are generally more opaque and offer richer, more vibrant colors. They are also more resistant to fading and are often waterproof once dry, making them ideal for archival projects.

In summary, dye-based inks are best for quick-drying, vibrant applications on porous surfaces, while pigment-based inks are preferred for their opacity, longevity, and versatility on various surfaces.

Are there eco-friendly options for ink pads and stamps?

Yes, there are eco-friendly options for ink pads and stamps. Many companies now offer products made from sustainable materials and non-toxic ingredients to reduce environmental impact.

1. **Recycled Materials**: Some ink pads are made from recycled plastics or other materials, reducing the need for new resources. Stamps can also be crafted from recycled rubber or wood.

2. **Non-Toxic Inks**: Eco-friendly ink pads often use water-based or vegetable-based inks, which are less harmful to the environment compared to traditional solvent-based inks. These inks are biodegradable and free from volatile organic compounds (VOCs).

3. **Refillable Ink Pads**: Instead of disposing of ink pads once they dry out, some brands offer refillable options. This reduces waste and extends the life of the product.

4. **Sustainable Wood**: Stamps made from sustainably sourced wood, such as FSC-certified wood, ensure that the materials are harvested responsibly, supporting forest conservation.

5. **Biodegradable Options**: Some companies produce biodegradable stamps and ink pads, which break down more easily in the environment, reducing landfill waste.

6. **Vegan and Cruelty-Free**: Eco-friendly ink pads may also be vegan and cruelty-free, ensuring no animal products are used and no animal testing is involved in their production.

7. **Local Production**: Purchasing from local manufacturers can reduce the carbon footprint associated with transportation and support local economies.

By choosing these eco-friendly options, consumers can contribute to a more sustainable environment while still enjoying the functionality of ink pads and stamps.

How do you store ink pads to prevent them from drying out?

To prevent ink pads from drying out, store them in an airtight container to minimize exposure to air. Keep them in a cool, dark place away from direct sunlight and heat sources, as these can accelerate drying. Store the ink pads upside down to ensure the ink remains at the surface, ready for use. If the ink pad has a lid, ensure it is tightly closed after each use. For added protection, consider placing a small piece of plastic wrap or wax paper between the pad and the lid before sealing. Regularly check the ink pads for dryness and re-ink them as needed with the appropriate ink refill.

Can you customize ink stamps with specific designs or logos?

Yes, you can customize ink stamps with specific designs or logos. Custom ink stamps are widely used for both personal and business purposes, allowing individuals and companies to imprint their unique designs, logos, or text onto various surfaces. The customization process typically involves the following steps:

1. **Design Creation**: You can create your design or logo using graphic design software or hire a professional designer. The design should be clear and suitable for stamping, considering the size and detail limitations of the stamp.

2. **Choosing the Stamp Type**: There are different types of stamps available, such as self-inking, pre-inked, and traditional rubber stamps. Each type has its own advantages, such as ease of use, longevity, and the ability to use different ink colors.

3. **Selecting the Size and Shape**: Stamps come in various sizes and shapes, including round, rectangular, and square. The choice depends on the design and the intended use of the stamp.

4. **Material Selection**: The stamp can be made from different materials, such as rubber, polymer, or metal, each offering different levels of durability and detail.

5. **Ordering from a Manufacturer**: Once the design is finalized, you can order the custom stamp from a manufacturer or a specialized stamp-making company. Many companies offer online platforms where you can upload your design and choose your preferences.

6. **Proof and Approval**: Before production, you may receive a digital proof of the stamp design to approve. This step ensures that the final product meets your expectations.

Custom ink stamps are versatile tools used for branding, office work, crafting, and more, providing a convenient way to replicate designs consistently.