- Home

- Hvac And Refrigeration

- Hvac Controls And Thermostats

- Hvac Equipment Controls Components

- Air Conditioning Refrigeration Controls

.....Read More

Compressor Hard Start Kits

Condenser Fan Speed Controls

Defrost Termination & Fan Delay Controls

Defrost Thermostats

Differential Pressure Refrigerant Controls

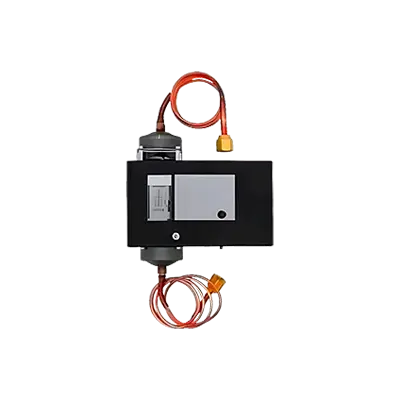

Dual-Pressure Refrigerant Controls

Heat Pump Reversing Valves & Solenoid Coils

Lube Oil Pressure Controls

Potential Relays

Refrigeration Defrost Cycle Controls

Refrigeration Temperature Controls

Room Air Conditioner Temperature Controls

Single-Pressure Refrigerant Controls

Frequently Asked Questions

What are the main components of an air conditioning and refrigeration control system?

How do pressure controls work in air conditioning and refrigeration systems?

What is the function of refrigeration cold controls?

How do defrost thermostats prevent frost buildup?

How do room air conditioner temperature controls operate PTACs?

What is the role of potential relays in safeguarding motors and start capacitors?

How do compressor hard start kits assist in starting high-powered components?