- Home

- Material Handling

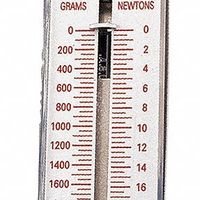

- Scales And Scale Accessories

.....Read More

Frequently Asked Questions

1. How do scales and weighing systems ensure accurate weight measurements?

2. What are the differences between medical scales and bathroom scales?

3. How do bench and floor scales differ in their applications?

4. What are the uses of crane scales and dynamometers in industrial settings?

5. How do food scales differ from lab scales in terms of precision and application?

6. What are the common accessories for scales and how do they improve accuracy?

7. How often should scales be calibrated to maintain accuracy?

8. What factors can affect the accuracy of a weighing system?

9. How do digital scales compare to analog scales in terms of reliability?

10. What maintenance is required to ensure the longevity of weighing systems?