.....Read More

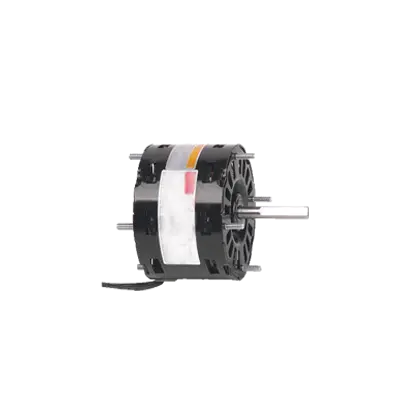

3.3 Inch Diameter HVAC AC Motors

4.4 Inch Diameter HVAC AC Motors

Belt Drive HVAC AC Motors

C-Frame HVAC AC Motors

Condenser Fan AC Motors

Direct Drive Blower HVAC AC Motors

Draft Booster AC Motors

Evaporative Cooler AC Motors

OEM Replacement AC Motors

Oil Burner AC Motors

Pedestal Fan AC Motors

Room Air Conditioner AC Motors

Unit Bearing HVAC AC Motors

Unit Heater AC Motors

Frequently Asked Questions

What is the difference between direct drive and belt drive HVAC AC motors?

How do I choose the right HVAC AC motor for my equipment?

What are the common signs of a failing HVAC AC motor?

How do I maintain and extend the life of my HVAC AC motor?

What are the energy efficiency considerations for HVAC AC motors?

How do I troubleshoot common issues with HVAC AC motors?

What are the benefits of using variable speed HVAC AC motors?