Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Dock Loading Equipment

.....Read More

Frequently Asked Questions

What are the essential types of dock equipment for loading and unloading goods?

Essential dock equipment for loading and unloading goods includes a variety of tools designed to enhance efficiency, safety, and productivity. Dock levelers are crucial for bridging the gap and height difference between the warehouse floor and the truck bed, allowing forklifts and pallet jacks to move smoothly. Different types exist, such as hydraulic, mechanical, and air-powered, each offering varying levels of convenience and cost.

Vehicle restraints are vital for safety, securing the truck to the loading dock to prevent unexpected movement during loading or unloading, which can lead to serious accidents. These can be manual or automatic. Dock seals and shelters are used to create a tight seal between the building and the trailer, protecting goods from outdoor elements, maintaining temperature control, and improving energy efficiency.

Forklifts and pallet jacks are fundamental for material handling, used to lift, move, and stack goods. Forklifts are motorized for heavier loads and longer distances, while pallet jacks are manual or electric and suited for shorter moves and lighter loads. Other important equipment includes dock lights for improved visibility during low-light conditions, wheel chocks for additional safety, and dock bumpers to protect the building and vehicles from impact damage. Each piece of equipment plays a specific role in ensuring a smooth and safe loading and unloading operation.

How do wheel chocks prevent vehicle movement during loading?

Wheel chocks prevent vehicle movement during loading by being placed snugly against the wheels of a vehicle, typically on both sides of a tire. Their wedge shape creates a barrier that resists the force of gravity or any accidental nudges, effectively immobilizing the vehicle. This is crucial during loading and unloading operations to prevent unexpected rolling, which could lead to serious accidents, damage to property, or injury to personnel. The friction between the chock and the ground, as well as the chock and the tire, further enhances their effectiveness in holding the vehicle securely in place. Different types of chocks are designed for various vehicle sizes and ground surfaces to maximize their gripping power and ensure stability.

What is the purpose of trailer-stabilizing jacks in loading docks?

Trailer-stabilizing jacks are crucial safety devices used in loading dock operations. Their primary purpose is to prevent accidents and injuries caused by trailer tip-overs or "trailer up-ending" during loading and unloading. When a forklift enters a trailer, especially towards the front, the weight can cause the trailer to tilt forward, lifting the rear of the trailer off its landing gear. This can result in serious damage to equipment, products, and most importantly, personnel. Stabilizing jacks are placed under the front of the trailer to provide additional support and prevent this dangerous tilting. They essentially create a more stable and level surface for the forklifts to operate on, ensuring the trailer remains securely in place throughout the loading and unloading process. This enhanced stability significantly reduces the risk of accidents, protects workers, and ensures the efficiency of dock operations.

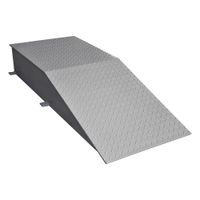

How do loading ramps, plates, and boards facilitate transitions between trucks and docks?

Loading ramps, plates, and boards are essential tools for safely and efficiently bridging the gap between a truck and a loading dock. They facilitate transitions by creating a stable and gradual incline or level surface for material handling equipment, such as forklifts, pallet jacks, or hand trucks, to move between different heights.

Ramps typically offer a longer, more gradual slope, making them suitable for heavier loads and powered equipment. They are designed to accommodate varying truck bed heights and dock levels, ensuring a smooth and controlled ascent or descent.

Dock plates are generally smaller and lighter, providing a simple bridge for lighter, non-powered equipment and pedestrian traffic over a short gap. They are often used for quick transitions where minor height differences exist.

Dock boards are heavier and more robust than plates, designed to handle heavier loads and power equipment. They usually feature safety curbs or side rails to prevent equipment from rolling off the edge and are capable of spanning larger gaps and greater height differentials.

All three tools aim to reduce the risk of accidents, injuries, and product damage by eliminating hazardous gaps and uneven surfaces, thereby streamlining the loading and unloading process.

Why are dock bumpers important for protecting buildings?

Dock bumpers are crucial for protecting buildings, especially in areas with high traffic like loading docks. They act as a buffer between vehicles, such as trucks and forklifts, and the building structure. Without them, vehicles can directly impact walls, foundations, and support columns, leading to significant structural damage over time. This damage can include cracks in masonry, weakened foundations, and compromised structural integrity, which can be costly to repair and potentially unsafe.

Beyond structural protection, dock bumpers also help preserve the aesthetic and functional aspects of a building. They prevent dents, scrapes, and other surface damage to the exterior, maintaining a professional appearance. They also absorb the impact, reducing wear and tear on the building's loading dock equipment, such as doors and seals, extending their lifespan and reducing maintenance costs. In essence, dock bumpers are a relatively inexpensive yet highly effective preventative measure that safeguards the long-term integrity, safety, and operational efficiency of a building.

How do dock seals and shelters contribute to safety and cleanliness?

Dock seals and shelters are crucial for maintaining safety and cleanliness in loading dock areas by providing a secure and environmentally controlled connection between the building and the trailer.

Regarding safety, they prevent accidents by bridging the gap between the dock and the trailer, reducing trip hazards for personnel and preventing equipment from falling. By sealing off the opening, they also protect workers from extreme weather conditions, such as rain, snow, and wind, which can make the dock surface slippery and dangerous. Furthermore, a sealed environment can reduce the entry of pests and airborne contaminants, contributing to a healthier and safer working environment.

In terms of cleanliness, dock seals and shelters create a barrier against dust, debris, and insects from entering the facility during loading and unloading operations. This is particularly important for industries with strict hygiene requirements, such as food processing or pharmaceuticals. By minimizing the ingress of external elements, they help maintain a clean and sterile indoor environment, reducing the need for extensive cleaning and preventing potential contamination of products or equipment. They also help in maintaining consistent indoor temperatures, which can prevent condensation and moisture buildup that could lead to mold or mildew growth, further contributing to overall cleanliness.

What role do dock doors, curtains, and openers play in loading dock security?

Dock doors, curtains, and openers are crucial for loading dock security by controlling access and protecting assets. Dock doors, often overhead or sectional, provide a physical barrier against unauthorized entry and theft when closed. They also protect goods from weather, reducing potential damage or spoilage. Curtains, or dock seals/shelters, create a tight seal between the building and the trailer, preventing pests, dust, and extreme temperatures from entering, which can deter opportunistic theft and maintain product integrity. Automated openers enhance security by allowing controlled and efficient access. They can be integrated with access control systems, requiring authorized personnel to operate them, and often have features like automatic locking or alarms. Together, these components create a robust security system, deterring unauthorized access, protecting inventory, and improving overall operational safety on the loading dock.

How do dock gates enhance safety in industrial facilities?

Dock gates significantly enhance safety in industrial facilities by creating a physical barrier that prevents falls from elevated loading docks, especially during loading and unloading operations. They act as a critical control point, ensuring that personnel and equipment do not accidentally drive or walk off the edge of the dock.

Furthermore, dock gates help to manage traffic flow and delineate safe work zones. By clearly defining the boundaries of the loading area, they reduce the risk of collisions between forklifts, trucks, and pedestrians. This is particularly important in busy industrial environments where multiple activities are occurring simultaneously. Some advanced dock gates also incorporate interlocks that prevent truck movement until the gate is closed, adding another layer of protection. This prevents "premature drive-offs" that can lead to serious injuries or fatalities. In essence, dock gates minimize human error, improve situational awareness, and provide a robust physical safeguard against common industrial accidents.

What is the function of dock door safety nets?

Dock door safety nets are crucial for preventing accidents and injuries at loading docks. Their primary function is to provide a physical barrier that stops personnel, equipment, or products from falling off the edge of the dock when a truck is not present. This is especially important when dock doors are open for ventilation or maintenance, as an open dock door can pose a significant fall hazard. The nets are designed to be durable and withstand significant impact, absorbing the force of a fall and preventing serious harm or damage. They help maintain a safe working environment by reducing the risk of costly accidents and ensuring compliance with safety regulations.

How do wheel risers assist in aligning trucks with loading docks?

Wheel risers play a crucial role in aligning trucks with loading docks by elevating the rear of a truck or trailer to match the height of the dock. This is particularly important when there's a height difference between the truck's bed and the loading dock, which can occur due to various factors like truck suspension, tire size, or the type of trailer being used. By raising the truck to an optimal height, wheel risers create a level transition between the truck bed and the dock, facilitating safer and more efficient loading and unloading operations. This eliminates steep inclines or declines that can cause equipment damage, product shifting, or even injuries to personnel. They also help in maintaining proper alignment during the entire process, preventing the truck from shifting or becoming misaligned, which can lead to gaps or uneven surfaces. Ultimately, wheel risers contribute to improved safety, reduced product damage, and increased productivity at loading docks.