Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Industrial Controls Automation And Machine Safety

- Proximity Motion Vision Sensors

- Photoelectric Proximity Sensors

.....Read More

Frequently Asked Questions

What are the different types of photoelectric proximity sensors?

Photoelectric proximity sensors are categorized into three main types based on their operational principles:

1. **Through-Beam Sensors**: This type consists of a separate transmitter and receiver. The transmitter emits a light beam directly to the receiver. An object is detected when it interrupts the light beam. Through-beam sensors offer the longest sensing range and are highly reliable due to their direct light path, making them suitable for detecting opaque objects in various industrial applications.

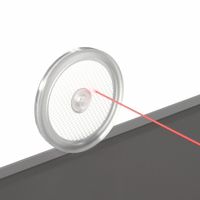

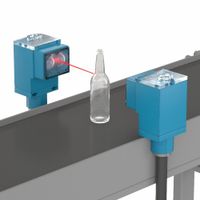

2. **Retro-Reflective Sensors**: These sensors have the transmitter and receiver housed in the same unit. They require a reflector placed opposite the sensor to bounce the emitted light back to the receiver. An object is detected when it breaks the light path between the sensor and the reflector. Retro-reflective sensors are easier to install than through-beam sensors and are effective for detecting transparent objects when using polarizing filters.

3. **Diffuse-Reflective Sensors**: In this type, the transmitter and receiver are also in the same unit. The sensor detects objects by emitting light that reflects off the object back to the receiver. The detection range is shorter compared to the other types, as it depends on the reflectivity of the object. Diffuse sensors are ideal for applications where the object’s surface is reflective enough to return sufficient light to the sensor.

Each type of photoelectric proximity sensor has its advantages and is chosen based on factors like the required sensing range, object material, environmental conditions, and installation constraints.

How do retroreflective photoelectric proximity sensors work?

Retroreflective photoelectric proximity sensors work by emitting a beam of light, typically infrared, from a light-emitting diode (LED) towards a specially designed reflector. The reflector is engineered to bounce the light back to the sensor regardless of the angle of incidence. The sensor has a photodetector that receives the reflected light.

In normal operation, the light travels from the sensor to the reflector and back, completing a light path. When an object interrupts this path, the sensor detects a reduction or absence of the reflected light. This change in light reception triggers the sensor to switch its output state, indicating the presence of an object.

These sensors are advantageous because they require only one device to be installed on one side of the detection area, with the reflector on the opposite side. This simplifies installation and alignment compared to through-beam sensors, which require both an emitter and a receiver on opposite sides.

Retroreflective sensors can detect objects regardless of their color or material, as long as they sufficiently interrupt the light path. However, they may struggle with transparent or highly reflective objects unless equipped with polarization filters. These filters ensure that only light with a specific polarization, altered by the reflector, is detected, reducing false readings from shiny surfaces.

Overall, retroreflective photoelectric proximity sensors are versatile, easy to install, and effective for various applications, including conveyor systems, packaging lines, and automated machinery.

What is the difference between diffuse and through-beam photoelectric sensors?

Diffuse photoelectric sensors detect objects by emitting a light beam that reflects off the object back to the sensor's receiver. The sensor and the receiver are housed in the same unit. The detection occurs when the object interrupts the light path, causing a change in the amount of light received. These sensors are suitable for detecting objects with varying shapes, sizes, and colors, but their range is limited and can be affected by the object's surface reflectivity.

Through-beam photoelectric sensors consist of two separate units: an emitter and a receiver. The emitter sends a continuous light beam directly to the receiver. An object is detected when it interrupts this beam, causing a drop in the light received. Through-beam sensors offer a longer detection range and higher reliability in challenging environments, as they are less affected by the object's color or surface. They are ideal for applications requiring precise detection and are often used in environments with dust, dirt, or other contaminants.

In summary, diffuse sensors are more compact and easier to install but have a shorter range and can be affected by the object's reflectivity. Through-beam sensors provide longer range and higher accuracy but require more space and alignment of separate emitter and receiver units.

How do fiber optic sensors function in photoelectric applications?

Fiber optic sensors function in photoelectric applications by utilizing the transmission of light through optical fibers to detect changes in environmental conditions. These sensors consist of a light source, optical fiber, and a photodetector. The light source emits light that travels through the optical fiber, which is a flexible, transparent fiber made of glass or plastic.

In photoelectric applications, fiber optic sensors operate based on the modulation of light properties such as intensity, phase, wavelength, or polarization. When the light travels through the fiber, any changes in the external environment, such as temperature, pressure, or strain, can alter these properties. The optical fiber acts as both the transmission medium and the sensing element.

The light that exits the fiber is captured by a photodetector, which converts the light signal into an electrical signal. This signal is then analyzed to determine the changes in the light properties, which correspond to the environmental changes being monitored.

Fiber optic sensors are highly sensitive and can be used in various applications, including industrial automation, environmental monitoring, and medical diagnostics. They offer advantages such as immunity to electromagnetic interference, high sensitivity, and the ability to function in harsh environments. Additionally, they can be used for remote sensing over long distances, as the light can travel through the fiber with minimal loss.

Overall, fiber optic sensors in photoelectric applications provide precise and reliable measurements by leveraging the unique properties of light and optical fibers.

What are the advantages of using photoelectric proximity sensors?

Photoelectric proximity sensors offer several advantages:

1. **Long Sensing Range**: They can detect objects over long distances, often up to several meters, which is significantly greater than other types of proximity sensors like inductive or capacitive sensors.

2. **Versatility**: These sensors can detect a wide range of materials, including metals, plastics, glass, and liquids, making them suitable for diverse applications.

3. **High Speed and Accuracy**: Photoelectric sensors provide fast response times and high accuracy, which is essential for applications requiring precise object detection and positioning.

4. **Non-contact Detection**: They operate without physical contact, reducing wear and tear and extending the sensor's lifespan.

5. **Variety of Models**: Available in different configurations such as through-beam, retro-reflective, and diffuse-reflective, allowing for flexibility in installation and application.

6. **Environmental Resistance**: Many models are designed to withstand harsh environments, including dust, moisture, and extreme temperatures, ensuring reliable performance in challenging conditions.

7. **Easy Alignment and Installation**: With visible light sources like LEDs, alignment and installation are straightforward, reducing setup time and maintenance.

8. **Immunity to Electrical Noise**: They are less susceptible to electrical noise compared to inductive sensors, ensuring stable operation in electrically noisy environments.

9. **Compact Size**: Their small size allows for integration into tight spaces, making them ideal for applications with limited installation space.

10. **Cost-Effective**: While offering advanced features, they are often cost-effective, providing a good balance between performance and price.

These advantages make photoelectric proximity sensors a popular choice in automation, manufacturing, and various industrial applications.

How do you choose the right photoelectric sensor for an application?

To choose the right photoelectric sensor for an application, consider the following factors:

1. **Sensing Mode**: Determine the appropriate sensing mode based on the application requirements:

- **Through-beam**: Best for long-range detection and high reliability.

- **Retro-reflective**: Suitable for medium-range applications with a reflector.

- **Diffuse**: Ideal for short-range detection where the object reflects the light.

2. **Detection Range**: Assess the required sensing distance. Through-beam sensors offer the longest range, followed by retro-reflective and diffuse.

3. **Target Material and Surface**: Consider the material, color, and surface finish of the target. Diffuse sensors may struggle with shiny or transparent objects, while polarized retro-reflective sensors can handle such challenges better.

4. **Environmental Conditions**: Evaluate the operating environment, including temperature, humidity, dust, and potential exposure to chemicals or water. Choose sensors with appropriate IP ratings and materials.

5. **Response Time**: Ensure the sensor's response time matches the speed of the application to avoid missed detections.

6. **Size and Mounting**: Consider the physical size and mounting options to ensure compatibility with the installation space.

7. **Output Type**: Select the appropriate output type (PNP, NPN, analog) based on the control system requirements.

8. **Power Supply**: Ensure the sensor's voltage requirements align with the available power supply.

9. **Cost and Brand**: Balance the budget with the need for reliability and performance. Consider reputable brands known for quality and support.

10. **Additional Features**: Look for features like background suppression, adjustable sensitivity, or IO-Link connectivity if needed for the application.

By carefully evaluating these factors, you can select a photoelectric sensor that meets the specific needs of your application.

What are common applications for photoelectric proximity sensors?

Photoelectric proximity sensors are widely used in various industries due to their ability to detect objects without physical contact. Common applications include:

1. **Manufacturing and Automation**: These sensors are used for object detection on assembly lines, ensuring components are present and correctly positioned. They help in counting items, detecting jams, and verifying the presence of parts.

2. **Packaging Industry**: In packaging, photoelectric sensors detect the presence and position of packaging materials, ensuring proper alignment and sealing. They are also used to count products and verify labels.

3. **Material Handling**: They are employed in conveyor systems to detect the presence and position of items, preventing collisions and ensuring smooth flow of materials.

4. **Automotive Industry**: In automotive manufacturing, these sensors are used for position sensing, part detection, and quality control, ensuring components are correctly assembled.

5. **Food and Beverage Industry**: Photoelectric sensors are used to detect transparent bottles, check fill levels, and ensure packaging integrity, maintaining hygiene and quality standards.

6. **Security Systems**: They are used in security applications for intrusion detection, activating alarms when an object or person crosses a designated boundary.

7. **Robotics**: In robotics, these sensors help in object detection and navigation, allowing robots to interact with their environment safely and efficiently.

8. **Textile Industry**: They are used to monitor the presence and tension of threads and fabrics, ensuring consistent quality and preventing machine damage.

9. **Pharmaceutical Industry**: Photoelectric sensors ensure the correct packaging and labeling of medicines, maintaining compliance with regulatory standards.

10. **Elevators and Escalators**: They detect the presence of passengers, ensuring doors do not close prematurely and enhancing safety.

These applications highlight the versatility and importance of photoelectric proximity sensors in enhancing efficiency, safety, and quality across various sectors.