.....Read More

Analog Panel Meters

Counter & Hour Meter Accessories

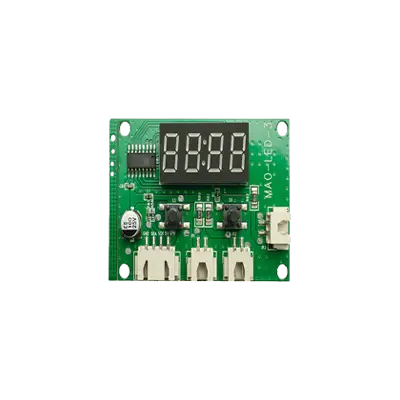

Counters, Hour Meters & Totalizers

Current Transducers

Digital Panel Meters

Energy Meters

Mechanical & Electronic Position Indicators

Mechanical & Hand Tally Counters

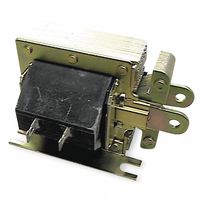

Mechanical Solenoids

Panel Meter Accessories

Panel Meter Shunts

PC and Work Station Enclosures

Pendant Arm System Components

Powder & Bulk Level Control Accessories

Powder & Bulk Level Controls

Pulse Generators

Rotary Encoder Accessories

Rotary Encoders

Signal Conditioners

Frequently Asked Questions

What is the purpose of using meters and counters in manufacturing?

How do counters help in tracking production output?

What are the benefits of using hour meters for heavy-duty equipment?

How can meters and counters improve facility efficiency?

What types of counters are commonly used in manufacturing?

How do hour meters estimate service times for equipment?

What factors should be considered when selecting meters and counters for a facility?