Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

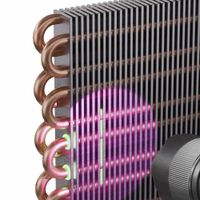

- Hvac And Refrigeration

- Hvac Diagnostics Recovery Evacuation

- Hvacr Leak Detection

.....Read More

Frequently Asked Questions

What is the best method for detecting HVACR leaks?

The best method for detecting HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) leaks is a combination of electronic leak detectors and ultrasonic leak detectors, supplemented by visual inspections and dye testing.

1. **Electronic Leak Detectors**: These devices are highly sensitive and can detect even small amounts of refrigerant gas. They work by sensing the presence of refrigerant in the air and are effective for pinpointing leaks in complex systems. Modern electronic detectors are portable, easy to use, and provide quick results.

2. **Ultrasonic Leak Detectors**: These detectors identify the sound of gas escaping from a leak. They are particularly useful in noisy environments where other methods might struggle. Ultrasonic detectors can detect leaks in both pressurized and vacuum systems, making them versatile.

3. **Visual Inspection**: Regular visual inspections of HVACR systems can help identify obvious signs of leaks, such as oil stains or frost buildup on components. While not as precise as electronic methods, visual inspections are a good first step in leak detection.

4. **Dye Testing**: This involves adding a fluorescent dye to the refrigerant system. The dye circulates with the refrigerant and escapes through leaks, which can then be identified using a UV light. Dye testing is effective for finding leaks in hard-to-reach areas and provides a visual confirmation of leak locations.

Combining these methods ensures comprehensive leak detection, as each has its strengths and limitations. Regular maintenance and inspections using these techniques can prevent system inefficiencies, reduce environmental impact, and ensure the longevity of HVACR systems.

How do electronic leak detectors work in HVAC systems?

Electronic leak detectors in HVAC systems work by identifying the presence of refrigerant gases that escape from the system. These detectors are designed to sense the specific chemical properties of refrigerants, which are used in HVAC systems for cooling and heating purposes. Here's how they function:

1. **Sensor Technology**: Electronic leak detectors use various sensor technologies, such as heated diode, infrared, or ultrasonic sensors. Each type has its own method of detecting refrigerant gases.

2. **Heated Diode Sensors**: These sensors heat a diode to a high temperature. When refrigerant gases pass over the heated diode, they break down and release ions. The detector measures the ion flow, which increases in the presence of refrigerant, indicating a leak.

3. **Infrared Sensors**: Infrared detectors use a light source and a sensor to detect refrigerant gases. The refrigerant absorbs specific wavelengths of infrared light. The detector measures the amount of light absorbed, which correlates to the concentration of refrigerant, signaling a leak.

4. **Ultrasonic Sensors**: These sensors detect the sound of gas escaping from a leak. They pick up high-frequency sounds that are inaudible to the human ear, which are produced when refrigerant gas leaks from the system.

5. **Sensitivity and Calibration**: Electronic leak detectors are highly sensitive and can detect very small amounts of refrigerant. They often require calibration to ensure accuracy and may have adjustable sensitivity settings to detect different types of refrigerants.

6. **Visual and Audible Alerts**: When a leak is detected, the device typically provides visual and audible alerts, such as flashing lights or beeping sounds, to notify the technician of the leak's presence and location.

These detectors are essential tools for HVAC technicians to ensure system efficiency, prevent environmental harm, and comply with regulations regarding refrigerant emissions.

What are the advantages of using fluorescent dye for leak detection?

Fluorescent dye for leak detection offers several advantages:

1. **High Sensitivity**: Fluorescent dyes can detect even the smallest leaks that might be missed by other methods. The dye glows under ultraviolet (UV) or blue light, making it easy to spot leaks in low-light conditions.

2. **Non-Invasive**: This method does not require disassembly of systems or components, reducing downtime and labor costs. The dye circulates with the system's fluid, identifying leaks without intrusive measures.

3. **Versatility**: Fluorescent dyes are compatible with a wide range of systems, including HVAC, automotive, hydraulic, and refrigeration systems. They work with various fluids like water, oil, and refrigerants.

4. **Cost-Effective**: The initial investment in fluorescent dye and a UV lamp is relatively low compared to other detection methods. It reduces the need for repeated inspections and repairs by accurately pinpointing leak locations.

5. **Time-Saving**: The quick identification of leaks allows for faster repairs, minimizing system downtime. This efficiency is crucial in industrial settings where time is money.

6. **Safety**: Fluorescent dyes are generally non-toxic and safe for use in most systems. They do not alter the properties of the fluid they are mixed with, ensuring system integrity.

7. **Permanent Record**: Once applied, the dye remains in the system, allowing for future inspections without reapplication. This provides a continuous monitoring solution for leak detection.

8. **Environmental Benefits**: Early detection of leaks prevents fluid loss and environmental contamination, supporting sustainability efforts and regulatory compliance.

9. **Ease of Use**: The process is straightforward, requiring minimal training. Technicians can quickly learn to apply the dye and use UV light to inspect systems.

These advantages make fluorescent dye a preferred choice for efficient and effective leak detection across various industries.

How effective are bubble leak detection products for HVAC systems?

Bubble leak detection products are moderately effective for identifying leaks in HVAC systems. These products typically consist of a liquid solution that is applied to areas where leaks are suspected. When the solution encounters escaping gas, it forms bubbles, visually indicating the presence of a leak.

The effectiveness of bubble leak detection products is influenced by several factors:

1. **Simplicity and Cost-Effectiveness**: They are easy to use and relatively inexpensive compared to electronic leak detectors. This makes them accessible for both professionals and DIY enthusiasts.

2. **Visual Confirmation**: The formation of bubbles provides immediate visual confirmation of a leak, which can be particularly useful for pinpointing the exact location of small leaks.

3. **Sensitivity**: While effective for detecting larger leaks, bubble solutions may not be sensitive enough to detect very small or micro leaks, which can still significantly impact system efficiency over time.

4. **Environmental Conditions**: The effectiveness can be reduced in windy or wet conditions, as these can disperse the bubbles or wash away the solution before a leak is detected.

5. **Application Limitations**: Bubble solutions are best suited for accessible areas. In hard-to-reach or confined spaces, applying the solution and observing the results can be challenging.

6. **Complementary Use**: For comprehensive leak detection, bubble solutions are often used in conjunction with other methods, such as electronic leak detectors, which can detect smaller leaks and provide more precise measurements.

In summary, while bubble leak detection products are a useful tool for identifying leaks in HVAC systems, they are most effective when used as part of a broader leak detection strategy. They offer a straightforward and cost-effective solution for detecting larger leaks but may need to be supplemented with other methods for a thorough assessment.

Can smoke leak detection be used for all types of HVAC equipment?

Smoke leak detection can be used for various types of HVAC equipment, but its applicability and effectiveness depend on several factors. Smoke leak detection systems are designed to identify leaks in ductwork and other components by introducing a non-toxic, visible smoke into the system and observing where it escapes. This method is particularly useful for identifying leaks in air ducts, plenums, and other enclosed spaces within HVAC systems.

For residential and commercial HVAC systems, smoke leak detection can be effective in identifying leaks that may lead to energy inefficiency, poor indoor air quality, and compromised system performance. It is suitable for use in systems with accessible ductwork and components where visual inspection is feasible.

However, smoke leak detection may not be suitable for all types of HVAC equipment. In systems with complex or inaccessible ductwork, such as those in large industrial settings, the method may be less practical. Additionally, in environments where the introduction of smoke could interfere with sensitive equipment or processes, alternative leak detection methods, such as ultrasonic or infrared thermography, may be more appropriate.

Furthermore, smoke leak detection is not typically used for detecting refrigerant leaks in HVAC systems. Refrigerant leaks require specialized detection equipment, such as electronic leak detectors or dye testing, due to the nature of the substances involved and the potential environmental and health impacts.

In summary, while smoke leak detection can be a valuable tool for identifying leaks in many types of HVAC equipment, its use is contingent upon the system's design, accessibility, and the specific requirements of the environment in which the equipment operates. It is important to assess the suitability of this method on a case-by-case basis and consider alternative detection methods when necessary.

How often should HVAC systems be checked for leaks?

HVAC systems should be checked for leaks at least once a year. Regular maintenance is crucial to ensure the system operates efficiently and to prevent potential issues that could lead to costly repairs or replacements. During these annual inspections, a professional technician will examine the system for any signs of refrigerant leaks, which can significantly impact the system's performance and energy efficiency.

In addition to the annual check, it is advisable to monitor the system for any signs of leaks throughout the year. Indicators of a potential leak include a noticeable decrease in cooling or heating efficiency, unusual hissing sounds, or ice formation on the evaporator coils. If any of these symptoms are observed, it is important to schedule an inspection immediately, regardless of the last maintenance date.

For commercial HVAC systems or those in regions with extreme weather conditions, more frequent inspections may be necessary. In such cases, bi-annual checks, typically before the start of the heating and cooling seasons, can help ensure the system is prepared to handle the increased demand.

Regular inspections not only help in identifying leaks but also contribute to the overall longevity and efficiency of the HVAC system. They allow for the early detection of other potential issues, such as clogged filters or malfunctioning components, which can be addressed before they escalate into major problems. By maintaining a consistent inspection schedule, homeowners and businesses can ensure their HVAC systems operate smoothly, providing comfort and energy savings throughout the year.

What are the signs of a refrigerant leak in an HVAC system?

Signs of a refrigerant leak in an HVAC system include:

1. **Reduced Cooling Efficiency**: The system struggles to maintain the desired temperature, leading to longer running times and insufficient cooling.

2. **Higher Energy Bills**: Due to reduced efficiency, the system consumes more energy, resulting in increased utility costs.

3. **Ice Formation on Evaporator Coils**: Low refrigerant levels cause the evaporator coils to become too cold, leading to ice buildup.

4. **Hissing or Bubbling Sounds**: These noises can indicate a refrigerant leak, as they may result from escaping gas.

5. **Warm Air from Vents**: Instead of cool air, the system may blow warm air due to inadequate refrigerant levels.

6. **Oil Stains or Residue**: Leaks can cause oil to escape along with the refrigerant, leaving stains or residue around the HVAC unit.

7. **Unpleasant Odors**: A chemical smell may be noticeable if the refrigerant is leaking.

8. **Frequent Cycling**: The system may turn on and off more frequently as it struggles to maintain the set temperature.

9. **Visible Damage or Corrosion**: Physical damage or corrosion on the refrigerant lines can be a sign of a leak.

10. **Increased Humidity Levels**: The system may fail to dehumidify the air effectively, leading to higher indoor humidity.

11. **System Alerts or Error Codes**: Modern HVAC systems may display error codes or alerts indicating a refrigerant issue.

12. **Professional Detection**: HVAC technicians can use specialized tools like electronic leak detectors or UV dye to identify leaks.

If you suspect a refrigerant leak, it is crucial to contact a professional technician to diagnose and repair the issue, as handling refrigerants requires specialized knowledge and equipment.