Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

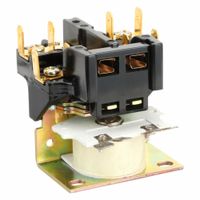

- Hvac And Refrigeration

- Hvac Controls And Thermostats

- Hvac Equipment Controls Components

- Hvac Relays Sequencers

.....Read More

Frequently Asked Questions

What is the function of a relay in an HVAC system?

A relay in an HVAC system functions as an electrically operated switch that controls the flow of electricity to various components within the system. It acts as an intermediary between the low-voltage control circuit and the high-voltage operational components, such as compressors, fans, and blowers. The primary purpose of a relay is to enable the control system, typically a thermostat, to manage the operation of these components without directly handling high voltage, ensuring safety and efficiency.

When the thermostat sends a low-voltage signal to the relay, it energizes an electromagnet within the relay. This electromagnet creates a magnetic field that pulls a set of contacts together, closing the circuit and allowing high-voltage electricity to flow to the designated component. Once the desired temperature is reached, the thermostat sends another signal to de-energize the relay, opening the contacts and cutting off the power supply to the component.

Relays are crucial for protecting the control system from high voltage and current, preventing potential damage or hazards. They also allow for the automation of the HVAC system, enabling it to respond to temperature changes and user settings without manual intervention. Additionally, relays can be used to control multiple components simultaneously or in sequence, enhancing the system's operational flexibility and efficiency.

In summary, relays in an HVAC system serve as critical components that facilitate the safe and efficient operation of high-voltage equipment by using low-voltage control signals, ensuring the system operates effectively while protecting both the equipment and users.

How do HVAC sequencers work?

HVAC sequencers are devices used to control the sequence and timing of electrical circuits in heating, ventilation, and air conditioning systems, particularly in electric furnaces and heat pumps. They ensure that the system's components, such as heating elements and blowers, are activated in a specific order to prevent electrical overload and ensure efficient operation.

A sequencer typically consists of a bimetallic strip or a solid-state relay. When the thermostat calls for heat, it sends a low-voltage signal to the sequencer. The bimetallic strip inside the sequencer heats up and bends, closing the electrical contacts. This process takes a few seconds to a minute, allowing the first set of heating elements to activate. As the strip continues to heat, it sequentially closes additional contacts, activating more heating elements and the blower motor in a staggered manner.

This staggered activation prevents a sudden surge of electrical current, which could trip circuit breakers or damage components. Once the desired temperature is reached, the thermostat stops sending the signal, and the bimetallic strip cools down, opening the contacts in reverse order. This ensures that the blower continues to run for a short period after the heating elements are deactivated, dissipating residual heat and improving efficiency.

In modern systems, solid-state sequencers may replace bimetallic ones, offering more precise control and faster response times. These use electronic components to manage the timing and sequence of operations, enhancing reliability and reducing wear.

Overall, HVAC sequencers play a crucial role in the safe and efficient operation of heating systems by managing the electrical load and ensuring components are activated in the correct order.

What are the signs of a faulty HVAC relay?

Signs of a faulty HVAC relay include:

1. **System Not Turning On or Off**: If the HVAC system fails to start or shut down, it may indicate a relay issue. The relay is responsible for sending power to the system, and a malfunction can disrupt this process.

2. **Intermittent Operation**: The system may operate sporadically, turning on and off at irregular intervals. This inconsistency can be due to a relay that is not consistently making or breaking the electrical connection.

3. **Unusual Noises**: Clicking or buzzing sounds from the HVAC unit can suggest a relay problem. These noises occur when the relay struggles to open or close the circuit.

4. **Burnt Smell**: A burnt odor near the HVAC unit can indicate a relay that is overheating or has burnt out, often due to electrical arcing or excessive current.

5. **No Response to Thermostat**: If the HVAC system does not respond to thermostat settings, the relay might be failing to transmit the necessary signals to the system components.

6. **Blown Fuses or Tripped Breakers**: Frequent tripping of circuit breakers or blowing of fuses can be a sign of a short circuit within the relay, causing excessive current draw.

7. **Visible Damage**: Physical inspection may reveal signs of damage such as burnt contacts, melted plastic, or corrosion on the relay, indicating it is not functioning properly.

8. **Inconsistent Temperature Control**: The system may fail to maintain the set temperature, cycling too frequently or not enough, due to relay issues affecting the compressor or fan operation.

9. **Increased Energy Bills**: A malfunctioning relay can cause the system to run inefficiently, leading to higher energy consumption and increased utility costs.

How do you test an HVAC relay?

1. **Safety First**: Turn off the power to the HVAC system at the circuit breaker to prevent electrical shock.

2. **Access the Relay**: Locate the relay in the HVAC system. It is usually found in the control panel or near the blower motor.

3. **Visual Inspection**: Check for any visible signs of damage, such as burnt marks or corrosion on the relay or its connections.

4. **Identify Terminals**: Note the relay's terminals, typically labeled as common (C), normally open (NO), and normally closed (NC).

5. **Multimeter Setup**: Set a multimeter to the continuity or resistance (ohms) setting.

6. **Test Coil Resistance**: Disconnect the relay from the circuit. Measure the resistance across the coil terminals. A typical reading is between 50 to 200 ohms. Infinite resistance indicates a broken coil, while zero indicates a short.

7. **Test Contacts**:

- **Normally Open (NO) Contacts**: With the relay de-energized, check for continuity between the common (C) and normally open (NO) terminals. There should be no continuity.

- **Normally Closed (NC) Contacts**: Check for continuity between the common (C) and normally closed (NC) terminals. There should be continuity.

8. **Energize the Relay**: Reconnect the relay and restore power. Activate the HVAC system to energize the relay.

9. **Check Operation**:

- **NO Contacts**: With the relay energized, check for continuity between the common (C) and normally open (NO) terminals. There should now be continuity.

- **NC Contacts**: Check for no continuity between the common (C) and normally closed (NC) terminals.

10. **Final Steps**: If the relay fails any test, it should be replaced. Turn off the power again before replacing the relay. Reassemble the system and restore power to ensure proper operation.

What is the difference between a relay and a sequencer in HVAC systems?

A relay and a sequencer in HVAC systems serve different functions, though both are involved in controlling electrical circuits.

A relay is an electromechanical switch used to control a high-power circuit with a low-power signal. It consists of a coil and one or more sets of contacts. When the coil is energized, it creates a magnetic field that closes or opens the contacts, thus controlling the flow of electricity. Relays are used in HVAC systems to switch components like compressors, fans, and pumps on and off. They provide isolation between the control circuit and the high-power circuit, ensuring safety and reliability.

A sequencer, on the other hand, is a device used to control the timing and order of operations in an HVAC system, particularly in electric furnaces. It ensures that heating elements are energized in a specific sequence to prevent overloading the electrical system. Sequencers typically contain multiple bimetallic strips or electronic timers that activate at different intervals. This staggered activation allows for a gradual increase in power demand, reducing the risk of tripping circuit breakers and ensuring efficient operation.

In summary, the primary difference lies in their functions: relays are used for switching electrical circuits on and off, while sequencers manage the timing and order of operations to ensure safe and efficient system performance.

How do you replace an HVAC relay or sequencer?

1. **Turn Off Power**: Switch off the power to the HVAC system at the circuit breaker to ensure safety.

2. **Access the Unit**: Remove the access panel on the HVAC unit to locate the relay or sequencer. This may require a screwdriver.

3. **Identify the Component**: Locate the relay or sequencer. It is typically a small box with several wires connected to it.

4. **Label Wires**: Before disconnecting, label each wire connected to the relay or sequencer using masking tape and a marker to ensure correct reconnection.

5. **Disconnect Wires**: Carefully disconnect the wires from the relay or sequencer using needle-nose pliers. Avoid pulling on the wires directly to prevent damage.

6. **Remove the Component**: Unscrew or unclip the relay or sequencer from its mounting position.

7. **Install New Component**: Position the new relay or sequencer in place and secure it with screws or clips.

8. **Reconnect Wires**: Attach the wires to the new relay or sequencer, ensuring each wire is connected to the correct terminal as per the labels.

9. **Double-Check Connections**: Verify all connections are secure and correctly placed.

10. **Replace Access Panel**: Reattach the access panel to the HVAC unit.

11. **Restore Power**: Turn the power back on at the circuit breaker.

12. **Test the System**: Turn on the HVAC system to ensure it operates correctly with the new relay or sequencer.

13. **Observe Operation**: Monitor the system for a few cycles to confirm proper functioning.

14. **Dispose of Old Component**: Properly dispose of the old relay or sequencer according to local regulations.

What causes an HVAC relay or sequencer to fail?

An HVAC relay or sequencer can fail due to several reasons:

1. **Electrical Overload**: Excessive current can cause the relay contacts to weld together or burn out, leading to failure.

2. **Mechanical Wear**: Over time, the mechanical components of a relay or sequencer can wear out due to repeated cycling, causing them to stick or fail to engage.

3. **Voltage Spikes**: Sudden voltage spikes or surges can damage the coil or contacts, leading to malfunction.

4. **Corrosion**: Moisture or contaminants can cause corrosion on the contacts, leading to poor conductivity and eventual failure.

5. **Heat Damage**: Excessive heat, often from poor ventilation or high ambient temperatures, can degrade the materials in the relay or sequencer, causing them to fail.

6. **Manufacturing Defects**: Faulty components or poor assembly during manufacturing can lead to premature failure.

7. **Improper Installation**: Incorrect installation, such as wrong wiring or mounting, can lead to operational issues and failure.

8. **Aging**: Over time, the materials in the relay or sequencer can degrade, leading to failure due to age-related wear and tear.

9. **Short Circuits**: Short circuits in the system can cause excessive current flow, damaging the relay or sequencer.

10. **Environmental Factors**: Exposure to dust, dirt, or other environmental factors can lead to contamination and failure.

11. **Inadequate Maintenance**: Lack of regular maintenance can lead to the accumulation of dirt and debris, causing operational issues and failure.

12. **Overuse**: Continuous or excessive use beyond the designed capacity can lead to overheating and failure.

Addressing these issues through regular maintenance, proper installation, and using quality components can help prevent relay or sequencer failure.