Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electronics Batteries

- Electronic Communication Equipment

- Data Entry Devices Accessories

.....Read More

Frequently Asked Questions

What are the different types of data entry devices used in industrial areas?

In industrial areas, various data entry devices are utilized to enhance efficiency, accuracy, and productivity. These devices include:

1. **Barcode Scanners**: Used for inventory management and tracking, barcode scanners quickly read and input data from barcodes on products or components.

2. **RFID Readers**: Radio Frequency Identification (RFID) readers capture data from RFID tags attached to items, allowing for real-time tracking and management of assets and inventory.

3. **Touchscreen Terminals**: These are used for inputting data directly into systems, often found in manufacturing lines for operators to enter production data or quality control information.

4. **Keyboards**: Standard or industrial-grade keyboards are used for manual data entry, often in conjunction with other devices for entering detailed information.

5. **Voice Recognition Systems**: These systems allow workers to input data hands-free, which is particularly useful in environments where manual entry is impractical.

6. **Magnetic Stripe Readers**: Used for reading data encoded in magnetic stripes, often found on employee ID cards or access control systems.

7. **Optical Character Recognition (OCR) Devices**: OCR devices convert different types of documents, such as scanned paper documents or PDFs, into editable and searchable data.

8. **Handheld Computers**: Rugged handheld devices are used for data collection in the field, often equipped with barcode scanners and wireless connectivity.

9. **Tablets and Mobile Devices**: These are increasingly used for data entry due to their portability and ease of use, often equipped with custom industrial applications.

10. **Digital Pens**: Used to capture handwritten data and convert it into digital form, useful in environments where traditional data entry is challenging.

These devices are integral to streamlining operations, reducing errors, and improving data accuracy in industrial settings.

How do keyboards and keypads enhance security in industrial facilities?

Keyboards and keypads enhance security in industrial facilities by providing controlled access, authentication, and data protection. They serve as the first line of defense by requiring authorized personnel to input specific codes or credentials to gain entry to restricted areas, ensuring that only those with the correct information can access sensitive zones. This reduces the risk of unauthorized entry and potential security breaches.

Keypads often integrate with access control systems, allowing for real-time monitoring and logging of entry attempts. This capability enables facility managers to track who enters and exits specific areas, providing an audit trail that can be crucial for investigating security incidents. Additionally, these systems can be programmed to trigger alarms or notifications if incorrect codes are entered multiple times, alerting security personnel to potential threats.

In environments where biometric systems might be impractical due to dirt or harsh conditions, keypads offer a reliable alternative. They can be designed to withstand extreme temperatures, moisture, and physical abuse, ensuring consistent performance in challenging industrial settings.

Moreover, keyboards and keypads can be used to secure digital systems within the facility. By requiring password entry for access to computers and control systems, they help protect sensitive data and operational controls from cyber threats. This is particularly important in industrial facilities where the compromise of digital systems could lead to significant operational disruptions or safety hazards.

Overall, keyboards and keypads provide a versatile and robust security solution, enhancing both physical and digital security measures in industrial facilities.

What are the key features to look for in industrial data entry devices?

When selecting industrial data entry devices, consider the following key features:

1. **Durability and Ruggedness**: Devices should withstand harsh environments, including exposure to dust, moisture, and extreme temperatures. Look for IP ratings and MIL-STD certifications.

2. **Ergonomics and Design**: Ensure the device is comfortable for prolonged use, with an intuitive interface and design that minimizes user fatigue.

3. **Data Input Options**: Consider devices with multiple input methods such as touchscreens, physical keyboards, and stylus support to accommodate different user preferences and tasks.

4. **Connectivity**: Robust connectivity options like Wi-Fi, Bluetooth, and cellular capabilities are essential for real-time data transfer and communication.

5. **Battery Life**: Long-lasting battery life is crucial for uninterrupted operation, especially in remote or field locations. Look for devices with quick charging and replaceable batteries.

6. **Processing Power and Storage**: Adequate processing power and storage capacity are necessary to handle complex applications and large datasets efficiently.

7. **Software Compatibility**: Ensure compatibility with existing enterprise software and systems for seamless integration and data management.

8. **Security Features**: Data security is paramount. Look for devices with encryption, biometric authentication, and secure boot features.

9. **Display Quality**: A clear, high-resolution display that is readable in various lighting conditions, including direct sunlight, is important for accurate data entry.

10. **Support and Warranty**: Reliable customer support and a comprehensive warranty can minimize downtime and ensure quick resolution of any issues.

11. **Cost-effectiveness**: Balance the initial investment with long-term benefits, considering total cost of ownership, including maintenance and potential upgrades.

12. **Scalability and Flexibility**: Devices should be adaptable to future technological advancements and scalable to meet growing business needs.

How do you maintain and clean industrial keyboards and keypads?

To maintain and clean industrial keyboards and keypads, follow these steps:

1. **Power Down**: Ensure the device is turned off and unplugged to prevent electrical hazards.

2. **Initial Dust Removal**: Use a can of compressed air to blow away loose dust and debris from the surface and between the keys.

3. **Surface Cleaning**: Dampen a microfiber cloth with a mild cleaning solution (water mixed with a small amount of isopropyl alcohol). Wipe the surface of the keyboard and keys gently. Avoid excessive moisture to prevent liquid from seeping into the device.

4. **Deep Cleaning**: For stubborn grime, use cotton swabs dipped in the cleaning solution to reach tight spaces around the keys. Ensure the swabs are not overly wet.

5. **Disinfecting**: Use disinfectant wipes or a cloth with a diluted bleach solution (1 part bleach to 10 parts water) to sanitize the keyboard, especially in shared environments. Ensure the solution is safe for the keyboard material.

6. **Key Removal (if applicable)**: For thorough cleaning, remove keys if the design allows. Use a keycap puller to avoid damage. Clean the keys individually and the exposed keyboard surface.

7. **Drying**: Allow the keyboard to air dry completely before reassembling and reconnecting it to power.

8. **Regular Maintenance**: Implement a regular cleaning schedule based on the usage environment. In dusty or greasy settings, more frequent cleaning may be necessary.

9. **Protective Covers**: Consider using protective covers to minimize dirt accumulation and simplify cleaning.

10. **Inspection**: Regularly inspect for wear and tear, and replace damaged keys or components to ensure optimal functionality.

By following these steps, you can maintain the hygiene and performance of industrial keyboards and keypads effectively.

What are the common replacement parts for data entry devices?

Common replacement parts for data entry devices include:

1. **Keyboards:**

- **Keys/Switches:** Individual keys or switches can wear out or become unresponsive.

- **Keycaps:** These can become worn or damaged and may need replacement.

- **Membrane Sheets:** In membrane keyboards, the sheets can degrade over time.

- **Cables/Connectors:** USB or PS/2 cables can become frayed or damaged.

2. **Mice:**

- **Buttons/Switches:** The left and right click buttons can wear out.

- **Scroll Wheel:** The wheel can become unresponsive or sticky.

- **Sensors:** Optical or laser sensors can fail, affecting tracking.

- **Feet/Gliders:** These can wear down, affecting movement.

3. **Touchpads:**

- **Surface:** The touch-sensitive surface can become less responsive.

- **Cables/Connectors:** Internal connections can become loose or damaged.

4. **Scanners:**

- **Glass/Platen:** The scanning surface can get scratched or dirty.

- **Bulbs/LEDs:** Light sources can burn out or degrade.

- **Belts/Motors:** These can wear out, affecting the movement of the scanning head.

5. **Barcode Scanners:**

- **Laser/LED Modules:** These can fail, affecting scanning capability.

- **Trigger/Button:** The trigger mechanism can wear out.

- **Cables/Connectors:** Wired connections can become damaged.

6. **Digital Pens:**

- **Tips/Nibs:** These can wear down with use.

- **Batteries:** Rechargeable or replaceable batteries may need replacement.

7. **Stylus for Touchscreens:**

- **Tips:** The tip can wear out or become less responsive.

- **Batteries:** Some styluses require battery replacements.

8. **Numeric Keypads:**

- **Keys/Switches:** Similar to keyboards, individual keys can fail.

- **Cables/Connectors:** Connections can become damaged or loose.

These components are essential for maintaining the functionality and efficiency of data entry devices.

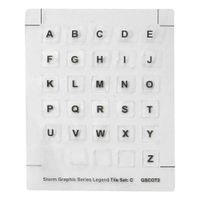

How do legend sets and keytops improve data entry device functionality?

Legend sets and keytops enhance data entry device functionality by improving user interaction, efficiency, and accuracy.

Legend sets, which are the symbols or characters printed on keys, provide clear visual cues that help users quickly identify the function of each key. This reduces the cognitive load on users, allowing them to focus on the task rather than remembering key functions. Well-designed legend sets can include color coding or grouping of related functions, further aiding in quick recognition and reducing errors.

Keytops, the physical surface of the keys, contribute to the tactile experience of data entry. Ergonomically designed keytops can improve comfort and reduce fatigue during extended use. Features such as concave or sculpted surfaces help users maintain finger positioning, enhancing typing speed and accuracy. Textured or coated keytops can also provide better grip, preventing slips and ensuring consistent input.

Together, legend sets and keytops facilitate a more intuitive and efficient user experience. They enable users to perform tasks with minimal training and adapt quickly to different devices. In specialized environments, such as data entry for specific industries, custom legend sets and keytops can be tailored to include industry-specific symbols or shortcuts, further optimizing workflow.

Overall, by enhancing visual and tactile feedback, legend sets and keytops play a crucial role in improving the functionality of data entry devices, leading to increased productivity and reduced error rates.

What are the best practices for installing and configuring industrial keypads?

1. **Site Assessment**: Evaluate the environment where the keypad will be installed. Consider factors like temperature, humidity, exposure to chemicals, and potential for physical damage.

2. **Selection of Keypad**: Choose a keypad designed for industrial use, ensuring it meets necessary standards (e.g., IP rating for dust and water resistance, NEMA rating for environmental conditions).

3. **Mounting Location**: Install the keypad at an ergonomic height and location for ease of use. Ensure it is accessible but protected from potential hazards.

4. **Wiring and Connectivity**: Use industrial-grade cables and connectors. Ensure proper shielding to prevent electromagnetic interference. Follow manufacturer guidelines for wiring to avoid damage and ensure functionality.

5. **Power Supply**: Ensure a stable and adequate power supply. Use surge protectors to safeguard against voltage spikes.

6. **Configuration**: Program the keypad according to operational needs. Set up user access levels and permissions. Ensure the keypad is integrated with existing systems, such as access control or machinery interfaces.

7. **Security Measures**: Implement security protocols, such as encryption for data transmission and regular updates to firmware to protect against vulnerabilities.

8. **Testing**: Conduct thorough testing to ensure all keys function correctly and the keypad communicates effectively with connected systems.

9. **Training**: Provide training for users on proper operation and troubleshooting. Ensure they understand the keypad’s features and limitations.

10. **Maintenance**: Establish a regular maintenance schedule. Inspect for wear and tear, clean the keypad to prevent buildup of dirt and debris, and check for software updates.

11. **Documentation**: Keep detailed records of installation, configuration settings, and maintenance activities for future reference and troubleshooting.