Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

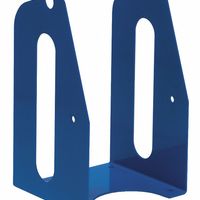

- Hydraulics

- Hydraulic Hose Crimping Machines Accessories

.....Read More

Frequently Asked Questions

What is a hydraulic hose crimping machine?

A hydraulic hose crimping machine is a specialized piece of equipment used to securely attach fittings to hydraulic hoses. This process, known as crimping, involves compressing a metal collar (or ferrule) around the hose and the fitting. The machine uses hydraulic pressure to apply a precise amount of force, ensuring a strong, leak-proof connection that can withstand the high pressures common in hydraulic systems.

These machines are essential in various industries, including construction, agriculture, manufacturing, and automotive, where hydraulic power is widely utilized. They come in various sizes and configurations, from portable manual models for field repairs to large, automated machines used in industrial production lines. Key components typically include a hydraulic pump, a set of crimping dies (specific to the hose and fitting size), and a control system to manage the crimping force and cycle. Proper crimping is critical for the safety and efficiency of hydraulic equipment, preventing hose failures and fluid leaks.

How do you use a hydraulic hose crimping machine?

To use a hydraulic hose crimping machine, first select the correct crimping dies and assemble them in the machine. Next, measure and cut the hydraulic hose to the desired length. Install the appropriate fittings onto the ends of the hose, ensuring they are seated correctly. Place the hose and fittings into the crimping machine, aligning the fitting with the crimping dies. Activate the hydraulic pump, which will advance the dies to crimp the fitting onto the hose. Monitor the pressure gauge to ensure the crimp reaches the specified pressure. Once the crimp is complete, retract the dies and remove the hose assembly. Finally, inspect the crimped connection to verify it is secure and properly formed. Regular maintenance and adherence to manufacturer guidelines are crucial for safe and effective operation.

What are the benefits of using a hydraulic hose crimping machine?

A hydraulic hose crimping machine offers numerous benefits for creating secure and leak-free hose assemblies. These machines provide precise and consistent crimps, ensuring the integrity and longevity of the hose. This precision reduces the risk of leaks, blowouts, and equipment downtime, leading to increased safety and efficiency. They are versatile, capable of crimping various hose sizes and types, from low-pressure to high-pressure applications. Using a crimping machine also saves time and labor compared to manual methods, making it a cost-effective solution for both small and large-scale operations. The consistent quality of machine-crimped hoses also helps meet industry standards and regulations.

What types of dies are compatible with hydraulic hose crimping machines?

Hydraulic hose crimping machines are designed to work with specific types of dies, which are crucial for ensuring a secure and leak-free crimp. The compatibility of dies depends primarily on the machine's model and the hose and fitting combination being used.

Common types of dies include: * **Segmented Dies:** These are the most common type, consisting of multiple segments that close around the hose and fitting to create the crimp. They are typically color-coded or labeled for easy identification of their size and profile. Different segmented die sets are required for various hose diameters and fitting styles (e.g., straight, elbow).

* **Collet Dies:** Used in some machines, collet dies have a tapered bore that compresses around the hose and fitting. They are often used for smaller diameter hoses or specific applications.

* **Specialized Dies:** Certain applications may require specialized dies, such as those for large-bore industrial hoses, thermoplastic hoses, or specific OEM (Original Equipment Manufacturer) fittings. These dies are custom-designed to meet unique crimping requirements.When selecting dies, it's essential to consider: * **Hose Size and Type:** The inner and outer diameter of the hose, as well as its construction (e.g., single wire braid, multi-spiral), dictate the appropriate die size and profile.

* **Fitting Type:** Different fittings (e.g., JIC, ORFS, flange) have unique geometries that require corresponding die profiles to achieve a proper crimp.

* **Machine Manufacturer's Specifications:** Always refer to the crimper's manual and the hose and fitting manufacturer's guidelines for recommended die sets and crimp specifications. Using incompatible dies can lead to improper crimps, hose failure, and safety hazards.

How do you maintain a hydraulic hose crimping machine?

Please specify what you would like me to elaborate on.

What is the difference between manual and automatic hydraulic hose crimping machines?

Manual hydraulic hose crimping machines require an operator to physically pump a lever or handle to generate the hydraulic pressure needed for crimping. This method offers greater control and is often more portable, making it suitable for on-site repairs or lower-volume operations. However, it can be labor-intensive and slower, especially for larger hoses or high-volume tasks.

Automatic hydraulic hose crimping machines, conversely, use an electric motor or pneumatic power to generate and control the crimping force. These machines are significantly faster and more consistent, reducing operator fatigue and increasing throughput. They often feature digital controls for precise crimp diameter adjustments and can store multiple crimping specifications. While typically more expensive and less portable, automatic machines are ideal for high-volume manufacturing environments where speed, accuracy, and repeatability are critical. The choice between manual and automatic largely depends on the required production volume, portability needs, and budget.

How do you choose the right hydraulic hose crimping machine for your needs?

Choosing the right hydraulic hose crimping machine involves several key considerations to ensure optimal performance and cost-efficiency. First, assess the types and sizes of hoses you'll be crimping. Machines vary in their capacity, from small, portable units for occasional use to large, industrial models for high-volume production. Consider the hose's material, its working pressure, and the diameter to ensure the machine's crimping force and die sets are compatible.

Next, evaluate the power source. Manual crimpers are inexpensive and portable but labor-intensive for frequent use. Electric and pneumatic machines offer faster, more consistent crimps and are suitable for higher volumes. Hydraulic-powered machines provide the highest crimping force and are ideal for large-diameter, high-pressure hoses.

Consider the machine's portability if you need to perform crimps on-site. Bench-mount machines are best for shop environments, while compact, lightweight models are available for field repairs. Ease of use and maintenance are also important; look for machines with intuitive controls and readily available spare parts. Finally, factor in your budget and the long-term cost of ownership, including power consumption and die set replacements.

What safety precautions should be taken when using a hydraulic hose crimping machine?

When using a hydraulic hose crimping machine, several safety precautions should be taken to ensure the well-being of the operator and the proper functioning of the equipment. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and sturdy footwear, to guard against potential hazards such as flying debris or hydraulic fluid leaks. Before operation, thoroughly inspect the machine for any signs of damage, wear, or leaks in the hydraulic system, hoses, or dies. Ensure that the correct dies are selected and properly installed for the specific hose and fitting combination to prevent improper crimps and potential failures.

It is crucial to understand and follow the manufacturer's instructions and operating manual for the specific crimping machine being used. This includes proper setup, pressure settings, and maintenance procedures. Always secure the hose and fitting properly in the crimper to prevent them from slipping or moving during the crimping process. Keep hands and fingers clear of the crimping dies during operation to avoid pinch points.

Maintain a clean and well-lit workspace to prevent trips or falls and to ensure clear visibility of the machine and the crimping process. Never attempt to crimp a hose that is under pressure. After crimping, inspect the finished assembly for any defects, such as insufficient crimp diameter or misaligned fittings, and perform a pressure test if required by the application to ensure the integrity of the crimped hose. Regular maintenance and proper training are essential for safe and efficient operation of hydraulic hose crimping machines.

How do you troubleshoot common issues with hydraulic hose crimping machines?

Troubleshooting common issues with hydraulic hose crimping machines involves addressing problems that can arise during the crimping process.

**Common Issues and Troubleshooting:**1. **Inconsistent Crimps:** If crimps are not uniform, check the machine's calibration. The crimp diameter may be off, or the die set could be worn or incorrect for the hose and fitting. Ensure the machine is properly zeroed and recalibrated according to the manufacturer's specifications.

2. **Leaking Hoses:** Leaks after crimping often indicate insufficient crimp pressure or an incorrect crimp diameter, leading to a loose seal. Verify the crimp diameter against specifications. It could also be due to a damaged fitting or hose during assembly, so inspect these components before crimping.

3. **Machine Not Crimping:** If the machine fails to actuate or crimp, check for power supply issues, hydraulic fluid levels, and pressure. A low fluid level or contaminated fluid can prevent proper operation. Inspect hydraulic lines and connections for leaks or blockages. The emergency stop button might also be engaged.

4. **Slow Crimping Speed:** Reduced crimping speed can be a sign of low hydraulic pressure, a clogged filter, or a failing pump. Check the pressure gauge on the machine and ensure the hydraulic filter is clean. If the pump is old or making unusual noises, it may need replacement.

5. **Excessive Noise/Vibration:** Unusual noises or vibrations during operation could indicate loose components, worn bearings, or cavitation in the hydraulic system. Check all fasteners for tightness and inspect for any visible damage. Ensure the hydraulic fluid is free of air bubbles.Regular maintenance, including checking hydraulic fluid quality, filter replacement, and recalibration, can prevent many of these issues. Always consult the machine's operating manual for specific troubleshooting steps and safety precautions.

Where can you buy hydraulic hose crimping machines and accessories?

Hydraulic hose crimping machines and accessories can be purchased from various suppliers specializing in hydraulic equipment and industrial supplies. These include: * **Specialized Hydraulic Equipment Suppliers:** Many companies focus solely on hydraulic components and systems. They often carry a wide range of crimping machines, dies, and related accessories from different manufacturers.

* **Industrial Supply Distributors:** Large industrial distributors often stock a variety of equipment for manufacturing, maintenance, and repair, including hydraulic tools.

* **Online Retailers:** E-commerce platforms and specialized online stores for industrial equipment provide a convenient way to compare models and prices from multiple vendors.

* **Direct from Manufacturers:** Some manufacturers of hydraulic crimping machines also sell directly to customers or have authorized dealer networks.When purchasing, consider factors such as the types of hoses you need to crimp, the volume of work, the machine's portability, and available technical support.