Securing cargo on a flatbed trailer requires careful attention to detail and adherence to best practices to prevent shifting, damage, or loss during transit. Key practices include:1. **Inspect Equipment:** Before loading, thoroughly inspect the trailer, including the deck, winches, straps, chains, and binders, for any signs of damage or wear. Ensure all securing devices are in good working order.

2. **Distribute Weight Evenly:** Properly distribute the cargo's weight across the trailer's deck. This helps maintain stability and prevents undue stress on specific areas of the trailer or tires. Heavy items should generally be placed towards the front of the trailer and low to the deck.

3. **Use Adequate Tie-Downs:** The number and type of tie-downs depend on the cargo's weight, size, and shape. Always use enough tie-downs to meet or exceed the cargo's working load limit. For most cargo, a minimum of two tie-downs is recommended, with additional tie-downs every 10 feet of cargo length for long items.

4. **Employ Appropriate Securing Methods:**

* **Straps:** Use strong, weather-resistant straps for lighter loads or those susceptible to damage from chains. Ensure straps are not twisted and are protected from sharp edges.

* **Chains:** For heavy or irregular loads, chains are often preferred. Use appropriate chain grades and binders.

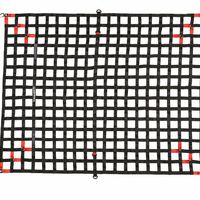

* **Blocking and Bracing:** Use dunnage, blocks, and bracing to prevent cargo from sliding forward, backward, or sideways. This is particularly important for irregular or unstable loads.

* **Friction Mats:** Place friction mats under the cargo to increase grip and reduce the likelihood of movement.

5. **Secure All Loose Items:** Any loose equipment, tools, or accessories on the trailer should be secured to prevent them from falling off or becoming projectiles.

6. **Regularly Check Tie-Downs:** During transit, especially after the first few miles and at regular intervals (e.g., every 50-100 miles or at every stop), re-check the tension of all tie-downs. Cargo can settle, causing straps and chains to loosen.

7. **Comply with Regulations:** Be aware of and comply with all federal, state, and local regulations regarding cargo securement. These regulations often specify minimum tie-down requirements and safe operating procedures.By following these best practices, you can significantly reduce the risk of incidents and ensure the safe transport of cargo on flatbed trailers.