Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Fleet Vehicle Maintenance

- Garage Equipment

.....Read More

Frequently Asked Questions

What are the essential garage equipment supports for fleet vehicle maintenance?

Essential garage equipment for fleet vehicle maintenance includes: * Vehicle lifts: Crucial for undercarriage access for inspections, repairs, and fluid changes. Various types exist, such as two-post, four-post, and scissor lifts, each suited for different vehicle types and tasks.

* Diagnostic tools: Scan tools and diagnostic software are vital for identifying electronic issues, reading fault codes, and monitoring vehicle performance. This includes multimeters, oscilloscopes, and specialized brand-specific diagnostic equipment.

* Fluid management systems: Systems for dispensing and collecting engine oil, transmission fluid, coolant, and other vehicle fluids efficiently and cleanly are important. This includes waste oil drains, oil dispensing reels, and fluid transfer pumps.

* Tire service equipment: Tire changers and wheel balancers are necessary for proper tire maintenance, rotations, and replacements. This also includes tire inflation equipment and alignment machines.

* Air compressors and pneumatic tools: A reliable air compressor is fundamental for powering various pneumatic tools like impact wrenches, air hammers, and paint sprayers, as well as for tire inflation.

* Workbenches and storage: Sturdy workbenches, tool chests, and shelving units are essential for organizing tools, parts, and providing a clean workspace.

* Safety equipment: This includes personal protective equipment (PPE) like safety glasses, gloves, and ear protection, as well as fire extinguishers, first aid kits, and spill containment kits to ensure a safe working environment.

* Specialized tools: Depending on the fleet, this might include specific tools for heavy-duty vehicles, hybrid or electric vehicles, or specialized engine repairs.

How do vehicle lifting and support equipment work?

Vehicle lifting and support equipment are essential tools in automotive repair and maintenance, allowing technicians to safely raise vehicles for inspection, service, and repair. These tools typically work on principles of hydraulics, pneumatics, or mechanical leverage.

Hydraulic lifts, common in professional garages, use a pressurized fluid system to generate the force needed to lift a vehicle. An electric motor or air compressor powers a pump, which pushes hydraulic fluid into a cylinder. The fluid exerts pressure on a piston, extending a ram that lifts the vehicle. Releasing a valve allows the fluid to return to a reservoir, lowering the vehicle. Examples include two-post lifts, four-post lifts, and scissor lifts, each designed for specific types of vehicles and tasks.

Pneumatic systems, while less common for full vehicle lifts, are often used in support equipment like air jacks or tire changers. They utilize compressed air to create pressure, which then drives a piston or diaphragm to perform the lifting or clamping action.

Mechanical lifting devices, such as floor jacks and jack stands, rely on gears, screws, or levers to manually raise and support a vehicle. Floor jacks typically use a hydraulic pump that is hand-operated to lift, while jack stands provide stable, fixed support once the vehicle is at the desired height. Jack stands are crucial for safety, as they bear the weight of the vehicle, allowing the lift or jack to be removed or used for other purposes.

Regardless of the mechanism, safety is paramount. All lifting and support equipment must be used on a level surface, within their weight capacities, and in accordance with manufacturer guidelines to prevent accidents and injuries. Regular maintenance and inspection of this equipment are also vital to ensure its continued safe and reliable operation.

What are the benefits of using creepers for vehicle maintenance?

Using creepers for vehicle maintenance offers several significant benefits, primarily enhancing comfort, safety, and efficiency.

Firstly, creepers provide a comfortable way for mechanics to work underneath vehicles for extended periods. Instead of lying on a hard concrete floor, which can cause back pain and discomfort, a creeper allows a technician to glide smoothly and comfortably. This comfort reduces fatigue, enabling them to focus better on the task at hand and work for longer durations without needing frequent breaks.

Secondly, creepers significantly improve safety. They eliminate the need to awkwardly contort the body or slide on the floor, which can lead to scrapes, bruises, or more severe injuries. By keeping the body elevated and stable, creepers reduce the risk of slips and falls, especially when working in tight or greasy spaces.

Finally, creepers boost efficiency. The ability to roll easily from one end of the vehicle to the other without having to get up and reposition saves valuable time and energy. This seamless mobility allows mechanics to access different areas under the vehicle quickly, retrieve tools, or move around obstructions without interruption. The increased maneuverability translates into faster diagnosis and repair times, making the overall maintenance process more streamlined and productive.

How do garage dollies assist in wheel and brake repairs?

Garage dollies are essential tools that significantly streamline wheel and brake repairs, making the process safer and more efficient. Their primary function is to facilitate the easy and precise movement of heavy components like wheels, tires, and brake assemblies, especially when dealing with larger vehicles such as trucks or SUVs.

One key way they assist is by eliminating the need for manual lifting, which can be strenuous and hazardous. Technicians can simply slide a dolly under the wheel or brake assembly, lift it slightly using the dolly's mechanism (often a foot pedal or lever), and then effortlessly roll it to a workbench or storage area. This not only reduces the risk of back injuries but also speeds up the overall repair time.

Furthermore, garage dollies often feature swivel casters, allowing for omnidirectional movement. This maneuverability is particularly beneficial in tight garage spaces, enabling technicians to position the wheel or brake assembly exactly where it needs to be for repair or reinstallation. Some dollies also come with adjustable cradles or supports, ensuring a stable and secure hold on the component, preventing accidental slips or damage during transport. By providing a stable and mobile platform, garage dollies enhance precision during delicate operations like brake caliper adjustments or wheel stud alignment, ultimately contributing to a higher quality and safer repair.

What equipment is necessary for tire changing and balancing?

To effectively change and balance tires, several essential pieces of equipment are necessary. A tire changer machine is fundamental, designed to remove and mount tires onto rims. This machine often includes a bead breaker to detach the tire from the rim, and a mounting head to guide the tire on and off. For balancing, a wheel balancer machine is crucial. This machine spins the wheel to detect imbalances and indicates where to place weights to ensure smooth rotation.

Additional tools include a jack to lift the vehicle, and jack stands for safety and stability. A lug wrench or impact gun is needed to remove and tighten lug nuts that secure the wheel to the vehicle. A tire pressure gauge is used to check and adjust tire inflation to the recommended levels. Valve stem tools are helpful for servicing the valve stems, and tire levers can assist with stubborn beads. For accuracy and safety, a torque wrench is indispensable to ensure lug nuts are tightened to the manufacturer's specified torque. Lastly, safety glasses and gloves are always recommended for personal protection during the process.

How do oil filter crushers contribute to waste reduction?

Oil filter crushers significantly contribute to waste reduction by compacting used oil filters into dense, disposable pucks. This process reduces the volume of the filters by up to 85%, freeing up valuable landfill space and lowering transportation costs for disposal. Beyond space saving, these machines extract residual oil, which can then be recycled or refined, preventing it from contaminating landfills or wastewater. By crushing the filters, the metal components become more accessible for recycling, turning what would otherwise be hazardous waste into a valuable resource. This reduces the demand for virgin materials and lessens the environmental impact associated with their production. Overall, oil filter crushers promote a more sustainable waste management practice by minimizing waste volume, recovering valuable oil, and facilitating metal recycling.

What are the best practices for using fuel cans and caddies safely?

To safely use fuel cans and caddies, always store them in a well-ventilated area away from direct sunlight, heat sources, and open flames. Ensure containers are approved for fuel storage and clearly labeled. When filling, place the container on the ground to prevent static electricity buildup, and avoid overfilling to allow for expansion. Use a funnel to prevent spills.

Transport fuel cans securely in a vehicle to prevent tipping or rolling. Never transport them inside the passenger compartment; instead, use a truck bed or trailer. Before dispensing fuel, turn off the engine and avoid smoking. Use proper grounding techniques to prevent static sparks.

Regularly inspect cans and caddies for leaks, cracks, or damage. Replace any compromised containers immediately. Keep them out of reach of children and pets. Proper handling and storage minimize fire hazards and ensure safe fuel management.

How do vehicle extended reach platforms improve maintenance efficiency?

Vehicle extended reach platforms, such as boom lifts and scissor lifts, significantly enhance maintenance efficiency by providing safe and direct access to elevated or hard-to-reach areas. This eliminates the need for less efficient methods like ladders or scaffolding, which require more setup time and can pose greater safety risks.

By offering stable and spacious work areas at height, these platforms allow technicians to bring tools and equipment directly to the work site, reducing trips up and down and minimizing downtime. This direct access leads to quicker task completion, particularly for routine inspections, repairs, and installations on large machinery, infrastructure, or buildings.

Furthermore, the maneuverability of these platforms enables precise positioning, allowing technicians to work more comfortably and effectively. This improved ergonomics can reduce fatigue and enhance the quality of work, contributing to long-term efficiency gains. The inherent safety features of these platforms also lead to fewer accidents and injuries, which can otherwise cause significant delays and costs. In essence, by improving access, safety, and operational flow, extended reach platforms streamline maintenance operations and boost overall productivity.

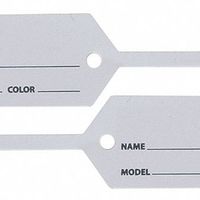

What is the importance of vehicle key tags in service departments?

Vehicle key tags are crucial in service departments for several reasons. Primarily, they provide efficient organization and identification of vehicles. With numerous cars coming in for service, key tags, often color-coded or numbered, help staff quickly locate the correct keys for the right vehicle, preventing mix-ups and saving valuable time. This streamlined process improves operational efficiency and reduces wait times for customers.

Secondly, key tags enhance accountability and security. Each tag can be linked to a specific work order or customer, ensuring that keys are tracked throughout the service process. This minimizes the risk of lost or misplaced keys and adds a layer of security, as only authorized personnel can access them.

Furthermore, key tags can carry important information, such as the customer's name, vehicle make/model, or service advisor. This quick reference aids in personalized customer service and ensures that service technicians have immediate access to relevant details, improving communication and accuracy. In essence, key tags are a simple yet indispensable tool that underpins the smooth, secure, and efficient operation of any vehicle service department.

How do vehicle protection covers prevent damage during storage or transport?

Please specify the topic you would like me to elaborate on.