- Home

- Material Handling

- Storage Workspace

- Storage Containers

- Totes Storage Boxes Trunks

.....Read More

Attached-Lid Totes

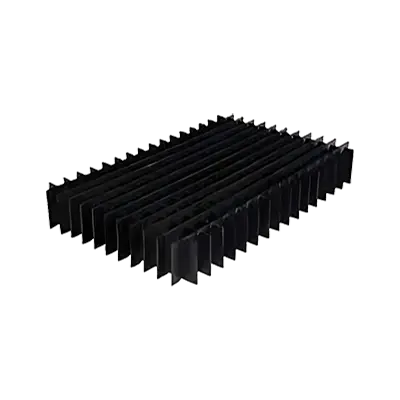

ESD Static-Control Divider Box Dividers

ESD Static-Control Storage & Divider Box Covers & Lids

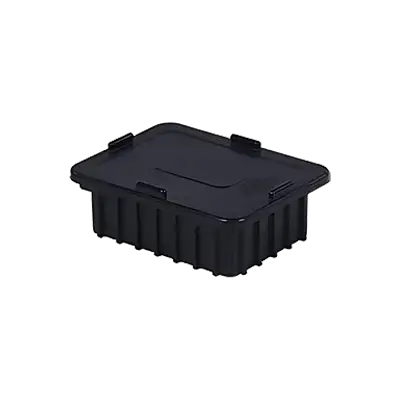

ESD Static-Control Storage & Divider Boxes

High-Temperature Process Tote Lids

High-Temperature Process Totes & Tubs

Stacking & Nesting Tote Lids

Stacking & Nesting Totes

Standard Divider Boxes & Accessories

Storage Trunks

Straight Wall Container Lids & Cups

Straight-Wall Containers

Totes with Snap-On Lids

Frequently Asked Questions

What are the best materials for storage totes and boxes?

How do I choose the right size storage container?

What are the benefits of using totes with snap-on lids?

How do stacking and nesting totes save space?

What is the difference between attached-lid totes and open-top totes?

How do ESD static-control storage boxes work?

What are high-temperature process totes used for?