Push buttons are widely used as simple, user-friendly interfaces for controlling various devices and systems. They serve as a mechanism to initiate an action or process when pressed. Common applications include:

1. **Consumer Electronics**: In devices like televisions, remote controls, and gaming consoles, push buttons allow users to power on/off, change channels, adjust volume, and navigate menus.

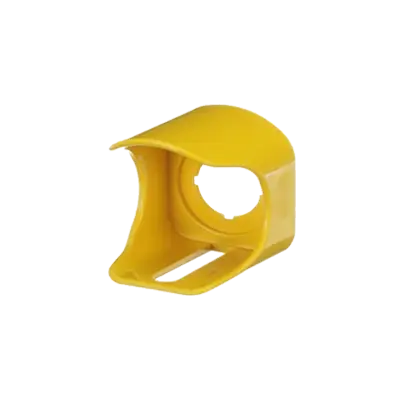

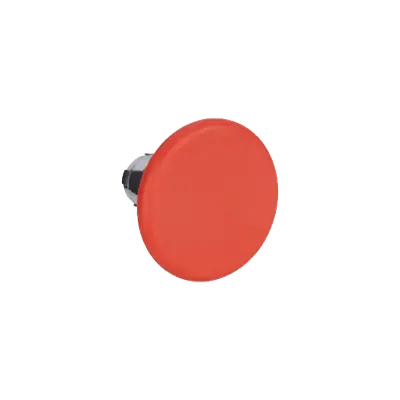

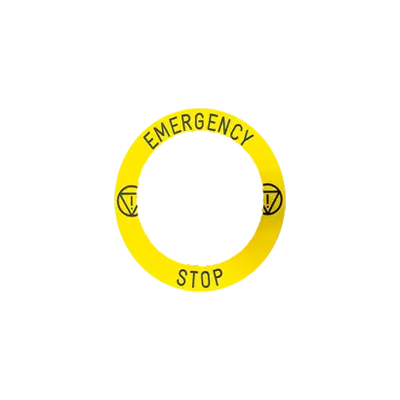

2. **Industrial Controls**: In manufacturing and industrial settings, push buttons are used to start and stop machinery, reset systems, and trigger emergency stop functions for safety.

3. **Computers and Peripherals**: Keyboards and mice use push buttons for typing and clicking, while power buttons on computers and monitors control device operation.

4. **Home Appliances**: Push buttons are found on microwaves, washing machines, and coffee makers, enabling users to select settings and start operations.

5. **Automotive**: In vehicles, push buttons are used for ignition, controlling windows, adjusting seats, and operating infotainment systems.

6. **Elevators and Public Transport**: Push buttons allow users to select floors in elevators and request stops on buses and trains.

7. **Security Systems**: Push buttons are integral to access control systems, allowing users to enter codes or activate alarms.

8. **Toys and Games**: Many toys and electronic games use push buttons to interact with the device, triggering sounds, lights, or movements.

9. **Medical Devices**: In medical equipment, push buttons are used to operate devices, adjust settings, and ensure precise control in critical applications.

Overall, push buttons are essential components in both simple and complex systems, providing a reliable and intuitive means for users to interact with technology.