- Home

- Electrical

- Conduit Fittings Strut Channel Framing

- Conduit Fittings

- Metal Conduit Fittings

.....Read More

Access Fittings for Metal Conduit

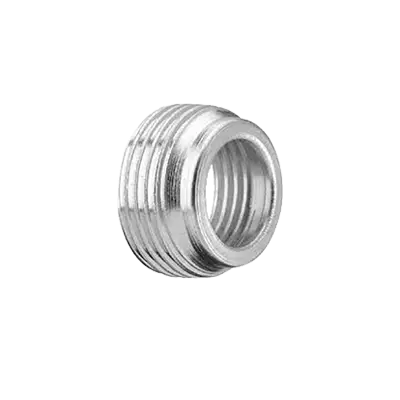

Bushings & Reducer Bushings for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Connectors for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Connectors for Thin-Wall EMT Metal Conduit

Couplings for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Couplings for Thin-Wall EMT Metal Conduit

Elbows for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Elbows for Thin-Wall EMT Metal Conduit

End Caps & Plugs for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Expansion Fittings

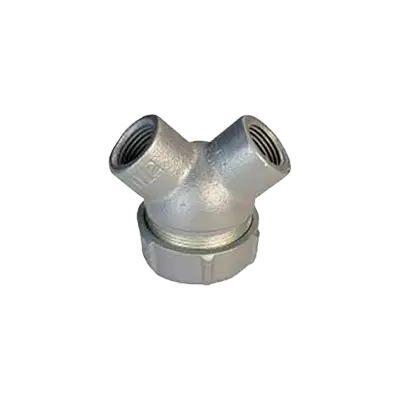

Hazardous Location Access Fittings

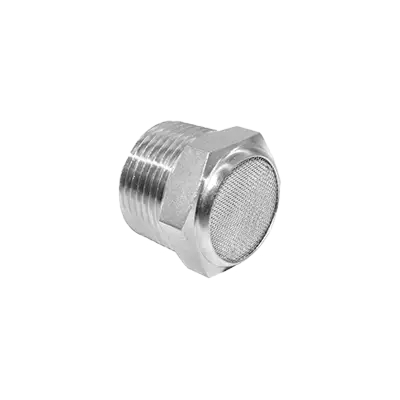

Hazardous Location Blank Plugs

Hazardous Location Capped Elbows

Hazardous Location Conduit Elbows

Hazardous Location Conduit Flexible Couplings

Hazardous Location Conduit Unions, Expansion Unions & Nipples

Hazardous Location Drains & Breathers

Hazardous Location Reducing Bushings

Hazardous Location Sealing Fittings

Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Hubs for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

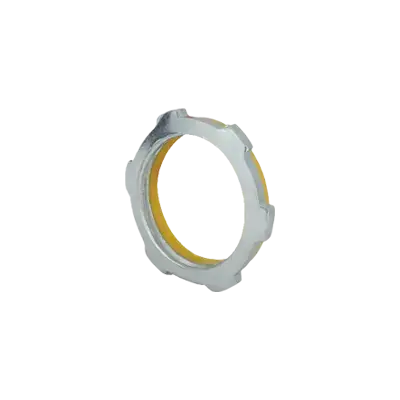

Locknuts for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Nipples for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Service Entrance Caps for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Thin-Wall EMT Metal Conduit

Wall Grommets for Heavy-Wall RMC & Medium-Wall IMC Metal Conduit

Frequently Asked Questions

What is the difference between RMC, IMC, and EMT conduit?

How do you bend EMT conduit?

What are the specific fittings used for each type of metal conduit?

How do you join metal conduit to enclosures and devices?

What are access fittings and when are they used?

How do you cut metal conduit?

What are the applications for heavy-wall RMC and medium-wall IMC conduit?