Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are the different types of nuts used in fastening?

Nuts are essential components in fastening, designed to be paired with a bolt or threaded rod to secure two or more parts together. They come in various types, each suited for specific applications and offering unique advantages.

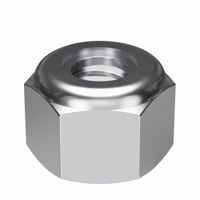

Hex nuts are the most common type, featuring a hexagonal shape that allows for easy tightening with a wrench. They are widely used in general fastening applications due to their versatility and availability.

Lock nuts, also known as prevailing torque nuts, are designed to resist loosening due to vibration and torque. This is often achieved through a nylon insert (nyloc nut) or a distorted thread design, creating friction against the bolt threads. They are ideal for applications where fasteners are subjected to dynamic loads, such as in automotive or machinery assemblies.

Wing nuts have "wings" on either side, allowing them to be tightened or loosened by hand without the need for tools. They are convenient for applications requiring frequent adjustments or quick assembly and disassembly, like in temporary fixtures or furniture.

Cap nuts, or acorn nuts, have a domed top that covers the exposed bolt threads, providing a finished look and protecting against snagging or injury. They are often used for aesthetic purposes or to prevent damage to electrical wiring.

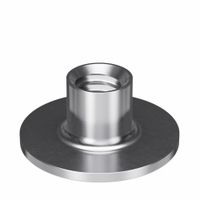

Flange nuts feature a wide flange at one end that acts as an integrated washer, distributing the load over a larger area and preventing damage to the material being fastened. This design also helps to reduce the need for a separate washer, simplifying assembly.

Coupling nuts are elongated nuts used to connect two threaded rods or to extend the length of a threaded assembly. They have internal threads at both ends and are useful for joining components in long-span structures or where precise alignment is required.

These are just a few examples, and the choice of nut depends on factors such as the application's environment, required strength, vibration resistance, and aesthetic considerations.

How do hex nuts differ from lock nuts?

Hex nuts are standard, six-sided fasteners designed to be tightened with a wrench, providing a basic threaded connection. They are widely used in general applications where vibration or loosening is not a significant concern. Lock nuts, on the other hand, are specifically engineered to resist loosening due to vibration, torque, or pressure. They incorporate various mechanisms to create friction or interference with the bolt threads, preventing accidental unscrewing. Common types of lock nuts include nylon insert lock nuts (Nyloc nuts), which have a polymer insert that grips the bolt threads, and all-metal prevailing torque lock nuts, which deform the threads to create a tight fit. While hex nuts are simpler and more economical, lock nuts offer enhanced security in critical applications where fastener integrity is paramount.

What is the purpose of a cap nut?

A cap nut, also known as a dome nut, acorn nut, or crown nut, is a specialized type of nut that has a domed or spherical top. Its primary purpose is to cover and protect the exposed threads of a bolt or screw. This not only provides a more aesthetically pleasing finish by hiding unsightly threads but also offers several practical benefits.

Firstly, the cap acts as a protective barrier, preventing damage to the bolt's threads from environmental factors such as moisture, dirt, and corrosion, which can extend the lifespan of the fastener. Secondly, it enhances safety by covering sharp or protruding thread ends, reducing the risk of injuries from accidental contact. This is particularly useful in applications where parts are frequently handled or in areas accessible to the public. Thirdly, the cap nut can provide a more secure connection by preventing snagging or catching on clothing or other objects, which might inadvertently loosen or damage the assembly. Finally, in certain applications, the sealed end of a cap nut can help to prevent the leakage of fluids or gases if the fastener is part of a sealed system.

How do you install a flange nut without damaging the surface?

When installing a flange nut, it's crucial to prevent surface damage, especially on delicate finishes or soft materials. Here are some strategies:1. Use a torque wrench: This ensures the nut is tightened to the manufacturer's specified torque, preventing overtightening which can deform the surface or strip threads.

2. Employ a socket wrench with a protective insert: Some sockets come with plastic or rubber inserts designed to cushion the nut and prevent direct metal-on-metal contact with the surface.

3. Place a washer or protector: A nylon, rubber, or soft metal washer between the flange nut and the surface can distribute the clamping force and absorb pressure, preventing marring.

4. Apply a non-marring coating or tape: For extremely sensitive surfaces, a layer of painter's tape or a non-marring film can be applied to the surface before installation.

5. Lubricate threads (if appropriate): For some applications, a small amount of thread lubricant can reduce friction, allowing for smoother tightening and preventing the nut from binding and digging into the surface. However, be cautious as lubrication can affect torque readings, so always consult manufacturer guidelines.

6. Use a proper fitting tool: Ensure your wrench or socket is the correct size to prevent slippage, which can scratch the surface or round off the nut's corners.By following these precautions, you can install flange nuts securely without compromising the integrity or appearance of the surrounding material.

What are coupling nuts used for?

Coupling nuts are internally threaded fasteners used to join two male threads, most commonly threaded rods or pipes. They are typically hexagonal, allowing for tightening with a wrench, and are longer than standard nuts to provide sufficient thread engagement for both connected pieces. Their primary function is to extend the length of an assembly, repair damaged threads, or join multiple components in a secure and aligned manner. They are widely used in construction, plumbing, and industrial applications where reliable and sturdy connections are essential.

How do cage nuts and spring nuts differ in installation?

Cage nuts and spring nuts are both used for mounting equipment in server racks, but their installation methods differ significantly, making each suitable for specific scenarios.

Cage nuts are designed for square-holed rack rails. Installation involves compressing the "wings" of the nut and inserting them into the square hole. Once the wings are released, they expand, securing the nut in place. This method provides a strong, secure, and permanent-feeling anchor point. They are generally preferred for heavy equipment due to their robust hold. However, installing or repositioning cage nuts can be more time-consuming and require a specific tool or a bit of dexterity, especially in tight spaces.

Spring nuts, on the other hand, are typically used with threaded rack rails (often found in older rack designs or specific equipment). They feature a spring-loaded mechanism that holds the nut in place against the rack rail. Installation is much simpler: the nut is merely pushed into the rail until the spring engages, keeping it from falling out while the screw is inserted. This makes spring nuts quicker to install and reposition, offering greater flexibility when frequently reconfiguring rack setups. However, their holding power might be less robust than cage nuts, making them more suitable for lighter equipment or applications where quick adjustments are paramount.

In summary, the choice between cage nuts and spring nuts largely depends on the rack rail type, the weight of the equipment, and the desired ease of installation and repositioning.

What are the advantages of using square nuts?

Square nuts offer several advantages due to their design. Their four flat sides provide a larger surface area for wrenches, making them easier to grip and tighten, especially in applications where space is limited or where quick assembly is necessary. This design also contributes to better torque distribution, reducing the likelihood of stripping the nut or rounding the corners during installation.

Another significant benefit is their increased resistance to loosening due to vibration. The larger bearing surface and the ability to bite into the material provide a more secure connection compared to hexagonal nuts in certain scenarios. This makes them particularly suitable for applications in machinery, vehicles, or structures that experience significant movement or stress.

Furthermore, square nuts are often preferred in channels or slots where they can be held in place, preventing rotation while the bolt is tightened. This can simplify assembly and allow for one-handed tightening, improving efficiency in manufacturing and construction. Their robust construction also makes them durable and less prone to deformation under heavy loads, ensuring a reliable and long-lasting fastening solution.

How are weld nuts installed?

Weld nuts are specialized fasteners designed to be permanently attached to another component, typically a metal sheet or plate, through a welding process. This creates a strong, durable, and internally threaded connection point for bolts or other threaded fasteners.

There are several methods for installing weld nuts, but the most common involve projection welding or resistance welding. In projection welding, small protrusions (projections) on the nut are melted and fused with the parent material under pressure and current. This method is highly efficient for high-volume production.

The installation process generally involves:1. **Preparation**: The parts to be welded are cleaned to ensure good electrical contact and prevent contamination.

2. **Positioning**: The weld nut is precisely positioned against the component where the threaded hole is desired. Fixtures or tooling are often used to maintain accurate alignment.

3. **Welding**: A welding machine delivers a controlled electrical current and pressure to the nut and the component. The projections on the nut create concentrated heat points, causing the metal to melt and fuse.

4. **Cooling**: After the current is stopped, the weld cools and solidifies, creating a permanent bond.The specific type of weld nut (e.g., round base, square base, tab base) and the application will dictate the exact welding parameters and equipment used. Properly installed weld nuts provide excellent torque resistance and pull-out strength, making them ideal for applications requiring robust threaded connections.

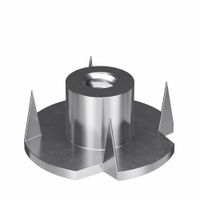

What is the function of T-nuts in woodworking?

T-nuts are threaded fasteners used in woodworking to create a strong, reusable, and flush threaded insert in wood or other soft materials. They are typically hammered or pressed into a pre-drilled hole from one side of the workpiece, with a flange that sits flush with the surface. The prongs on the T-nut bite into the wood, preventing it from rotating when a bolt or screw is threaded into it. This allows for repeated assembly and disassembly without stripping the wood fibers, making them ideal for applications where components need to be easily removed or adjusted, such as knockdown furniture, jigs, fixtures, and speaker cabinets. They provide a more durable and reliable connection than simply threading screws directly into wood, which can weaken over time with repeated use.

How do you choose the right nut for a specific application?

Choosing the right nut for a specific application involves considering several factors to ensure proper fastening, durability, and safety. First, consider the load and stress requirements. For applications with high tensile loads or vibrations, self-locking nuts (like nyloc nuts or prevailing torque nuts) or castle nuts with cotter pins are ideal to prevent loosening. For lighter loads, standard hex nuts might suffice.

Second, the material of the nut should be compatible with the bolt and the surrounding environment. Common materials include steel (various grades like plain, galvanized, or stainless), brass, and nylon. Stainless steel offers excellent corrosion resistance, making it suitable for outdoor or marine applications. Brass is often used for its aesthetic appeal and conductivity. Nylon nuts are lightweight and offer good electrical insulation.

Third, consider the type of thread. Most nuts use standard unified (UNC or UNF) or metric (coarse or fine) threads, which must match the bolt’s threading. Fine threads offer a stronger connection and finer adjustment but are more susceptible to stripping.

Fourth, the application’s environment plays a crucial role. For high-temperature environments, specialized high-temperature nuts made from alloys like Inconel are necessary. In corrosive environments, nuts with appropriate coatings or materials are essential.

Finally, consider ease of installation and removal. Wing nuts or knurled nuts are useful for hand-tightening applications where frequent adjustments are needed. Flange nuts distribute the load over a larger area, reducing the need for a washer. By carefully evaluating these factors, you can select the most appropriate nut for your specific needs.