Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What is the purpose of a key in a mechanical system?

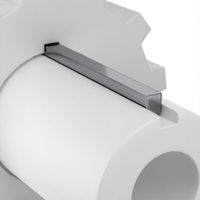

In a mechanical system, a key is a machine element used to connect a rotating machine element to a shaft. The key is inserted into a keyway, a slot or groove machined into both the shaft and the rotating element (such as a gear, pulley, or coupling). This creates a positive mechanical lock, preventing relative rotation between the two components.

The primary purpose of a key is to transmit torque from the shaft to the rotating element, or vice versa. When the shaft rotates, the key presses against the sides of the keyway in both the shaft and the rotating element, transferring the rotational force. This ensures that the two parts rotate together as a single unit.

Keys also serve to maintain the axial position of the rotating element on the shaft, preventing it from sliding along the shaft. There are various types of keys, including square keys, rectangular keys, round keys, and taper keys, each designed for specific applications and torque requirements. The selection of a particular key type depends on factors such as the amount of torque to be transmitted, the precision required, and the ease of assembly and disassembly.

How do you choose the right key stock size?

Choosing the right key stock size is crucial for ensuring a secure and efficient connection between a shaft and a rotating component like a gear or pulley. The primary consideration is the shaft diameter. A commonly used guideline suggests that the key width should be approximately one-quarter of the shaft diameter. For instance, a 1-inch diameter shaft would typically use a 1/4-inch wide key.

Beyond this general rule, several factors influence the final decision. The amount of torque being transmitted is critical; higher torque applications may require larger keys or multiple keys to prevent shearing. The material of both the shaft and the key also plays a role. Stronger materials can handle more stress, potentially allowing for slightly smaller keys.

Consider the operating environment and any specific industry standards or codes that might apply. These can dictate key dimensions, tolerances, and materials. Also, evaluate the available space within the hub for the keyway and the ease of manufacturing. Ultimately, precise calculations, often involving engineering principles and material properties, are used to determine the optimal key stock size for a given application to ensure reliable power transmission and prevent failure.

What materials are commonly used for key stock?

Key stock is typically made from various materials, each offering different properties suitable for specific applications. Common materials include carbon steel, stainless steel, and alloy steel. Carbon steel is a popular choice due to its strength and cost-effectiveness, often used in general machinery. Stainless steel is preferred in environments requiring corrosion resistance, such as food processing or marine applications, due to its chromium content. Alloy steel, which contains other elements like nickel, chromium, or molybdenum, offers enhanced strength, hardness, and wear resistance, making it suitable for heavy-duty or high-stress applications. Other less common materials might include brass or aluminum for lighter loads or specific non-magnetic requirements. The selection of key stock material depends on factors such as the required load capacity, operating environment, and cost considerations.

How do you install a machine key?

Please tell me what topic you would like me to elaborate on.

What are the different types of machine keys?

Machine keys are mechanical components used to prevent relative rotation between a shaft and a rotating machine element like a gear or pulley. They are typically placed in a keyway, which is a groove cut into both the shaft and the rotating element.

Some common types of machine keys include: * **Sunk Keys:** These keys are fitted into keyways cut in both the shaft and the hub. They are the most common type and offer good torque transmission. Examples include:

* **Square and Rectangular Keys:** These have a square or rectangular cross-section.

* **Parallel Sunk Keys:** These have a uniform cross-section throughout their length.

* **Taper Sunk Keys:** These have a slight taper to provide a tight fit.

* **Gib-Head Keys:** These are tapered keys with a head on one end for easy removal.

* **Woodruff Keys:** These are semi-circular keys that fit into a circular keyway in the shaft and a rectangular keyway in the hub. They are self-aligning and good for applications with slight misalignment.

* **Saddle Keys:** These keys are tapered and fit into a keyway in the hub only, with the bottom surface bearing directly on the shaft. They are suitable for light-duty applications as they rely on friction for torque transmission.

* **Flat Keys:** Similar to saddle keys, these are flat and fit into a keyway in the hub, resting on a flattened surface on the shaft. They also rely on friction.

* **Round Keys (Pin Keys):** These are circular pins that fit into holes drilled partially in the shaft and partially in the hub. They are often used for light loads or for positioning.The choice of key type depends on the amount of torque to be transmitted, the operating conditions, and the ease of assembly and disassembly required.

How do you measure a keyway?

A keyway is a slot or groove machined into a shaft or hub to accommodate a key, which prevents relative rotation between the parts. Measuring a keyway accurately is crucial for proper fit and function.

To measure a keyway, you typically need to determine its width, depth, and sometimes its length.1. **Width:** Use a caliper or micrometer to measure the width of the keyway. This is the dimension across the opening of the slot. Take multiple measurements along the length to ensure consistency.

2. **Depth:** This can be more challenging. For through keyways (those that go all the way through the material), you can measure from the opposite side of the shaft or hub to the bottom of the keyway. For blind keyways (those that don't go all the way through), you'll need a depth micrometer or a small rule. Measure from the surface of the shaft or hub to the deepest point of the keyway.

3. **Length:** Measure the overall length of the keyway along the shaft or hub. This is typically done with a ruler or caliper.It's important to use appropriate measuring tools and ensure they are calibrated for accurate results. The specific method may vary slightly depending on the type of keyway (e.g., straight, tapered, Woodruff) and the part it's in.

What is the difference between a machine key and key stock?

A machine key is a pre-cut, standardized component designed to fit into a keyway, which is a slot or groove in a shaft and a mating component (like a pulley or gear). Its primary purpose is to transmit torque and prevent relative rotation between these parts. Machine keys come in various shapes and sizes, such as square, rectangular, or gib head, and are manufactured to specific tolerances for a precise fit.

Key stock, on the other hand, is a raw, unmachined bar of material (typically steel or stainless steel) with a consistent cross-sectional shape, often square or rectangular. It is sold in longer lengths, and users cut it to the desired size and shape to create custom keys. Key stock offers flexibility for applications where standard machine keys may not be suitable or for prototyping. While both relate to keys for transmitting torque, a machine key is a finished product ready for installation, whereas key stock is the raw material from which keys can be fabricated.

How do you cut key stock to the correct length?

Please tell me what you would like me to elaborate on.

What are the common applications of machine keys?

Machine keys are essential components in mechanical engineering, primarily used to transmit torque between a shaft and a rotating machine element like a gear, pulley, or coupling. They prevent relative rotation between the shaft and the attached component. Common applications include: * **Electric Motors:** Keys are used to connect the motor shaft to the pulley or gear that drives a machine.

* **Pumps:** They connect the pump impeller to the motor or engine shaft, ensuring efficient fluid movement.

* **Gearboxes:** Keys are crucial for connecting gears to their respective shafts within a gearbox, enabling power transmission and speed changes.

* **Machine Tools:** Lathes, milling machines, and drills utilize keys to secure cutting tools or work-holding devices to the machine's rotating shafts.

* **Conveyor Systems:** Keys connect the drive sprockets or pulleys to the motor shafts, facilitating the movement of materials.

* **Agricultural Machinery:** Tractors, harvesters, and other farm equipment use keys in various power transmission assemblies.

* **Automotive Industry:** Keys are found in applications like securing flywheels to crankshafts or connecting transmission components.In essence, wherever a rotating component needs to be rigidly connected to a shaft for torque transmission, machine keys provide a simple yet robust solution.

How do you prevent keyway failure?

Preventing keyway failure involves several design and maintenance considerations. Proper sizing of the key and keyway is crucial, ensuring the key is strong enough to transmit the required torque without deforming or shearing. Material selection also plays a significant role; using a key and shaft material with appropriate strength and hardness for the application can increase durability. Additionally, the fit between the key and keyway should be precise to avoid excessive play, which can lead to fretting and wear. Stress concentrations can be reduced by designing keyways with generous radii at the corners rather than sharp edges. Regular inspection for signs of wear, corrosion, or fatigue, and timely replacement of worn components, are essential for long-term reliability. Proper lubrication can also reduce friction and wear within the keyway.