Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Fuses Circuit Breakers Safety Switches

- Fuses Accessories

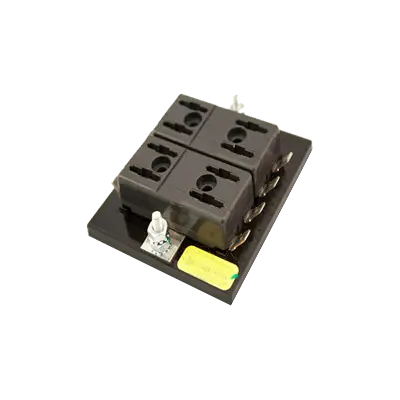

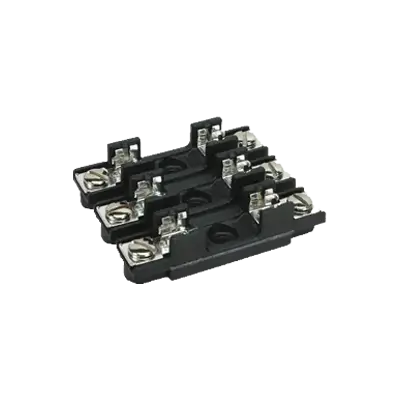

- Fuse Blocks Holders Covers

.....Read More

Frequently Asked Questions

What is the purpose of a fuse block and holder?

A fuse block and holder serve as a critical component in electrical systems, providing a safe and organized way to house and connect fuses. The primary purpose of a fuse block is to protect electrical circuits from overcurrent, which can cause damage to equipment, wiring, or even lead to fires. When the current flowing through a circuit exceeds the rated capacity of the fuse, the fuse element melts, interrupting the flow of electricity and thereby protecting the circuit.

The fuse holder is designed to securely hold the fuse in place, ensuring a stable connection within the circuit. It allows for easy installation and replacement of fuses without the need for specialized tools. Fuse holders can be designed for various types of fuses, including blade, cartridge, or glass tube fuses, and are available in different configurations to accommodate single or multiple fuses.

In addition to providing protection, fuse blocks and holders help organize electrical systems by grouping fuses in a centralized location. This organization simplifies maintenance and troubleshooting, as it allows for quick identification and replacement of blown fuses. Fuse blocks often include features such as labeling areas, which further aid in identifying circuits and their corresponding fuses.

Overall, the purpose of a fuse block and holder is to enhance the safety, reliability, and manageability of electrical systems by providing a secure, organized, and accessible means of incorporating fuses into circuits.

How do you choose the right fuse block for your application?

To choose the right fuse block for your application, consider the following factors:

1. **Voltage Rating**: Ensure the fuse block can handle the maximum voltage of your application. It should match or exceed the system's voltage requirements.

2. **Current Rating**: Select a fuse block that supports the maximum current your application will draw. It should be equal to or greater than the current rating of the fuse used.

3. **Fuse Type**: Determine the type of fuse (e.g., blade, cartridge, glass tube) your application requires and choose a compatible fuse block.

4. **Number of Circuits**: Identify how many circuits need protection and select a fuse block with the appropriate number of slots.

5. **Mounting Style**: Choose a mounting style (e.g., panel mount, surface mount, DIN rail) that fits your installation requirements.

6. **Environmental Conditions**: Consider the operating environment. For harsh conditions, select a fuse block with appropriate protection, such as waterproof or dustproof features.

7. **Material and Durability**: Ensure the fuse block is made from materials that can withstand the environmental and operational stresses, such as high temperatures or corrosive environments.

8. **Size and Space Constraints**: Ensure the fuse block fits within the available space in your application.

9. **Ease of Maintenance**: Consider how easy it is to replace fuses and maintain the fuse block.

10. **Compliance and Standards**: Ensure the fuse block complies with relevant industry standards and certifications for safety and performance.

11. **Cost**: Balance the cost with the features and reliability required for your application.

By evaluating these factors, you can select a fuse block that ensures safety, reliability, and efficiency for your specific application.

What are the different types of fuse holders available?

There are several types of fuse holders available, each designed to accommodate specific applications and fuse types:

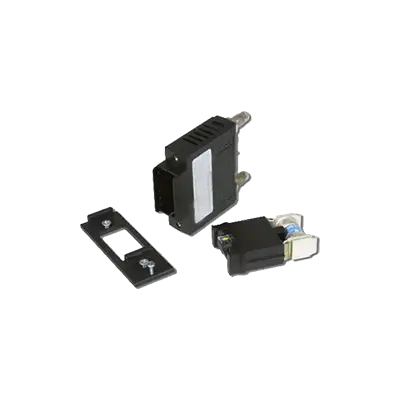

1. **Panel-Mount Fuse Holders**: These are designed to be mounted on panels or enclosures. They allow easy access for fuse replacement and are commonly used in consumer electronics and industrial equipment.

2. **In-Line Fuse Holders**: These are used in wiring systems where the fuse holder is integrated into the wire itself. They are ideal for automotive and marine applications, providing protection without the need for a panel.

3. **PCB Fuse Holders**: Designed for printed circuit boards, these holders allow fuses to be mounted directly onto the PCB. They are used in compact electronic devices and appliances.

4. **DIN Rail Fuse Holders**: These are mounted on DIN rails, commonly used in industrial control panels. They provide a secure and organized way to hold multiple fuses in a single location.

5. **Cartridge Fuse Holders**: Specifically designed for cartridge fuses, these holders can be panel-mounted or in-line. They are used in various applications, including industrial and commercial settings.

6. **Blade Fuse Holders**: Used for blade-type fuses, these holders are common in automotive applications. They can be panel-mounted or in-line and provide easy access for fuse replacement.

7. **Surface-Mount Fuse Holders**: These are used in surface-mount technology (SMT) applications, allowing fuses to be mounted directly onto the surface of a PCB.

8. **Fuse Blocks**: These are used to hold multiple fuses in a single block, providing a centralized location for fuse protection. They are often used in automotive and industrial applications.

9. **Fuse Clips**: Simple holders that clip onto the ends of a fuse, providing a basic and cost-effective solution for mounting fuses on PCBs or other surfaces.

Each type of fuse holder is designed to meet specific requirements, such as voltage, current rating, and environmental conditions, ensuring the safe and efficient operation of electrical systems.

How do you install a fuse block or holder?

1. **Safety First**: Disconnect the battery to prevent any electrical shock or short circuits.

2. **Select Location**: Choose a location that is easily accessible, away from heat sources, and where wires can be routed without strain.

3. **Mounting**: Secure the fuse block or holder using screws or adhesive, ensuring it is firmly attached to prevent movement.

4. **Wire Preparation**: Cut the wires to the appropriate length, strip the ends, and crimp on the necessary connectors (ring terminals, spade connectors, etc.).

5. **Connect Power Source**: Attach the main power wire from the battery or power distribution point to the input terminal of the fuse block. Ensure a secure connection.

6. **Connect Load Wires**: Connect the wires from the devices or circuits you are protecting to the output terminals of the fuse block.

7. **Insert Fuses**: Insert the appropriate fuses for each circuit, ensuring they match the required amperage for the devices they protect.

8. **Check Connections**: Double-check all connections for tightness and correctness to prevent any potential issues.

9. **Reconnect Battery**: Once everything is securely connected, reconnect the battery.

10. **Test**: Turn on the circuits to ensure everything is functioning correctly and that the fuses are not blowing immediately.

11. **Final Inspection**: Inspect the installation for any loose wires or potential hazards, and ensure the fuse block cover is securely in place.

What materials are fuse blocks and holders typically made from?

Fuse blocks and holders are typically made from materials that provide electrical insulation, mechanical strength, and thermal resistance. The main materials used include:

1. **Thermoplastics**: These are commonly used due to their excellent insulating properties, durability, and resistance to heat and chemicals. Examples include nylon, polycarbonate, and polyester. Thermoplastics are often chosen for their ability to withstand high temperatures without deforming.

2. **Thermosetting Plastics**: Materials like phenolic resins are used for their high heat resistance and structural integrity. They do not melt under heat, making them suitable for high-temperature applications.

3. **Ceramics**: Used in high-temperature and high-voltage applications, ceramics provide excellent thermal and electrical insulation. They are non-combustible and can withstand extreme conditions without degrading.

4. **Metals**: Conductive parts of fuse holders, such as clips and terminals, are typically made from metals like copper, brass, or tin-plated steel. These metals offer good electrical conductivity and corrosion resistance.

5. **Glass-Filled Plastics**: These are reinforced with glass fibers to enhance strength and thermal stability. They are used in applications where additional mechanical strength is required.

6. **Silicone Rubber**: Sometimes used for its flexibility and high-temperature resistance, especially in environments where vibration or movement is a concern.

These materials are selected based on the specific requirements of the application, such as the voltage and current ratings, environmental conditions, and mechanical stresses the fuse block or holder will encounter.

How do you maintain and troubleshoot fuse blocks and holders?

To maintain and troubleshoot fuse blocks and holders, follow these steps:

1. **Inspection**: Regularly inspect fuse blocks and holders for signs of wear, corrosion, or damage. Look for discoloration, cracks, or melted areas that indicate overheating.

2. **Cleaning**: Ensure the contacts are clean. Use a contact cleaner or a soft brush to remove dust and debris. Avoid abrasive materials that could damage the contacts.

3. **Tightening Connections**: Check that all connections are tight. Loose connections can cause arcing and overheating. Use a screwdriver to tighten any loose screws or terminals.

4. **Testing Fuses**: Use a multimeter to test fuses for continuity. Replace any blown fuses with ones of the correct rating to prevent circuit damage.

5. **Checking Ratings**: Verify that the fuse ratings match the circuit requirements. Using incorrect ratings can lead to inadequate protection or nuisance tripping.

6. **Replacement**: Replace any damaged or corroded fuse blocks and holders. Ensure replacements are compatible with the existing system.

7. **Thermal Inspection**: Use a thermal imaging camera to detect hot spots that may indicate poor connections or overloads.

8. **Documentation**: Keep records of maintenance and replacements to track the history and identify recurring issues.

9. **Safety Precautions**: Always de-energize circuits before performing maintenance. Use appropriate personal protective equipment (PPE) to prevent electrical shock.

10. **Troubleshooting**: If issues persist, trace the circuit to identify potential problems such as short circuits or overloads. Use schematic diagrams to assist in locating faults.

By following these steps, you can ensure the reliable operation of fuse blocks and holders, minimizing downtime and enhancing safety.

What safety precautions should be taken when working with fuse blocks and holders?

1. **De-energize Circuits**: Always ensure that the circuit is de-energized before working with fuse blocks and holders. Use a lockout/tagout (LOTO) procedure to prevent accidental re-energization.

2. **Use Personal Protective Equipment (PPE)**: Wear appropriate PPE such as insulated gloves, safety glasses, and flame-resistant clothing to protect against electrical shock and arc flash.

3. **Verify Absence of Voltage**: Use a properly rated voltage tester to confirm that the circuit is de-energized before starting work.

4. **Follow Manufacturer Guidelines**: Adhere to the manufacturer's instructions and specifications for installation, maintenance, and replacement of fuses and holders.

5. **Inspect Equipment**: Check fuse blocks and holders for signs of damage, corrosion, or wear. Replace any defective components before proceeding.

6. **Use Correct Tools**: Utilize insulated tools specifically designed for electrical work to prevent accidental contact with live parts.

7. **Select Proper Fuses**: Ensure that the replacement fuses match the required specifications for current rating, voltage rating, and type to prevent overloading and potential hazards.

8. **Maintain Clear Work Area**: Keep the work area clean and free of conductive materials to reduce the risk of accidental short circuits.

9. **Avoid Moisture**: Ensure that the work environment is dry to prevent electrical hazards associated with moisture.

10. **Secure Connections**: Make sure all connections are tight and secure to prevent arcing and overheating.

11. **Educate and Train**: Ensure that all personnel working with or around fuse blocks and holders are properly trained in electrical safety practices.

12. **Regular Maintenance**: Conduct regular inspections and maintenance of electrical systems to identify and rectify potential issues before they become hazardous.