- Home

- Electrical

- Electrical Connectors Wiring Devices

- Plugs Receptacles Wiring Devices

- Nema Straight Blade Plugs Receptacles

.....Read More

Combination NEMA Straight-Blade Receptacles With Switches

Commercial Straight-Blade Connectors

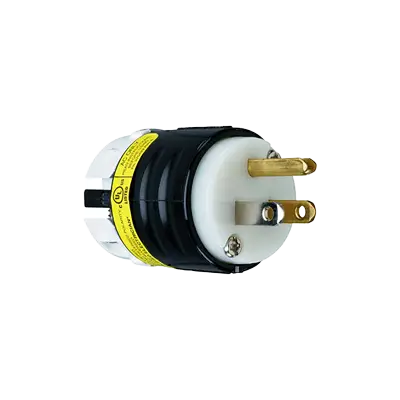

Commercial Straight-Blade Plugs

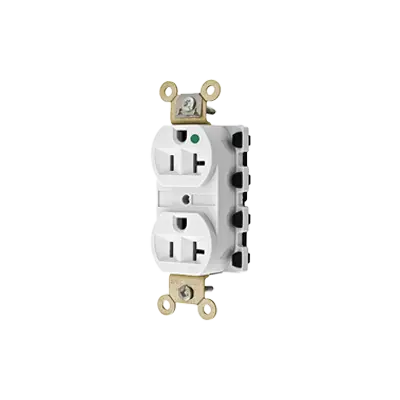

Commercial Straight-Blade Receptacles

Commercial Straight-Blade Receptacles with USB Ports

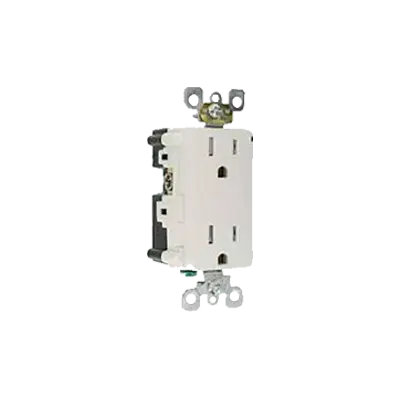

GFCI Blank Face Receptacles

Hazardous-Location Straight-Blade Plugs

Hazardous-Location Straight-Blade Receptacles

Hospital-Grade Straight-Blade Connectors

Hospital-Grade Straight-Blade Plugs

Hospital-Grade Straight-Blade Receptacles

Hospital-Grade Straight-Blade Receptacles with USB Ports

Industrial Straight-Blade Connectors

Industrial Straight-Blade Plugs

Industrial Straight-Blade Receptacles

NEMA Straight-Blade Accessories

NEMA Straight-Blade Inlets

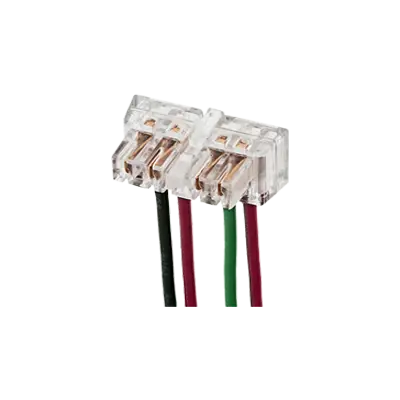

Snap-In Receptacle Wiring Modules

Watertight Straight-Blade Connectors

Watertight Straight-Blade Plugs

Watertight Straight-Blade Receptacles

Frequently Asked Questions

What are NEMA straight-blade plugs and receptacles?

How do NEMA plugs and receptacles ensure safety?

What are the different current ratings for NEMA devices?

How do NEMA pin/socket configurations prevent mismatched connections?

What is the difference between a NEMA plug and a connector?

How do you identify the correct NEMA receptacle for a specific plug?

What are the installation requirements for NEMA inlets and receptacles?