- Home

- Material Handling

- Storage Workspace

- Shelving Storage Racks

- Freestanding Shelving Shelf Racks

.....Read More

Archival Boltless Metal Shelving

Beams & Crossbars for Bulk Rack Metal Shelving

Braces, Brackets & Hardware for Standard Metal Shelving

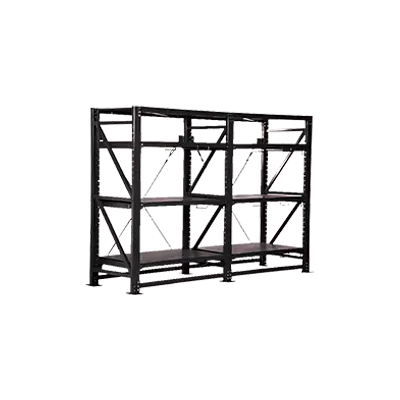

Bulk Rack Metal Shelving

Cantilever Metal Shelving

Closed Metal Shelving

Corrosion-Resistant Open Metal Shelving

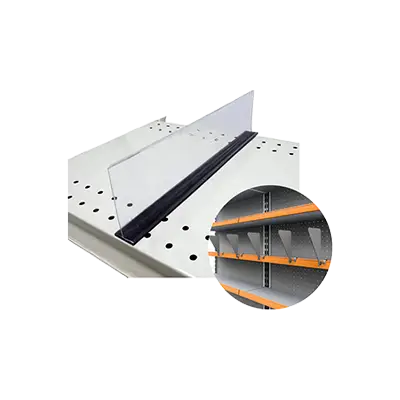

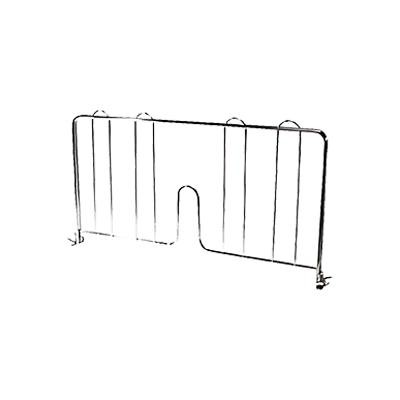

Dividers for Standard Metal Shelving

General Purpose Boltless Metal Shelving

Gravity-Flow Boltless Metal Shelving

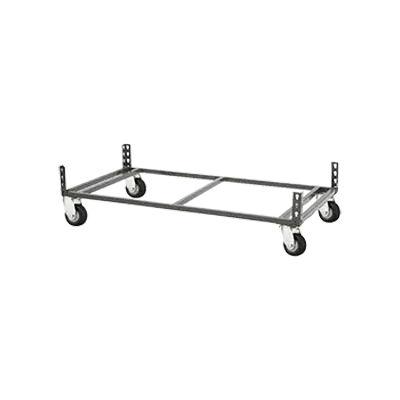

Mobile Bases & Feet for Standard Metal Shelving

Mobile Open Metal Shelving

Mobile Plastic Shelving

Mobile Wire Shelving

Open Metal Shelving

Panels, Doors & Base Strips for Standard Metal Shelving

Plastic Shelving Baskets & Trays

Plastic Shelving Casters

Plastic Shelving Dividers & Ledges

Plastic Shelving Hardware

Plastic Shelving Label Holders & Markers

Plates & Caps for Boltless Metal Shelving

Posts for Boltless Metal Shelving

Posts for Plastic Shelving

Posts for Standard Metal Shelving

Posts for Wire Shelving

Roll-Out Metal Shelving

Shelf Kits & Decking for Boltless Metal Shelving

Shelf Kits & Decking for Bulk Rack Metal Shelving

Shelves for Plastic Shelving

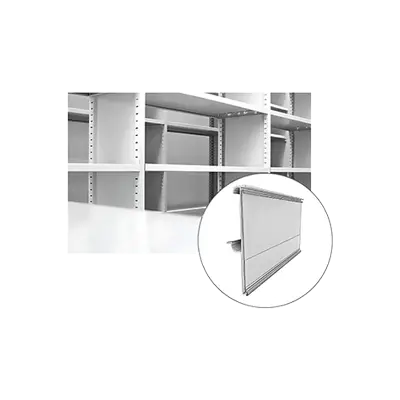

Shelves for Standard Metal Shelving

Solid & Louvered Shelves for Wire Shelving

Spill-Containment Liners for Standard Metal Shelving

Split-Post Configurable Boltless Metal Shelving

Stationary Metal Bin Shelving & Racks

Stationary Plastic Shelving

Stationary Wire Shelving

Top-Track Wire Shelving

Uprights for Bulk Rack Metal Shelving

Welded Metal Shelving

Wire Shelves for Wire Shelving

Wire Shelving Baskets, Bins & Holders

Wire Shelving Casters, Dollies & Push Handles

Wire Shelving Dividers, Ledges, Liners & Panels

Wire Shelving Hardware

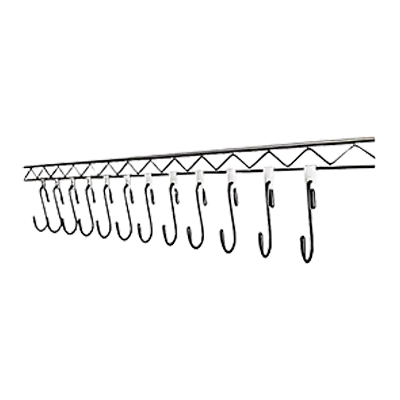

Wire Shelving Hooks & Hanger Rods

Wire Shelving Shelf Label Holders & Markers

Frequently Asked Questions

What are the benefits of freestanding shelving and shelf racks?

How do I choose the right material for shelving units?

What are the weight capacities of different shelving types?

How do I assemble freestanding shelving units?

What are the best uses for wire shelving?

How do I maintain and clean metal and plastic shelving?

What safety considerations should I keep in mind for shelving units?