Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Storage Workspace

- Storage Containers

- Protective Equipment Cases

.....Read More

Frequently Asked Questions

What are protective equipment cases used for?

Protective equipment cases are used to safeguard sensitive, valuable, or fragile items from damage during storage or transport. These cases are designed to provide a robust barrier against environmental factors such as moisture, dust, and extreme temperatures, ensuring the contents remain intact and functional. They are commonly used in various industries, including military, law enforcement, photography, medical, and electronics, to protect equipment like cameras, firearms, medical instruments, and electronic devices.

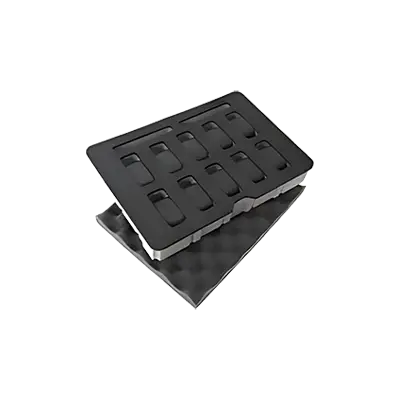

The cases are typically constructed from durable materials such as high-impact plastic, aluminum, or composite materials, offering resistance to impact, corrosion, and wear. Many protective cases are also equipped with foam inserts that can be customized to fit the specific shape of the items being stored, providing additional cushioning and preventing movement within the case.

In addition to physical protection, these cases often feature secure locking mechanisms to prevent unauthorized access, making them ideal for transporting sensitive or high-value items. Some cases are also designed to be waterproof and airtight, with pressure equalization valves to maintain internal pressure and prevent water ingress, which is crucial for items that are sensitive to moisture or pressure changes.

Overall, protective equipment cases are essential for ensuring the longevity and functionality of critical equipment, minimizing the risk of damage during transit, and providing peace of mind to users who rely on the integrity of their tools and devices.

How do protective equipment cases protect their contents?

Protective equipment cases safeguard their contents through a combination of robust design features and materials engineered to withstand various environmental and physical challenges. These cases are typically constructed from durable materials such as high-impact plastics, aluminum, or composite materials, which provide a strong barrier against physical impacts, drops, and crushing forces. The rigid structure of these materials helps absorb and distribute shock, minimizing the risk of damage to the contents.

Inside, protective cases often feature custom foam inserts or padding that cradle the items, providing additional shock absorption and preventing movement during transit. This interior cushioning is crucial for protecting delicate or sensitive equipment from vibrations and jolts.

To guard against environmental factors, protective cases are designed to be water-resistant or waterproof, often featuring airtight seals and gaskets. These seals prevent the ingress of water, dust, and other contaminants, ensuring the contents remain dry and clean even in harsh conditions. Many cases also include pressure relief valves to equalize pressure differences, which is particularly important during air travel to prevent damage from pressure changes.

Additionally, protective cases often come with secure locking mechanisms, such as latches or padlocks, to prevent unauthorized access and ensure the contents remain secure. Some cases are also equipped with features like UV resistance and corrosion resistance to withstand prolonged exposure to sunlight and harsh environments.

Overall, the combination of durable materials, shock-absorbing interiors, environmental seals, and secure locking systems work together to provide comprehensive protection for the contents, ensuring they remain intact and functional regardless of the conditions they encounter.

What types of items can be stored in protective equipment cases?

Protective equipment cases are designed to store and safeguard a wide range of items, ensuring they remain secure and undamaged during transport or storage. Common items stored in these cases include:

1. **Electronics**: Cameras, drones, laptops, tablets, and other sensitive electronic devices are often stored in protective cases to prevent damage from impact, moisture, and dust.

2. **Photography Gear**: Lenses, tripods, flashes, and other photography accessories are kept safe from physical damage and environmental factors.

3. **Tools and Instruments**: Precision tools, measuring instruments, and specialized equipment are stored to maintain their accuracy and functionality.

4. **Weapons and Ammunition**: Firearms, ammunition, and related accessories are stored securely to prevent unauthorized access and ensure safety.

5. **Medical Equipment**: Portable medical devices, first aid kits, and emergency medical supplies are protected from contamination and damage.

6. **Musical Instruments**: Guitars, violins, and other delicate instruments are stored to prevent physical damage and maintain sound quality.

7. **Scientific Equipment**: Lab instruments, samples, and sensitive scientific tools are kept safe from environmental factors and physical damage.

8. **Sports Equipment**: Items like helmets, protective pads, and other gear are stored to maintain their integrity and prolong their lifespan.

9. **Military and Tactical Gear**: Communication devices, night vision goggles, and other tactical equipment are stored to ensure readiness and functionality.

10. **Documents and Data Storage**: Important documents, hard drives, and data storage devices are protected from physical damage and unauthorized access.

11. **Art and Collectibles**: Valuable art pieces, collectibles, and antiques are stored to prevent damage and preserve their value.

These cases are typically made from durable materials like high-impact plastic, aluminum, or composite materials, often featuring foam inserts for added protection and organization.

What are the different styles of protective equipment cases?

Protective equipment cases come in various styles, each designed to cater to specific needs and environments:

1. **Hard Cases**: Made from durable materials like polypropylene or aluminum, these cases offer maximum protection against impact, water, and dust. They often feature foam inserts for custom fitting and are ideal for transporting sensitive equipment.

2. **Soft Cases**: Constructed from materials like nylon or polyester, soft cases provide lightweight protection and are often padded for shock absorption. They are suitable for less hazardous environments and offer more flexibility and storage options.

3. **Waterproof Cases**: Designed to be completely watertight, these cases are perfect for environments where equipment might be exposed to water or moisture. They often include O-ring seals and pressure equalization valves.

4. **Shockproof Cases**: These cases are engineered to withstand significant impact and vibration. They typically include reinforced corners and shock-absorbing materials, making them ideal for transporting delicate electronics or instruments.

5. **Custom Cases**: Tailored to specific equipment, custom cases are designed to fit the exact dimensions and requirements of the items they protect. They can be hard or soft and often include custom foam inserts.

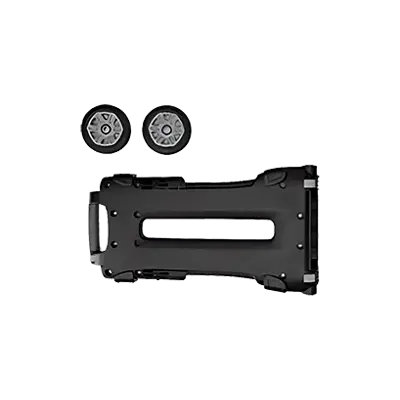

6. **Rolling Cases**: Equipped with wheels and telescopic handles, rolling cases are designed for easy transport of heavy or bulky equipment. They are often used in professional settings where mobility is crucial.

7. **Rack Cases**: These cases are designed to house rack-mounted equipment, such as audio or IT gear. They provide secure mounting and protection during transport and are often used by professionals in the music and technology industries.

8. **Military-Grade Cases**: Built to meet military specifications, these cases offer extreme durability and protection. They are used in harsh environments and for critical equipment that requires the highest level of security.

Each style serves a unique purpose, ensuring that equipment remains safe and functional in various conditions.

How do suitcase-style cases differ from transport cases?

Suitcase-style cases and transport cases differ primarily in design, purpose, and construction.

Suitcase-style cases are typically designed for personal travel and are characterized by their compact, lightweight design, often featuring wheels and a telescopic handle for easy maneuverability. They are usually made from materials like polycarbonate, ABS plastic, or fabric, providing a balance between durability and weight. These cases are intended for carrying clothing, personal items, and other travel essentials, with interior compartments and straps to organize belongings. They prioritize convenience and style, often available in various colors and designs to suit personal preferences.

Transport cases, on the other hand, are designed for industrial, commercial, or specialized use, focusing on durability and protection. They are often constructed from heavy-duty materials like aluminum, high-impact plastic, or composite materials, providing superior resistance to impact, water, dust, and extreme temperatures. These cases are used to transport sensitive equipment, tools, electronics, or hazardous materials, ensuring their safety during transit. Transport cases often feature customizable foam interiors to securely hold and protect contents, reinforced corners, and robust locking mechanisms for added security. They may also include features like pressure relief valves and stacking capabilities for efficient storage and transport.

In summary, suitcase-style cases are tailored for personal travel with an emphasis on convenience and aesthetics, while transport cases are built for rugged use, offering maximum protection for valuable or sensitive items.

What are rack-mount cases used for?

Rack-mount cases are used to house and organize electronic equipment in a standardized framework, typically within data centers, server rooms, or industrial environments. These cases are designed to fit into a 19-inch rack, which is a standardized frame or enclosure for mounting multiple equipment modules. Each module has a front panel that is 19 inches wide, and the height is measured in rack units (U), with 1U equaling 1.75 inches.

The primary purpose of rack-mount cases is to efficiently utilize space by stacking equipment vertically, allowing for better organization and accessibility. This setup facilitates easier maintenance, upgrades, and cable management. Rack-mount cases are commonly used for servers, networking equipment like switches and routers, audio and video equipment, and telecommunications hardware.

They provide several advantages, including improved cooling and ventilation, as the design often incorporates fans and airflow paths to dissipate heat generated by the equipment. This is crucial for maintaining optimal performance and longevity of the hardware. Additionally, rack-mount cases offer enhanced security, as they can be locked to prevent unauthorized access.

Moreover, these cases contribute to a cleaner and more professional appearance, reducing clutter and making it easier to identify and troubleshoot issues. They also support scalability, allowing organizations to add or remove equipment as needed without significant reconfiguration.

In summary, rack-mount cases are essential for organizing, protecting, and managing electronic equipment in environments where space efficiency, cooling, security, and scalability are critical.

What is the purpose of tube cases?

Tube cases are designed to protect and transport items that are long, cylindrical, or require a specific shape for storage. They serve several purposes:

1. **Protection**: Tube cases safeguard contents from physical damage, such as bending, crushing, or breaking. They are often made from durable materials like plastic, metal, or reinforced cardboard to provide a sturdy barrier against external forces.

2. **Portability**: These cases make it easier to carry and transport items that are awkwardly shaped or fragile. They often come with handles or straps for convenient handling.

3. **Organization**: Tube cases help keep items organized and prevent them from getting lost or mixed up with other materials. This is particularly useful for professionals who need to keep tools, documents, or equipment in order.

4. **Preservation**: By providing a sealed environment, tube cases can protect contents from environmental factors such as moisture, dust, and UV light, which can cause deterioration over time.

5. **Versatility**: They are used across various industries and for multiple purposes, including storing blueprints, artwork, fishing rods, camera equipment, and musical instruments. Their design can be customized to fit specific needs.

6. **Security**: Many tube cases come with locking mechanisms to ensure that the contents remain secure and are only accessible to authorized individuals.

7. **Aesthetic Appeal**: For items like artwork or high-end equipment, tube cases can offer a professional and polished appearance, enhancing the presentation and perceived value of the contents.

Overall, tube cases are essential for anyone needing to store, protect, and transport elongated or delicate items efficiently and safely.