Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Lubrication

- Grease

.....Read More

Frequently Asked Questions

What is the difference between grease and oil lubricants?

Oil and grease are both lubricants, but they differ significantly in their composition and application. Oil is a liquid lubricant consisting of a base oil and additives, designed to reduce friction and wear between moving parts. It flows easily, allowing it to penetrate tight spaces and dissipate heat efficiently. Oil is typically used in systems requiring constant circulation, such as engines, gearboxes, and hydraulic systems, where it can be pumped and filtered.

Grease, on the other hand, is a semi-solid lubricant. It's made by combining a base oil with a thickening agent (like metallic soap) and various additives. This structure gives grease its higher viscosity and ability to stay in place. Grease is ideal for applications where oil leakage is a concern, where frequent re-lubrication is impractical, or where parts are exposed to harsh environments, such as bearings, open gears, and chassis components. While oil excels at heat dissipation and continuous lubrication, grease provides a more stable, long-lasting film and better sealing properties in less accessible or intermittently operated machinery.

How do I choose the right grease for my equipment?

Choosing the right grease for your equipment involves considering several critical factors to ensure optimal performance and longevity.

First, assess the operating conditions. This includes the temperature range the equipment will be exposed to (high temperatures require greases with excellent thermal stability, while low temperatures demand good flow characteristics). The speed and load of the application are also crucial; high-speed applications often benefit from lower viscosity greases, while high loads require greases with robust film strength and extreme pressure (EP) additives.

Second, consider the environment. If the equipment is exposed to water or contaminants, a grease with good water resistance and sealing properties is essential. Corrosive environments may necessitate greases with corrosion inhibitors.

Third, understand the type of bearing or component. Different types of bearings (e.g., ball bearings, roller bearings, plain bearings) have varying lubrication needs. The materials of construction of the components also play a role, as some greases can be incompatible with certain seals or plastics.

Finally, always refer to the equipment manufacturer's recommendations. They often specify the type of grease required, which is the safest and most effective starting point. If no specific recommendation is given, consider consulting with a lubricant supplier or an lubrication expert who can help you select the most suitable grease based on a detailed analysis of your application.

What are the benefits of using multipurpose grease?

Using multipurpose grease offers several key benefits in various applications. Firstly, it provides excellent lubrication, reducing friction and wear between moving parts. This extends the lifespan of machinery and components, leading to fewer breakdowns and lower replacement costs. Secondly, its water resistance properties are crucial in environments exposed to moisture, preventing rust and corrosion, which can severely damage equipment. Thirdly, multipurpose grease often contains additives that enhance its performance, such as extreme pressure (EP) additives that protect components under heavy loads, and anti-oxidants that prevent grease degradation over time. Finally, the "multipurpose" aspect itself is a significant advantage, as it simplifies inventory and maintenance. Instead of stocking different types of grease for various applications, a single multipurpose grease can often meet the needs of many components, streamlining operations and reducing the risk of using the wrong lubricant. This versatility makes it a cost-effective and efficient choice for a wide range of industrial, automotive, and household applications.

How often should I apply grease to machinery?

The frequency of applying grease to machinery depends on several factors, including the type of machinery, its operating conditions, the type of grease used, and the manufacturer's recommendations.

Generally, for machinery under normal operating conditions, greasing can range from daily to monthly or even quarterly. High-speed, high-temperature, or heavily loaded machinery will require more frequent lubrication. Conversely, machinery operating in clean, low-stress environments may need less frequent greasing.

It's crucial to consult the equipment manufacturer's manual for specific greasing schedules and recommended grease types. Over-greasing can be as detrimental as under-greasing, leading to excessive heat, seal damage, and wasted lubricant. Modern lubrication systems, such as automatic greasers, can help optimize greasing frequency and prevent these issues. Regular inspections for signs of wear or inadequate lubrication are also essential.

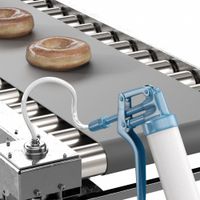

What is food-grade grease and where is it used?

Food-grade grease, also known as H1 lubricant, is a specialized type of lubricant formulated to be safe for incidental contact with food products. It is made from non-toxic ingredients and does not contain harmful chemicals that could contaminate food. This makes it crucial for applications in the food and beverage industry, where machinery and equipment come into close proximity with food.

Food-grade grease is widely used in various stages of food processing, packaging, and handling. Common applications include: * **Food Processing Equipment:** Lubricating gears, bearings, and other moving parts in mixers, ovens, conveyors, slicers, and other machinery used in food production.

* **Packaging Machinery:** Ensuring smooth operation of equipment involved in bottling, canning, and packaging food products.

* **Bakeries and Dairies:** Used in equipment for baking, mixing dough, and processing dairy products.

* **Pharmaceutical and Cosmetic Industries:** While not food, these industries also require high purity lubricants for similar reasons of product integrity.The primary purpose of food-grade grease is to reduce friction and wear, extend the lifespan of equipment, and prevent breakdowns, all while adhering to strict safety and hygiene standards in food production environments.

How does bearing grease improve the performance of bearings?

Bearing grease improves the performance of bearings in several key ways, primarily by reducing friction, preventing wear, and protecting against contamination and corrosion.

Firstly, grease provides a lubricating film between the moving parts of the bearing, such as the rolling elements and raceways. This film separates the surfaces, significantly reducing direct metal-to-metal contact and, consequently, friction. Lower friction leads to less heat generation, which extends the life of the bearing and improves energy efficiency.

Secondly, the lubricating film formed by the grease minimizes wear on the bearing components. Without proper lubrication, the constant contact and sliding between surfaces would lead to abrasive and adhesive wear, causing material loss and eventual bearing failure. Grease creates a protective barrier that absorbs some of the operational stresses, preserving the integrity of the bearing surfaces.

Thirdly, bearing grease acts as a seal, preventing the ingress of contaminants like dust, dirt, moisture, and other foreign particles into the bearing. These contaminants can cause significant damage, leading to premature wear and failure. The viscous nature of grease helps to form a barrier that seals the bearing from its external environment.

Lastly, many greases contain additives that provide corrosion protection. Bearings can be exposed to moisture and corrosive substances, which can lead to rust and other forms of degradation. Anti-corrosion additives in grease create a protective layer that inhibits these chemical reactions, safeguarding the metal surfaces of the bearing.

In summary, bearing grease is crucial for optimal bearing performance, contributing to reduced friction, extended lifespan, enhanced protection against contaminants, and corrosion resistance, all of which are vital for efficient and reliable machinery operation.

What is the purpose of O-ring grease?

O-ring grease, also known as O-ring lubricant or sealant, serves several critical purposes in maintaining the integrity and performance of O-ring seals. Its primary function is to reduce friction during installation, making it easier to seat the O-ring without damaging it. This lubrication also helps prevent twisting, stretching, or pinching of the O-ring, which can lead to leaks.

Beyond installation, O-ring grease provides ongoing lubrication during operation, which can extend the lifespan of the O-ring by reducing wear and tear. It can also help to prevent the O-ring from drying out or sticking to the mating surfaces, especially in applications with infrequent movement.

Furthermore, some O-ring greases are formulated with properties that enhance the sealing capability. They can fill microscopic imperfections on the mating surfaces, creating a more complete seal and preventing fluid or gas bypass. This is particularly important in high-pressure or vacuum applications.

Finally, the choice of O-ring grease is crucial and depends on the specific application, including the type of O-ring material, the fluids or gases being sealed, temperature ranges, and pressure conditions. Using an incompatible grease can cause the O-ring to swell, shrink, or degrade, leading to seal failure.

How do I apply grease to open gears?

Applying grease to open gears effectively requires a methodical approach to ensure proper lubrication and extend the lifespan of the gears. First, ensure the gears are clean and free of old grease, dirt, and debris. You can use a solvent-based cleaner and brushes to remove stubborn residue. Once clean, allow the gears to dry completely.

Next, select the appropriate grease for your open gears. This typically involves considering factors like the operating temperature, load, and environment. For instance, heavy-duty, high-viscosity greases are often preferred for heavily loaded gears, while greases with good water resistance are crucial in wet conditions. Many open gear greases contain solid lubricants like graphite or molybdenum disulfide to enhance their load-carrying capacity and reduce wear.

The application method itself can vary. For smaller, slower-moving gears, manual application with a brush or spatula can be effective, ensuring an even coating on the teeth. For larger or more critical applications, automated systems like spray applicators are common. These systems provide a consistent and controlled application, minimizing waste and ensuring thorough coverage. When applying, focus on the meshing surfaces of the gear teeth. The goal is to create a durable lubricating film that can withstand the high pressures and sliding action between the gear teeth. Avoid over-application, as excessive grease can attract more contaminants and lead to inefficiencies. Regular inspection and re-application, based on the manufacturer's recommendations and operating conditions, are key to maintaining optimal lubrication.

What are the signs that grease needs to be reapplied?

The signs that grease needs to be reapplied include: * **Audible changes:** Increased noise (squealing, grinding, clunking) from the lubricated component often indicates a lack of proper lubrication and increased friction.

* **Temperature increases:** Excess friction due to insufficient grease can lead to a rise in operating temperature, which can be detected by touch or with temperature sensors.

* **Visible wear:** Accelerated wear on components, such as scoring or pitting, suggests that the protective film of grease is no longer adequate.

* **Grease degradation:** The existing grease may show signs of breakdown, such as becoming discolored, hardened, or watery, indicating it has lost its lubricating properties.

* **Leakage:** If grease is leaking excessively from a seal, it can indicate that the component is losing its lubrication, or that the wrong type or amount of grease is being used.

* **Reduced performance:** Equipment may operate less efficiently, require more power, or experience decreased accuracy if components are not adequately lubricated.

* **Vibration:** Increased vibration can be a symptom of metal-on-metal contact due to insufficient lubrication.Regular inspection and a proactive maintenance schedule, based on the manufacturer's recommendations and operating conditions, are essential to prevent issues caused by insufficient greasing.

Can different types of grease be mixed together?

Generally, it is not recommended to mix different types of grease. Greases are formulated with specific base oils, thickeners, and additives that are designed to work together to provide optimal lubrication and protection under certain operating conditions. Mixing greases can lead to several problems:1. **Incompatibility:** Different thickeners and additives may not be compatible, leading to a breakdown of the grease structure. This can result in softening or hardening of the grease, reduced film strength, and decreased lubrication effectiveness.

2. **Reduced Performance:** The performance properties of the individual greases can be compromised when mixed. This can lead to increased friction, wear, and premature equipment failure.

3. **Shortened Lubricant Life:** Incompatible mixtures can degrade more quickly, reducing the overall lifespan of the lubricant and requiring more frequent re-lubrication.

4. **Additive Antagonism:** Some additives may counteract the beneficial effects of others when mixed, leading to a reduction in protective properties like rust inhibition or extreme pressure resistance.If you must switch grease types, it's best to thoroughly clean out the old grease from the system to prevent contamination. If cleaning is not feasible, consult the grease manufacturer's compatibility chart or a lubrication expert to determine if the specific greases can be safely mixed without compromising performance.