Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

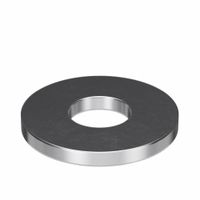

What is the purpose of a washer in a fastener assembly?

Washers distribute the load of a fastener, preventing damage to the material being fastened and ensuring a more secure connection. They also provide a smooth bearing surface, reduce friction during tightening, and can act as a spacer or a seal.

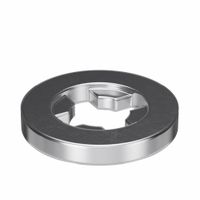

How do flat washers differ from lock washers?

Flat washers and lock washers serve different purposes in fastening applications. Flat washers are primarily used to distribute the load of a fastener over a larger area, preventing damage to the surface of the material being joined and ensuring a more secure connection. They also help to prevent the fastener head or nut from embedding into softer materials. Lock washers, on the other hand, are designed to prevent fasteners from loosening due to vibration, thermal expansion and contraction, or other dynamic forces. They achieve this by creating friction or a mechanical lock that resists rotation. Common types of lock washers include split lock washers, which have a split and spring-like action to create tension, and tooth lock washers, which have teeth that bite into both the fastener and the mating surface. In summary, flat washers distribute load and protect surfaces, while lock washers prevent loosening.

When should sealing washers be used?

Sealing washers are used in applications where a secure, leak-proof seal is essential, typically to prevent the passage of fluids or gases. They are commonly employed in situations involving bolts, screws, or nuts where a tight seal is required between a fastener and a surface, or between two components.

Key scenarios for their use include: * **Fluid Systems:** In plumbing, hydraulic, or pneumatic systems, sealing washers (often made of rubber, silicone, or specialized composites) are critical to prevent leaks around pipe fittings, valves, and pumps.

* **Automotive Industry:** They are widely used in engines, transmissions, and braking systems to contain oil, fuel, and other fluids, ensuring operational integrity and preventing environmental contamination.

* **Electrical Enclosures:** To protect internal components from moisture, dust, and other environmental factors, sealing washers can be used with fasteners on enclosures, ensuring the longevity and reliability of electrical equipment.

* **Outdoor and Marine Applications:** Due to their exposure to harsh weather and water, equipment used outdoors or in marine environments benefits from sealing washers to prevent corrosion and maintain functionality.

* **Pressure Applications:** In systems under pressure, sealing washers provide the necessary compression to maintain the integrity of the seal, preventing blow-outs or gradual leaks.The choice of sealing washer material depends on the specific application's requirements, including temperature, pressure, chemical compatibility, and environmental exposure.

What materials are washers typically made from?

Washers are typically made from a variety of materials, each chosen for specific properties to suit different applications. Common materials include various metals like steel (plain, galvanized, stainless), brass, copper, and aluminum. Steel washers are widely used for their strength and cost-effectiveness, with different coatings for corrosion resistance. Stainless steel offers excellent corrosion resistance and is preferred in outdoor or corrosive environments. Brass and copper washers are often used for their electrical conductivity and malleability, while aluminum is lightweight and corrosion-resistant. Beyond metals, non-metallic materials such as nylon, rubber, and fiber are also common. Nylon washers provide insulation, reduce friction, and are lightweight. Rubber washers are used for sealing and vibration damping, while fiber washers offer good insulation and are often used in plumbing. The choice of material depends on factors such as the required strength, corrosion resistance, electrical conductivity, temperature tolerance, and sealing capabilities for the intended application.

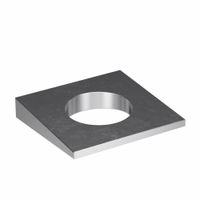

How do countersunk washers improve the appearance of a fastened surface?

Countersunk washers, also known as finishing washers, are designed to create a flush or slightly recessed surface when used with countersunk screws. They improve the appearance of a fastened surface in several ways:

Firstly, they provide a clean, finished look by allowing the screw head to sit level with or below the surface of the material. This eliminates the protrusion of the screw head, which can be visually unappealing and potentially snag on clothing or other objects.

Secondly, they distribute the clamping force of the screw over a wider area, which can prevent damage to softer materials and provide a more stable and aesthetically pleasing connection.

Thirdly, they can conceal any minor imperfections in the countersink hole, such as slight chipping or unevenness, by providing a smooth, uniform surface around the screw.

Finally, countersunk washers are often made from decorative materials like brass or stainless steel, or can be finished to match the surrounding material, further enhancing the overall visual appeal of the assembly. This makes them a popular choice in applications where aesthetics are important, such as in furniture, cabinetry, and architectural finishes.

What are the benefits of using a lock washer?

Lock washers are designed to prevent nuts and bolts from loosening due to vibration, thermal expansion, and other factors that can cause fasteners to lose preload. They achieve this by creating friction, increasing the resistance to rotation, or physically locking the fastener in place.

One common type is the split lock washer, which has a helical shape that flattens under torque, providing spring tension that helps maintain clamping force. This spring action also helps to compensate for minor settling or wear in the joint. Another type is the external tooth lock washer, which has serrations that bite into both the bearing surface of the fastener and the material it's fastening, creating a strong anti-rotation lock. Internal tooth lock washers work similarly but are designed for smaller heads.

Lock washers are particularly beneficial in applications where vibration is present, such as in machinery, vehicles, and structures. They enhance the reliability and safety of assemblies by ensuring that connections remain secure over time, reducing the risk of component failure or detachment. While they add a component to the assembly process, their role in maintaining joint integrity often outweighs this minor complexity, especially in critical applications.

How do washers prevent damage to materials?

Washers prevent damage to materials by distributing the load of a fastener over a larger surface area. This reduces the pressure at any single point, which can prevent indentation, crushing, or scratching of the material being fastened. They also provide a smooth bearing surface for the fastener, which can prevent galling or binding, especially with softer materials. In some applications, washers can also act as a spacer, preventing contact between different materials or allowing for proper clearance. Additionally, certain types of washers, like lock washers, help prevent loosening of fasteners due to vibration, which indirectly protects the materials by maintaining the integrity of the connection.

What is the difference between a flat washer and a sealing washer?

A flat washer, also known as a plain washer, is a simple, flat disc with a central hole. Its primary function is to distribute the load of a threaded fastener (like a bolt or screw) evenly over a larger area, preventing damage to the material being fastened and providing a smooth bearing surface. They also help to prevent loosening of the fastener due to vibration by providing a larger friction surface. Flat washers are typically made from various materials, including steel, stainless steel, brass, and plastic, and come in a wide range of sizes to suit different fastener dimensions. They do not provide any sealing capabilities.

A sealing washer, in contrast, is designed specifically to create a seal against the leakage of fluids or gases. These washers typically combine a metal washer with a resilient sealing material, such as rubber, neoprene, or EPDM. The metal part provides the structural integrity and load distribution, while the softer material deforms under compression to fill any gaps between the fastener and the mating surface, thus preventing leaks. Common types include bonded sealing washers (where the rubber is bonded to the metal) and self-sealing washers. Sealing washers are crucial in applications where maintaining a hermetic seal is critical, such as in plumbing, hydraulic systems, or automotive engines.

How do you choose the right size washer for a bolt or screw?

When choosing the right size washer for a bolt or screw, you need to consider two main dimensions: the inner diameter and the outer diameter.

The inner diameter of the washer should be slightly larger than the diameter of the bolt or screw. This ensures that the washer fits over the fastener without being too loose, which could compromise its effectiveness. A snug fit is ideal to properly distribute the load and prevent the washer from moving excessively during installation or use.

The outer diameter of the washer determines the surface area over which the load is distributed. A larger outer diameter provides a greater bearing surface, which is beneficial when fastening soft materials or when you need to spread the clamping force over a wider area to prevent damage or pull-through. Conversely, a smaller outer diameter might be chosen for aesthetic reasons or when space is limited.

In addition to the inner and outer diameters, consider the washer's thickness. Thicker washers offer more rigidity and can be used to add more load-bearing capacity. The type of washer (e.g., flat, lock, fender) also plays a role, as each type serves a specific purpose in an assembly. Always refer to industry standards and the fastener manufacturer's recommendations for precise sizing and application guidelines.

Can washers be reused after disassembly?

Generally, the reusability of washers after disassembly depends on their type, material, and the application's specific requirements. Flat washers, especially those made of durable metals like steel or stainless steel, can often be reused if they are not deformed, corroded, or excessively worn. Their primary function is to distribute the load and prevent damage to the mating surface, and if they still perform this function effectively, reinstallation is typically acceptable.

However, certain types of washers are designed for single use or have properties that are compromised upon disassembly. For instance, lock washers, such as split-ring, star, or spring washers, rely on their spring action or biting edges to create friction and prevent loosening. If these are flattened, deformed, or their gripping features are dulled during disassembly, their ability to maintain tension is significantly reduced, making reuse unadvisable for critical applications. Sealing washers, often made of softer materials like rubber, nylon, or copper, are designed to deform and create a tight seal. Once compressed, they lose their ability to form an effective seal if reused, which could lead to leaks or a loss of pressure.

In high-stress, high-vibration, or critical safety applications, it is generally recommended to replace all washers, regardless of type, during reassembly to ensure optimal performance and safety. When in doubt, consulting the manufacturer's guidelines for the specific components is the best practice.