To maintain a forklift for optimal performance, follow these key steps:

1. **Regular Inspections**: Conduct daily pre-operation checks, including brakes, steering, controls, warning devices, and tires. Look for leaks, cracks, or any visible damage.

2. **Fluid Levels**: Regularly check and top off essential fluids such as hydraulic oil, engine oil, coolant, and brake fluid. Ensure they are at the recommended levels to prevent overheating and mechanical failure.

3. **Battery Maintenance**: For electric forklifts, inspect the battery for corrosion, ensure proper water levels, and charge it according to the manufacturer's guidelines. For internal combustion forklifts, check the battery terminals and connections.

4. **Tire Care**: Inspect tires for wear and tear, proper inflation, and alignment. Replace tires that show significant wear to ensure stability and safety.

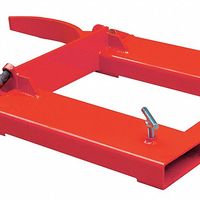

5. **Forks and Mast**: Check forks for cracks, bends, and wear. Ensure the mast is lubricated and free of obstructions. Adjust and tighten any loose bolts or pins.

6. **Lubrication**: Regularly lubricate all moving parts, including chains, joints, and bearings, to reduce friction and wear.

7. **Brake System**: Test the brakes daily for responsiveness. Replace worn-out brake pads and check the brake fluid levels.

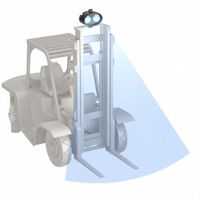

8. **Safety Features**: Ensure all safety features, such as seat belts, lights, horns, and alarms, are functioning correctly.

9. **Cleanliness**: Keep the forklift clean to prevent dust and debris from affecting performance. Regularly clean the radiator and air filters.

10. **Professional Servicing**: Schedule regular maintenance with a certified technician to perform in-depth inspections and repairs.

11. **Operator Training**: Ensure operators are trained in proper forklift use and maintenance procedures to prevent misuse and damage.

By adhering to these maintenance practices, you can enhance the longevity and efficiency of your forklift, ensuring safe and reliable operation.