Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are threaded inserts used for?

Please tell me what topic you would like me to elaborate on.

How do you repair stripped threads with a threaded insert?

To repair stripped threads with a threaded insert, you'll generally follow these steps:1. **Drill out the damaged threads:** Use a drill bit of the appropriate size (usually specified by the insert manufacturer) to remove the stripped material. Ensure the hole is straight and perpendicular to the surface.

2. **Tap the new hole:** Use a tap (also specified by the insert manufacturer) to cut new threads into the drilled hole. These new threads will be larger than the original stripped threads and are designed to accept the insert.

3. **Install the threaded insert:** Screw the threaded insert into the newly tapped hole. Some inserts require a special installation tool, while others can be installed with a standard screwdriver or Allen key.

4. **Break off the tang (if applicable):** Some inserts, like Heli-Coil inserts, have a tang that needs to be broken off after installation to allow the original bolt to pass through.This method creates a strong and durable repair, often stronger than the original threads. It's crucial to use the correct drill bit and tap sizes, as well as the appropriate insert for the material and application.

What is the difference between helical inserts and self-locking inserts?

Helical inserts, also known as wire thread inserts or coil inserts, are designed to repair or create strong internal threads in softer materials like aluminum, magnesium, and plastics. They are typically made from cold-rolled stainless steel wire and are coiled into a helical shape. When installed, they provide a durable, corrosion-resistant thread that can withstand high stress and vibration.

Self-locking inserts, on the other hand, are designed to provide a secure and vibration-resistant thread without the need for additional locking devices like lock washers or thread-locking adhesives. There are various types of self-locking inserts, but they generally incorporate a feature that creates interference with the mating fastener. This can be achieved through a modified thread form, a locking element (like a patch or a pellet), or a specialized design that creates a prevailing torque. The primary difference lies in their function: helical inserts are primarily for thread repair and reinforcement, while self-locking inserts are specifically engineered to prevent fasteners from loosening due to vibration or dynamic loads.

How do you install a rivet nut?

To install a rivet nut, first drill a hole of the appropriate size for the rivet nut into the material. Insert the rivet nut into the hole. Then, use a rivet nut tool, which typically has a threaded mandrel, to engage the threads of the rivet nut. Squeeze the handles of the tool (or activate the tool if it's pneumatic or electric) to compress the body of the rivet nut, causing it to expand and grip the material from the backside. Once the rivet nut is securely flared, remove the tool by unscrewing or disengaging the mandrel. The installed rivet nut then provides a strong, permanent threaded insert in the material, ready to accept a screw or bolt.

Can threaded inserts convert between standard and metric fasteners?

No, threaded inserts cannot convert between standard and metric fasteners. Threaded inserts are designed to provide strong, reusable threads in softer materials or to repair damaged threads. They are manufactured to a specific thread standard (either standard/inch or metric) and size. Using an insert meant for a standard fastener with a metric fastener, or vice-versa, would result in an improper fit, potential damage to the threads, and a compromised connection that could fail under load. To properly secure a fastener of a different standard, you would need to either use an adapter specifically designed for that conversion (if available for your specific application) or re-tap the hole to the desired thread standard and size, which might involve drilling out the existing hole first, depending on the difference in size and thread type.

What are the advantages of using self-tapping inserts?

Self-tapping inserts offer several advantages, particularly in applications requiring strong, wear-resistant threads in softer materials. One key benefit is their ability to create their own threads during installation, eliminating the need for a separate tapping operation. This saves time and reduces manufacturing costs. They also provide a secure, vibration-resistant fastening due to their robust design and typically larger external diameter compared to the internal thread. This makes them ideal for materials like plastics, composites, and light alloys where direct tapping might result in weaker threads. Furthermore, self-tapping inserts can repair damaged or worn-out threads, extending the lifespan of components. They also offer excellent resistance to pull-out and torque-out, ensuring a reliable connection.

How do you install a heat-set insert?

To install a heat-set insert, you will need a soldering iron or a specialized heat-set insert installation tip. Place the insert into the hole you've prepared, ensuring it's oriented correctly. Then, apply heat to the insert using your soldering iron or heat-set tip. As the insert heats up, it will melt the surrounding plastic, allowing the insert to sink into the material. Apply gentle, steady pressure to guide the insert until it is flush or slightly below the surface of the part. Once the insert is in place, remove the heat and allow the plastic to cool and solidify around the insert, securely embedding it. Ensure the hole size is appropriate for the insert to allow for proper melting and a secure fit.

What is the purpose of a weld nut?

A weld nut is a specialized nut designed to be permanently attached to another component by welding. Its primary purpose is to create a strong, secure, and permanent threaded connection point on a metal surface, particularly in situations where it's impractical or impossible to tap a hole directly into the material.

Weld nuts are commonly used in various industries, including automotive, manufacturing, and construction, to provide attachment points for fasteners. They come in different types, such as square, hex, and round base, each suited for specific welding processes and applications. The projection on the nut, or the design of its base, is engineered to facilitate proper alignment and create a strong weld joint, ensuring the nut remains firmly in place even under significant stress or vibration.

How do T-nuts work in wood applications?

T-nuts are fasteners used to provide a strong, threaded insert in wood, particle board, or composite materials. They have a flange at one end and a threaded barrel at the other, with prongs or barbs extending from the flange. To install, a hole is drilled into the wood, and the T-nut is hammered or pressed into the hole. The prongs bite into the wood, preventing the T-nut from rotating when a bolt is tightened into it. This creates a secure, flush mounting point that can withstand repeated assembly and disassembly without stripping the wood, making them ideal for furniture, speaker cabinets, and climbing holds.

What are the benefits of using socket nuts as inserts?

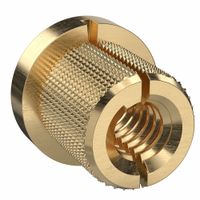

Socket nuts, when used as inserts, offer several key benefits that enhance the strength and durability of assemblies. One significant advantage is their ability to provide a robust, reusable thread in materials that are typically too soft or brittle for direct tapping, such as plastics, composites, or soft metals. This eliminates the risk of thread stripping, which is common in these materials, and allows for repeated assembly and disassembly without compromising the integrity of the connection.

Additionally, socket nuts distribute the load over a larger surface area compared to traditional fasteners, which reduces stress concentration and prevents material deformation or cracking around the joint. This is particularly crucial in applications where vibration or dynamic loads are present, as it contributes to a more stable and long-lasting connection. Their design often includes features like knurling or self-tapping threads, which ensure a secure and permanent installation within the host material, resisting pull-out and torque-out forces. This reliability makes them ideal for critical applications where joint failure could lead to significant issues.