Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

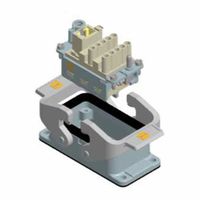

- Electrical

- Electrical Connectors Wiring Devices

- Rectangular Connectors

.....Read More

Frequently Asked Questions

What are the advantages of using modular rectangular connectors?

Modular rectangular connectors offer several advantages:

1. **Flexibility and Customization**: They allow for a high degree of customization, enabling users to configure connectors with different modules for power, signal, data, and pneumatic connections within a single housing. This flexibility supports diverse application needs.

2. **Space Efficiency**: Their compact design helps save space in equipment and systems, making them ideal for applications where space is limited.

3. **Ease of Installation and Maintenance**: Modular connectors are designed for easy assembly and disassembly, which simplifies installation and maintenance. This can lead to reduced downtime and lower labor costs.

4. **Scalability**: They can be easily expanded or reconfigured to accommodate changes in system requirements, providing scalability for future upgrades or modifications.

5. **Robustness and Durability**: Typically constructed from high-quality materials, these connectors offer excellent resistance to environmental factors such as dust, moisture, and vibration, ensuring reliable performance in harsh conditions.

6. **Improved Signal Integrity**: By allowing for the separation of different types of connections, modular rectangular connectors can reduce interference and improve signal integrity, which is crucial for high-performance applications.

7. **Cost-Effectiveness**: The ability to combine multiple functions into a single connector can reduce the number of connectors needed, lowering material costs and simplifying inventory management.

8. **Standardization**: Many modular rectangular connectors adhere to industry standards, ensuring compatibility and interoperability with a wide range of equipment and systems.

9. **Enhanced Safety**: They often include features such as locking mechanisms and coding options to prevent mismating and ensure secure connections, enhancing operational safety.

These advantages make modular rectangular connectors a preferred choice in industries such as automation, telecommunications, and transportation.

How do you select the right modular rectangular connector for your application?

To select the right modular rectangular connector for your application, consider the following factors:

1. **Application Requirements**: Determine the specific needs of your application, including the type of signals (power, data, or mixed), current and voltage ratings, and environmental conditions.

2. **Connector Type**: Choose between board-to-board, cable-to-board, or cable-to-cable connectors based on your system design.

3. **Number of Contacts**: Identify the number of contacts required to support your application’s signal and power needs. Ensure the connector can accommodate future expansion if necessary.

4. **Size and Space Constraints**: Evaluate the available space in your design. Select a connector that fits within these constraints while providing the necessary functionality.

5. **Material and Durability**: Consider the materials used in the connector, such as plastic or metal housings, and contact materials like gold or tin plating. Ensure they meet the durability and longevity requirements of your application.

6. **Environmental Conditions**: Assess the operating environment, including temperature, humidity, and exposure to chemicals or vibrations. Choose connectors with appropriate IP ratings and ruggedness.

7. **Mating Cycles**: Determine the number of mating cycles the connector will undergo. Select a connector with a suitable lifecycle rating to ensure reliability.

8. **Locking Mechanism**: Consider the need for a locking mechanism to prevent accidental disconnection, especially in high-vibration environments.

9. **Compliance and Standards**: Ensure the connector complies with relevant industry standards and certifications, such as RoHS, UL, or IEC.

10. **Cost and Availability**: Balance the cost with performance requirements. Check the availability of the connector to avoid supply chain issues.

11. **Manufacturer Support**: Choose a reputable manufacturer that offers technical support and documentation to assist with integration and troubleshooting.

By carefully evaluating these factors, you can select a modular rectangular connector that meets the specific needs of your application.

What are the common applications of industrial modular rectangular connectors?

Industrial modular rectangular connectors are widely used in various applications due to their versatility, reliability, and ease of customization. Common applications include:

1. **Automation and Robotics**: These connectors are crucial in connecting sensors, actuators, and control systems, facilitating efficient communication and power distribution in automated and robotic systems.

2. **Manufacturing Equipment**: They are used in machinery for transmitting signals and power, ensuring seamless operation of equipment like CNC machines, assembly lines, and packaging systems.

3. **Transportation**: In the automotive, railway, and aerospace industries, these connectors are employed for wiring harnesses, control systems, and power distribution, providing robust connections that withstand vibrations and environmental stresses.

4. **Energy and Power Distribution**: They are used in power plants, renewable energy systems, and electrical grids for connecting transformers, switchgear, and control panels, ensuring reliable power transmission and distribution.

5. **Telecommunications**: Modular rectangular connectors are used in network infrastructure for connecting data and communication lines, supporting high-speed data transfer and reliable connectivity.

6. **Medical Equipment**: In medical devices and diagnostic equipment, these connectors ensure secure and reliable connections for transmitting data and power, critical for patient monitoring and imaging systems.

7. **Military and Defense**: They are used in rugged environments for communication systems, radar, and other defense equipment, providing durable and secure connections that can withstand harsh conditions.

8. **Industrial Control Systems**: These connectors facilitate the integration of various control components, such as PLCs, HMIs, and sensors, ensuring efficient operation and monitoring of industrial processes.

9. **Consumer Electronics**: In some cases, they are used in high-end consumer electronics for connecting components that require robust and reliable connections.

Overall, industrial modular rectangular connectors are essential in any application requiring reliable, customizable, and durable connections for power, signal, and data transmission.

How do you install and maintain modular rectangular connectors?

To install and maintain modular rectangular connectors, follow these steps:

1. **Selection**: Choose the appropriate connector based on application requirements such as current rating, number of contacts, and environmental conditions.

2. **Preparation**: Gather necessary tools like crimping tools, screwdrivers, and wire strippers. Ensure all components are clean and free from damage.

3. **Cable Preparation**: Strip the cable to the required length, ensuring no damage to the conductors. For shielded cables, prepare the shield as per the connector's specifications.

4. **Contact Termination**: Use the correct crimping tool to attach contacts to the wires. Ensure a secure and reliable connection by following the manufacturer's crimping guidelines.

5. **Insert Contacts**: Place the terminated contacts into the connector housing. Ensure they are fully seated and locked in place.

6. **Assembly**: Assemble the connector housing according to the manufacturer's instructions. This may involve securing the housing with screws or latches.

7. **Mounting**: Install the connector onto the panel or equipment, ensuring it is securely fastened and aligned correctly.

8. **Testing**: Perform continuity and insulation resistance tests to ensure proper installation. Check for any misalignment or loose connections.

9. **Maintenance**: Regularly inspect connectors for signs of wear, corrosion, or damage. Clean contacts with appropriate cleaning agents and tools.

10. **Replacement**: Replace any damaged or worn components immediately to prevent failure.

11. **Documentation**: Keep records of installation and maintenance activities for future reference and compliance.

By following these steps, you can ensure reliable performance and longevity of modular rectangular connectors in your applications.

What materials are used in the construction of modular rectangular connectors?

Modular rectangular connectors are constructed using a variety of materials, each chosen for its specific properties to ensure performance, durability, and reliability. The primary materials used include:

1. **Plastics**: The housing or shell of modular rectangular connectors is typically made from high-performance plastics such as polycarbonate, polyamide (nylon), or polybutylene terephthalate (PBT). These materials offer excellent electrical insulation, mechanical strength, and resistance to environmental factors like moisture and temperature variations.

2. **Metals**: The contacts within the connectors are usually made from metals such as copper, brass, or phosphor bronze. These metals are chosen for their excellent electrical conductivity and mechanical properties. To enhance corrosion resistance and conductivity, these contacts are often plated with metals like gold, silver, or tin.

3. **Elastomers**: Seals and gaskets within the connectors are often made from elastomeric materials such as silicone or rubber. These materials provide effective sealing against dust, moisture, and other environmental contaminants, ensuring the connector's integrity and performance.

4. **Stainless Steel or Aluminum**: For connectors that require additional shielding or mechanical protection, materials like stainless steel or aluminum may be used for the outer shell or shielding components. These metals provide robust protection against electromagnetic interference (EMI) and physical damage.

5. **Thermoplastics with Flame Retardants**: In applications where fire safety is a concern, thermoplastics with flame-retardant additives are used to meet specific safety standards and regulations.

These materials are selected based on the specific requirements of the application, including electrical performance, environmental conditions, mechanical stress, and regulatory compliance. The combination of these materials ensures that modular rectangular connectors can perform reliably in a wide range of industrial, commercial, and consumer applications.

How do you ensure the reliability and durability of modular rectangular connectors in harsh environments?

To ensure the reliability and durability of modular rectangular connectors in harsh environments, consider the following strategies:

1. **Material Selection**: Use high-quality, corrosion-resistant materials such as stainless steel, nickel-plated brass, or thermoplastics for housings and contacts. These materials withstand extreme temperatures, moisture, and chemical exposure.

2. **Sealing and Enclosures**: Implement robust sealing solutions like O-rings, gaskets, and overmolding to prevent ingress of dust, water, and other contaminants. IP67 or IP68-rated enclosures provide enhanced protection.

3. **Contact Design**: Opt for gold-plated contacts to ensure low contact resistance and high conductivity. Use redundant contact points to maintain connectivity even if one point fails.

4. **Vibration and Shock Resistance**: Design connectors with secure locking mechanisms and strain relief features to withstand mechanical stresses. Use flexible, ruggedized cables to absorb vibrations.

5. **Thermal Management**: Incorporate materials and designs that dissipate heat effectively. Use connectors with high-temperature ratings to prevent degradation under thermal stress.

6. **Testing and Certification**: Conduct rigorous testing, including thermal cycling, salt spray, vibration, and shock tests, to simulate harsh conditions. Obtain relevant certifications like MIL-STD, IEC, or UL for assurance of performance standards.

7. **Modular Design**: Utilize modular designs that allow for easy replacement and maintenance of individual components without compromising the entire system.

8. **Redundancy and Fail-Safes**: Implement redundant systems and fail-safe mechanisms to ensure continued operation in case of partial failure.

9. **Regular Maintenance**: Establish a maintenance schedule for inspection, cleaning, and replacement of worn components to prolong service life.

10. **Environmental Adaptation**: Customize connectors for specific environmental conditions, such as UV resistance for outdoor applications or EMI shielding for electromagnetic interference-prone areas.

By integrating these strategies, modular rectangular connectors can achieve high reliability and durability in harsh environments.

What are the differences between modular rectangular connectors and other types of connectors?

Modular rectangular connectors and other types of connectors differ in several key aspects:

1. **Design and Structure**: Modular rectangular connectors are characterized by their rectangular shape and modular design, allowing for customization and flexibility in configuration. Other connectors, such as circular connectors, have a round shape and are often used for applications requiring robust environmental sealing.

2. **Application**: Modular rectangular connectors are commonly used in telecommunications and networking, such as RJ45 connectors for Ethernet cables. Other connectors, like circular connectors, are frequently used in military, aerospace, and industrial applications due to their durability and resistance to harsh conditions.

3. **Assembly and Installation**: Modular rectangular connectors often feature a snap-in or plug-and-play design, making them easy to assemble and install without specialized tools. Other connectors may require more complex assembly processes, including soldering or crimping.

4. **Customization and Scalability**: The modular nature of rectangular connectors allows for easy customization and scalability, enabling users to add or remove modules as needed. Other connectors may not offer the same level of flexibility, often being fixed in their configuration.

5. **Size and Space Efficiency**: Modular rectangular connectors are typically designed to be compact and space-efficient, making them suitable for high-density applications. Other connectors, particularly larger circular ones, may require more space.

6. **Performance and Reliability**: While modular rectangular connectors are reliable for data and signal transmission, other connectors, such as fiber optic connectors, may offer superior performance in terms of speed and bandwidth.

7. **Environmental Resistance**: Other connectors, especially those designed for harsh environments, often provide better resistance to moisture, dust, and temperature extremes compared to standard modular rectangular connectors.

These differences influence the choice of connector based on specific application requirements, environmental conditions, and performance needs.