Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Electrical Connectors Wiring Devices

- Plugs Receptacles Wiring Devices

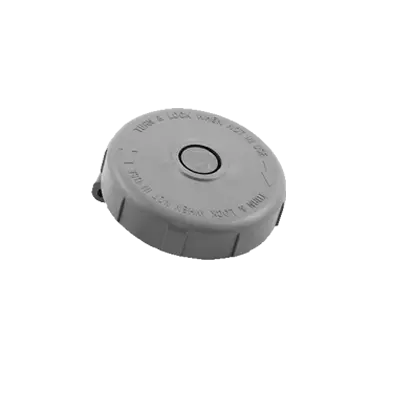

- Pin Sleeve Plugs Receptacles

.....Read More

Frequently Asked Questions

What are pin-and-sleeve plugs and receptacles?

Pin-and-sleeve plugs and receptacles are industrial-grade electrical connectors designed for safe and reliable power connections in harsh environments. They consist of a plug (male connector) and a receptacle (female connector) that together form a secure connection for electrical power distribution. These connectors are commonly used in industrial settings, such as manufacturing plants, construction sites, and outdoor installations, where durability and safety are paramount.

The design of pin-and-sleeve connectors includes cylindrical pins and sleeves that ensure a robust and secure connection. The pins are typically housed within the plug, while the sleeves are part of the receptacle. This configuration helps prevent accidental disconnection and ensures proper alignment during connection. The connectors are often color-coded and keyed to prevent mismatching of voltage and current ratings, enhancing safety.

Pin-and-sleeve connectors are available in various configurations to accommodate different voltage and current requirements, typically ranging from 20A to 100A and 120V to 600V. They are designed to meet international standards, such as IEC 60309, which ensures compatibility and safety across different regions and applications.

These connectors are constructed from durable materials, such as high-impact thermoplastics or metal, to withstand harsh conditions, including exposure to moisture, dust, chemicals, and temperature extremes. Many models are rated for ingress protection (IP), indicating their resistance to water and dust.

Overall, pin-and-sleeve plugs and receptacles provide a reliable, safe, and versatile solution for industrial power connections, ensuring consistent performance in demanding environments.

How do pin-and-sleeve connectors prevent mismatched connections?

Pin-and-sleeve connectors prevent mismatched connections through several design features:

1. **Keying System**: Each connector has a unique keying system that ensures only compatible plugs and receptacles can mate. The keying involves specific arrangements of pins and sleeves, which vary based on voltage, current, and phase configurations.

2. **Color Coding**: Connectors are often color-coded according to their voltage rating. This visual cue helps users quickly identify compatible components, reducing the risk of mismatching.

3. **Mechanical Design**: The physical design of the connectors includes different pin sizes and configurations. This means that a plug with a certain pin arrangement can only fit into a receptacle with a matching sleeve configuration.

4. **Voltage and Frequency Ratings**: Pin-and-sleeve connectors are designed with specific voltage and frequency ratings. The connectors for different ratings have distinct mechanical features that prevent interconnection with non-matching ratings.

5. **Ground Pin Positioning**: The ground pin is often larger and positioned differently from the other pins, ensuring that the plug can only be inserted in one orientation. This prevents incorrect connections that could lead to electrical faults.

6. **Locking Mechanism**: Many pin-and-sleeve connectors include a locking mechanism that secures the connection once mated. This prevents accidental disconnection and ensures a stable connection.

7. **Standards Compliance**: These connectors adhere to international standards (such as IEC 60309), which specify the dimensions, configurations, and safety features required to prevent mismatched connections.

By incorporating these features, pin-and-sleeve connectors ensure safe and reliable electrical connections, minimizing the risk of electrical hazards due to mismatched connections.

What safety features do pin-and-sleeve devices have to prevent electrical shocks?

Pin-and-sleeve devices incorporate several safety features to prevent electrical shocks:

1. **Grounding Pin**: The grounding pin is longer than the other pins, ensuring it connects first and disconnects last. This provides a path to ground before the circuit is energized, reducing shock risk.

2. **Polarized Design**: The design ensures that plugs can only be inserted in one orientation, maintaining correct polarity and preventing incorrect connections that could lead to shocks.

3. **IP Rating**: Pin-and-sleeve devices often have high Ingress Protection (IP) ratings, indicating resistance to dust and water. This prevents moisture and debris from entering the device, which could cause short circuits or shocks.

4. **Insulated Sleeves**: The pins are surrounded by insulated sleeves, which prevent accidental contact with live parts during connection and disconnection.

5. **Locking Mechanism**: Many devices feature a locking mechanism that secures the plug in place, preventing accidental disconnection and exposure to live contacts.

6. **Rugged Construction**: The robust construction of these devices, often using durable materials like rubber or plastic, provides additional insulation and protection against environmental factors.

7. **Color Coding**: Different voltage and frequency ratings are color-coded, reducing the risk of mismatched connections that could lead to electrical hazards.

8. **Temperature Resistance**: Materials used are often resistant to high temperatures, preventing deformation or damage that could expose live parts.

9. **Current Interruption**: Some designs include features that prevent the plug from being removed under load, reducing the risk of arcing and shock.

10. **Compliance with Standards**: These devices comply with international safety standards (e.g., IEC, UL), ensuring they meet rigorous safety requirements.

These features collectively enhance the safety of pin-and-sleeve devices, minimizing the risk of electrical shocks.

Where are pin-and-sleeve plugs and receptacles commonly used?

Pin-and-sleeve plugs and receptacles are commonly used in industrial and commercial environments where robust, reliable, and safe electrical connections are required. These environments include:

1. **Manufacturing Facilities**: They are used to power heavy machinery and equipment, providing secure connections that can withstand harsh conditions such as dust, moisture, and vibrations.

2. **Food and Beverage Industry**: Due to their watertight and corrosion-resistant properties, pin-and-sleeve devices are ideal for environments that require frequent washdowns and strict hygiene standards.

3. **Construction Sites**: These plugs and receptacles are used for temporary power distribution, offering durability and safety in rugged outdoor conditions.

4. **Entertainment and Events**: In theaters, concerts, and outdoor events, they provide reliable power connections for lighting, sound systems, and other equipment.

5. **Marine and Shipyards**: Their resistance to water and corrosion makes them suitable for use in marine environments, powering equipment on ships and in shipbuilding facilities.

6. **Mining Operations**: The robust design of pin-and-sleeve devices makes them suitable for the demanding conditions found in mining, where dust, moisture, and heavy machinery are prevalent.

7. **Data Centers**: They are used for high-power connections in data centers, ensuring reliable power supply to critical IT infrastructure.

8. **Agricultural Settings**: These devices are used to power equipment in farms and agricultural processing facilities, where exposure to dust and moisture is common.

9. **Chemical and Pharmaceutical Plants**: Their ability to withstand corrosive environments makes them suitable for use in chemical processing and pharmaceutical manufacturing.

10. **Transportation Hubs**: Airports, train stations, and bus depots use pin-and-sleeve devices for powering various equipment and systems.

Overall, pin-and-sleeve plugs and receptacles are chosen for their durability, safety features, and ability to maintain secure connections in challenging environments.

How do you install pin-and-sleeve receptacles and inlets?

1. **Select Location**: Choose a suitable location for installation, ensuring it is accessible and meets electrical code requirements.

2. **Turn Off Power**: Ensure the power supply to the installation area is turned off to prevent electrical shock.

3. **Prepare the Site**: Mark the mounting location and drill holes for the receptacle or inlet. Ensure the surface is clean and dry.

4. **Mount the Box**: Install a weatherproof or appropriate electrical box if required. Secure it firmly to the mounting surface.

5. **Wire Preparation**: Strip the insulation from the ends of the wires to the appropriate length as specified by the manufacturer.

6. **Connect Wires**:

- For receptacles, connect the wires to the corresponding terminals: ground (green), neutral (white), and hot (black or red).

- For inlets, ensure the wiring matches the intended power source configuration.

7. **Secure Connections**: Tighten all terminal screws securely to ensure a solid connection. Use a torque screwdriver if specified.

8. **Assemble Components**: Attach the receptacle or inlet to the box, ensuring the gasket (if provided) is in place for a weatherproof seal.

9. **Test Installation**: Once assembled, turn the power back on and test the receptacle or inlet with a multimeter to ensure proper voltage and grounding.

10. **Final Inspection**: Check for any loose connections or exposed wires. Ensure the installation complies with local electrical codes and standards.

11. **Labeling**: Clearly label the receptacle or inlet with the voltage and current rating for safety and future reference.

12. **Documentation**: Record the installation details, including date, location, and any specific configurations, for maintenance and troubleshooting purposes.

What are the benefits of using pin-and-sleeve connectors in industrial applications?

Pin-and-sleeve connectors offer several benefits in industrial applications:

1. **Durability**: Made from robust materials like polycarbonate or metal, these connectors withstand harsh environments, including exposure to chemicals, moisture, and extreme temperatures.

2. **Safety**: They feature a design that prevents accidental disconnection and ensures a secure connection. The connectors are often color-coded and keyed to prevent mismatching, reducing the risk of electrical hazards.

3. **Water and Dust Resistance**: With high IP ratings, pin-and-sleeve connectors are resistant to water and dust ingress, making them suitable for outdoor and washdown environments.

4. **High Current Capacity**: They can handle high current loads, making them ideal for heavy-duty industrial equipment and machinery.

5. **Ease of Use**: The connectors are designed for quick and easy installation and disconnection, minimizing downtime during maintenance or equipment changeovers.

6. **Versatility**: Available in various configurations and sizes, they can be used for different voltage and current requirements, accommodating a wide range of industrial applications.

7. **Compliance and Standards**: They meet international standards such as IEC 60309, ensuring compatibility and safety across global operations.

8. **Reduced Maintenance**: The robust design and materials reduce wear and tear, leading to lower maintenance costs and longer service life.

9. **Enhanced Performance**: Reliable connections ensure consistent power delivery, improving the performance and efficiency of industrial equipment.

10. **Cost-Effectiveness**: While the initial investment may be higher, the long-term benefits of reduced downtime, maintenance, and enhanced safety contribute to overall cost savings.

How do you maintain and troubleshoot pin-and-sleeve plugs and receptacles?

To maintain and troubleshoot pin-and-sleeve plugs and receptacles, follow these steps:

1. **Regular Inspection**: Periodically inspect plugs and receptacles for signs of wear, corrosion, or damage. Check for cracks, discoloration, or any physical deformities.

2. **Cleaning**: Clean contacts and surfaces with a non-abrasive cloth and a suitable electrical contact cleaner to remove dirt, dust, and oxidation. Ensure the cleaning agent is compatible with the materials.

3. **Tightening Connections**: Ensure all screws and connections are tight. Loose connections can lead to overheating and failure.

4. **Check for Corrosion**: Look for signs of corrosion, especially in outdoor or wet environments. Use anti-corrosion sprays or grease to protect metal parts.

5. **Test Functionality**: Use a multimeter to test continuity and ensure proper electrical flow. Check for correct voltage and current ratings.

6. **Inspect Gaskets and Seals**: Ensure that gaskets and seals are intact to maintain the IP rating and prevent moisture ingress.

7. **Replacement of Damaged Parts**: Replace any damaged or worn-out parts immediately to prevent electrical hazards.

8. **Verify Compatibility**: Ensure that plugs and receptacles are compatible in terms of voltage, current, and environmental ratings.

9. **Training and Safety**: Ensure personnel are trained in handling and maintaining these components safely. Use appropriate personal protective equipment (PPE).

10. **Documentation**: Keep records of maintenance activities, inspections, and any replacements or repairs conducted.

11. **Troubleshooting**: If issues arise, isolate the problem by checking individual components. Use diagnostic tools to identify faults in wiring or connections.

12. **Consult Manufacturer Guidelines**: Always refer to the manufacturer's guidelines for specific maintenance and troubleshooting procedures.

By following these steps, you can ensure the reliability and safety of pin-and-sleeve plugs and receptacles.