Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

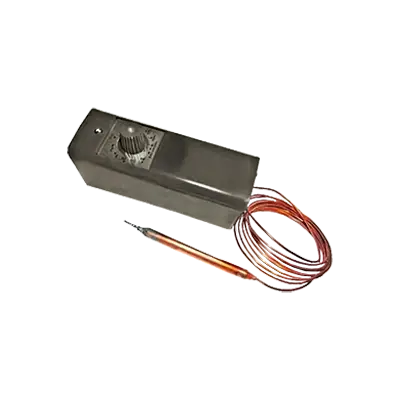

- Hvac And Refrigeration

- Hvac Controls And Thermostats

- Hvac Equipment Controls Components

- Temperature Controls

.....Read More

Frequently Asked Questions

What is the difference between electronic and mechanical temperature controls?

Electronic temperature controls use digital sensors and microprocessors to monitor and adjust temperature settings. They offer precise temperature regulation, programmable settings, and often include features like remote access and integration with smart home systems. These controls can quickly respond to temperature changes and provide detailed feedback through digital displays.

Mechanical temperature controls, on the other hand, rely on physical components such as bimetallic strips, bulbs, and capillary tubes to regulate temperature. They are generally simpler, more robust, and less expensive than electronic controls. Mechanical systems adjust temperature based on physical changes in materials, such as expansion or contraction, and are typically less precise than electronic systems.

In summary, electronic controls offer precision, programmability, and advanced features, while mechanical controls provide simplicity, durability, and cost-effectiveness.

How do electronic temperature controls work in HVAC systems?

Electronic temperature controls in HVAC systems work by using sensors, controllers, and actuators to maintain desired temperature settings. Sensors measure the current temperature and send this data to the controller. The controller, often a microprocessor-based device, compares the actual temperature with the setpoint temperature programmed by the user.

When the actual temperature deviates from the setpoint, the controller sends signals to actuators to adjust the HVAC system's components, such as compressors, fans, or valves. For example, if the room is too warm, the controller might activate the air conditioning unit or increase the fan speed to cool the space. Conversely, if the room is too cold, it might activate the heating system.

These systems often incorporate Proportional-Integral-Derivative (PID) control algorithms to ensure precise temperature regulation. The PID controller continuously calculates an error value as the difference between the desired setpoint and the measured temperature and applies corrections based on proportional, integral, and derivative terms.

Additionally, electronic temperature controls can be integrated with building management systems (BMS) for centralized monitoring and control, allowing for energy efficiency and remote access. They may also feature programmable schedules, allowing users to set different temperatures for different times of the day or week, optimizing comfort and energy use.

Overall, electronic temperature controls enhance the efficiency, accuracy, and convenience of HVAC systems, ensuring optimal indoor climate conditions.

What are the advantages of using electronic temperature controls over mechanical ones?

Electronic temperature controls offer several advantages over mechanical ones:

1. **Precision and Accuracy**: Electronic controls provide more precise temperature regulation, maintaining consistent temperatures with minimal fluctuations.

2. **Programmability**: They allow for programmable settings, enabling users to set different temperatures for different times of the day or week, enhancing energy efficiency.

3. **Energy Efficiency**: By maintaining optimal temperatures and reducing unnecessary heating or cooling, electronic controls can lead to significant energy savings.

4. **Remote Access and Automation**: Many electronic systems can be integrated with smart home systems, allowing for remote monitoring and control via smartphones or computers.

5. **Advanced Features**: They often come with additional features such as alerts, diagnostics, and data logging, which can help in identifying issues and optimizing performance.

6. **User-Friendly Interfaces**: Electronic controls typically have digital displays and intuitive interfaces, making them easier to use and adjust compared to mechanical dials.

7. **Reliability and Durability**: With fewer moving parts, electronic controls are generally more reliable and have a longer lifespan than mechanical ones.

8. **Integration with Other Systems**: They can be easily integrated with other electronic systems, such as HVAC, for comprehensive climate control solutions.

9. **Environmental Impact**: By optimizing energy use, electronic controls contribute to reduced carbon emissions and a smaller environmental footprint.

10. **Customization**: Users can customize settings to suit specific needs, such as different zones in a building, enhancing comfort and efficiency.

Overall, electronic temperature controls offer enhanced functionality, efficiency, and convenience compared to mechanical controls.

How do mechanical temperature controls function?

Mechanical temperature controls function by using physical components to regulate temperature without the need for electronic systems. These controls typically involve a thermostat, which is a device that senses temperature changes and activates a response to maintain a desired setpoint.

The core component of a mechanical thermostat is often a bimetallic strip or a gas-filled bellows. A bimetallic strip consists of two different metals bonded together, each with a different coefficient of thermal expansion. As temperature changes, the strip bends due to the differing expansion rates of the metals. This bending action can open or close an electrical circuit, turning a heating or cooling device on or off.

In some designs, a gas-filled bellows or diaphragm is used. As the temperature changes, the gas inside expands or contracts, causing the bellows to move. This movement can be used to operate a switch or valve, controlling the flow of electricity or fluid to a heating or cooling system.

Mechanical temperature controls are often found in older heating, ventilation, and air conditioning (HVAC) systems, as well as in appliances like ovens and refrigerators. They are valued for their simplicity, reliability, and lack of dependence on electronic components, making them less susceptible to power surges or electronic failures.

The setpoint, or desired temperature, is usually adjusted manually by turning a dial or moving a lever, which changes the position of the bimetallic strip or bellows, altering the temperature at which the system activates. These controls provide a straightforward and effective means of temperature regulation, though they may lack the precision and programmability of modern electronic thermostats.

What are the common issues with temperature controls in HVAC systems?

Common issues with temperature controls in HVAC systems include:

1. **Thermostat Malfunctions**: Faulty thermostats can lead to inaccurate temperature readings, causing the system to overheat or underheat spaces.

2. **Improper Calibration**: Incorrect calibration of thermostats can result in inefficient temperature regulation, leading to discomfort and energy wastage.

3. **Sensor Issues**: Malfunctioning or poorly placed sensors can provide incorrect data, causing the system to respond inappropriately to temperature changes.

4. **Zoning Problems**: Inadequate zoning can lead to uneven temperature distribution, with some areas being too hot or too cold.

5. **Airflow Obstructions**: Blocked vents or ducts can restrict airflow, preventing the system from maintaining the desired temperature.

6. **Refrigerant Leaks**: Low refrigerant levels can impair the system's ability to cool, leading to temperature inconsistencies.

7. **Dirty Filters**: Clogged filters can reduce airflow and efficiency, causing the system to struggle to maintain set temperatures.

8. **Electrical Issues**: Faulty wiring or connections can disrupt the communication between the thermostat and the HVAC system.

9. **Aging Equipment**: Older systems may have worn-out components that affect temperature control accuracy and efficiency.

10. **Improper Sizing**: An HVAC system that is too large or too small for the space can lead to poor temperature regulation and increased energy consumption.

11. **Software Glitches**: In systems with digital controls, software bugs can cause erratic temperature control behavior.

12. **Lack of Maintenance**: Infrequent maintenance can lead to the accumulation of issues that affect temperature control, such as dirt buildup and component wear.

Addressing these issues typically involves regular maintenance, proper installation, and timely repairs to ensure efficient and accurate temperature control.

How can I troubleshoot temperature control problems in my HVAC system?

1. **Check Thermostat Settings**: Ensure the thermostat is set to the correct mode (heating or cooling) and the desired temperature. Replace batteries if necessary.

2. **Inspect Air Filters**: Dirty or clogged filters can restrict airflow, causing temperature inconsistencies. Replace or clean filters regularly.

3. **Examine Circuit Breakers**: Ensure the HVAC system's circuit breakers are not tripped. Reset if needed.

4. **Inspect Vents and Registers**: Ensure all vents and registers are open and unobstructed to allow proper airflow throughout the space.

5. **Check for Air Leaks**: Inspect windows, doors, and ductwork for leaks that could be causing temperature fluctuations. Seal any gaps or cracks.

6. **Evaluate Ductwork**: Ensure ducts are properly connected and insulated. Look for signs of damage or disconnection.

7. **Inspect Outdoor Unit**: Clear debris around the outdoor unit and ensure it has adequate clearance for airflow. Check for visible damage.

8. **Test Blower Motor**: Listen for unusual noises from the blower motor, which could indicate a problem. Ensure it is running smoothly.

9. **Check Refrigerant Levels**: Low refrigerant can affect cooling efficiency. Contact a professional to check and refill if necessary.

10. **Examine Furnace or Heat Pump**: Ensure the furnace or heat pump is functioning correctly. Look for error codes or unusual noises.

11. **Review System Age and Maintenance**: Older systems may require more frequent maintenance or replacement. Ensure regular professional maintenance is performed.

12. **Consult a Professional**: If problems persist, contact a licensed HVAC technician for a thorough inspection and diagnosis.

What factors should be considered when choosing a temperature control system for commercial HVAC?

1. **System Compatibility**: Ensure the temperature control system is compatible with the existing HVAC infrastructure to avoid costly modifications.

2. **Energy Efficiency**: Opt for systems that enhance energy efficiency, reducing operational costs and environmental impact.

3. **Scalability**: Choose a system that can accommodate future expansions or modifications in the HVAC setup.

4. **User Interface**: A user-friendly interface is crucial for ease of operation and quick adjustments by facility managers.

5. **Integration Capabilities**: The system should integrate seamlessly with other building management systems for centralized control.

6. **Reliability and Durability**: Select a system known for its reliability and durability to minimize maintenance and downtime.

7. **Cost**: Consider both initial investment and long-term operational costs, including maintenance and potential energy savings.

8. **Customization**: The ability to customize settings for different zones or areas within the building is important for optimal comfort and efficiency.

9. **Remote Access**: Systems with remote monitoring and control capabilities offer convenience and flexibility in management.

10. **Regulatory Compliance**: Ensure the system complies with local regulations and standards for commercial buildings.

11. **Vendor Support and Service**: Evaluate the level of support and service provided by the vendor, including warranties and technical assistance.

12. **Data Analytics**: Advanced systems with data analytics can provide insights into usage patterns and help optimize performance.

13. **Security**: Ensure robust security features to protect against unauthorized access and cyber threats.

14. **Environmental Impact**: Consider systems that use eco-friendly technologies and refrigerants to minimize environmental impact.

15. **Feedback and Reviews**: Research feedback and reviews from other users to gauge performance and satisfaction levels.