Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Adhesives Sealants And Tape

- Tape

- Mounting Bonding Tape Dispensers

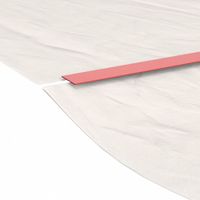

- Splicing Tape

.....Read More

Frequently Asked Questions

What is splicing tape used for?

Splicing tape is a specialized adhesive tape used primarily for joining two ends of materials together to create a continuous flow. It is commonly used in various industries, including film, audio, printing, and manufacturing.

In the film and audio industries, splicing tape is used to join segments of film or magnetic tape. This is crucial for editing purposes, allowing for seamless transitions between scenes or audio tracks. The tape is designed to be strong yet thin, ensuring that it does not interfere with playback or projection.

In the printing industry, splicing tape is used to join rolls of paper or other substrates. This is essential for maintaining continuous production runs, minimizing downtime, and reducing waste. The tape must be able to withstand the high speeds and tensions of modern printing presses.

In manufacturing, splicing tape is used to join materials such as textiles, plastics, or metals. This is important for processes that require continuous material feed, such as in the production of fabrics, films, or foils. The tape must be durable and resistant to environmental factors like heat, moisture, or chemicals.

Splicing tape is available in various types, including single-sided and double-sided, and is made from materials like polyester, paper, or polypropylene. The adhesive used is typically pressure-sensitive, allowing for easy application and strong bonding.

Overall, splicing tape is a critical tool for ensuring efficiency and continuity in various production and editing processes, providing a reliable means of joining materials without compromising quality or performance.

How do you apply splicing tape?

To apply splicing tape, follow these steps:

1. **Preparation**: Ensure the surfaces to be spliced are clean and dry. Remove any dust, dirt, or oils that might prevent the tape from adhering properly.

2. **Align Materials**: Position the two materials or ends to be spliced so they are aligned correctly. This is crucial for a seamless splice.

3. **Cut Tape**: Cut a piece of splicing tape slightly longer than the width of the materials being joined. This ensures full coverage and a secure bond.

4. **Apply Tape**: Peel off a small section of the tape backing to expose the adhesive. Carefully place the exposed adhesive side onto the aligned materials, starting at one end.

5. **Smooth and Secure**: As you apply the tape, use a roller or your fingers to press down firmly, smoothing out any air bubbles and ensuring full contact with the surfaces.

6. **Overlap Edges**: If necessary, overlap the tape slightly beyond the edges of the materials to ensure a strong bond and prevent peeling.

7. **Trim Excess**: Use a sharp blade or scissors to trim any excess tape for a neat finish.

8. **Press Firmly**: Go over the entire length of the tape with a roller or your fingers to ensure maximum adhesion and eliminate any remaining air pockets.

9. **Cure Time**: Allow the tape to set or cure as per the manufacturer's instructions, if applicable, to achieve optimal bonding strength.

10. **Test the Splice**: Gently test the splice by applying light tension to ensure the materials are securely joined.

By following these steps, you can effectively apply splicing tape for a durable and reliable bond.

What are the types of splicing tape?

Splicing tapes are specialized adhesive tapes used to join two ends of materials, such as paper, film, or fabric, during manufacturing processes. The main types of splicing tapes include:

1. **Single-Coated Splicing Tape**: This type has adhesive on one side and is used for temporary splicing applications. It is ideal for situations where the tape needs to be removed after the process.

2. **Double-Coated Splicing Tape**: Featuring adhesive on both sides, this tape is used for permanent splicing. It provides strong adhesion and is suitable for high-speed applications.

3. **Repulpable Splicing Tape**: Designed for the paper industry, this tape is water-soluble and can be broken down during the paper recycling process, ensuring no contamination.

4. **Non-Repulpable Splicing Tape**: Used in applications where repulpability is not required, offering strong adhesion and durability for non-recyclable materials.

5. **Heat-Activated Splicing Tape**: This tape requires heat to activate the adhesive, providing a strong bond. It is used in applications where high temperatures are involved.

6. **Silicone Splicing Tape**: Ideal for splicing silicone-coated materials, this tape has a silicone adhesive that bonds well with similar surfaces.

7. **High-Temperature Splicing Tape**: Designed to withstand extreme temperatures, this tape is used in processes involving heat, such as in the production of certain films and foils.

8. **Low-Temperature Splicing Tape**: Suitable for cold environments, this tape maintains its adhesive properties at low temperatures.

9. **Static Dissipative Splicing Tape**: Used in electronic applications, this tape prevents static build-up, protecting sensitive components.

10. **Colored Splicing Tape**: Available in various colors for easy identification and differentiation of splices during production.

Each type of splicing tape is engineered for specific applications, ensuring optimal performance and efficiency in various industrial processes.

What materials can splicing tape join?

Splicing tape is a versatile adhesive product used to join various materials, primarily in industrial and manufacturing settings. It is designed to provide a strong, durable bond and is often used in processes where materials need to be joined seamlessly. Here are the materials that splicing tape can effectively join:

1. **Paper**: Splicing tape is commonly used in the paper industry to join paper rolls during production processes, ensuring continuous operation without stopping the machinery.

2. **Film**: It is used to splice plastic films, such as polyethylene, polypropylene, and polyester, which are prevalent in packaging and labeling industries.

3. **Foil**: Splicing tape can join metal foils, including aluminum foil, which is used in various applications like packaging, insulation, and electronics.

4. **Textiles**: In textile manufacturing, splicing tape can join fabric rolls, aiding in seamless production and reducing downtime.

5. **Non-wovens**: These materials, used in hygiene products and medical supplies, can be spliced using specialized tapes designed for non-woven fabrics.

6. **Rubber**: Certain splicing tapes are formulated to bond rubber materials, which are used in automotive and industrial applications.

7. **Composite Materials**: In industries like aerospace and automotive, splicing tape can join composite materials, which are crucial for lightweight and high-strength applications.

8. **Labels and Tags**: Splicing tape is used to join rolls of labels and tags, ensuring efficient production and application processes.

Splicing tapes are available in various formulations, including single-sided, double-sided, heat-activated, and pressure-sensitive adhesives, to suit different materials and application requirements. The choice of splicing tape depends on factors such as the material type, environmental conditions, and the specific demands of the production process.

Is splicing tape heat resistant?

Splicing tape is generally designed to join or repair materials, often in industrial or manufacturing settings. Its heat resistance varies depending on the type and intended application. Some splicing tapes are specifically engineered to withstand high temperatures, while others are not.

High-temperature splicing tapes are typically made from materials like polyester, polyimide, or glass cloth, which can endure elevated temperatures. These tapes often have silicone or acrylic adhesives that maintain their bond under heat. Such tapes are used in applications like electronics, automotive, or any environment where exposure to high temperatures is expected.

On the other hand, standard splicing tapes, which might be made from materials like paper or basic plastic films, may not offer significant heat resistance. These are suitable for general-purpose applications where heat exposure is minimal or non-existent.

When selecting a splicing tape for heat resistance, it is crucial to consider the specific temperature range it can withstand, as well as the duration of exposure. Manufacturers typically provide specifications regarding the maximum temperature the tape can handle. For instance, polyimide tapes can often resist temperatures up to 500°F (260°C), making them suitable for extreme conditions.

In summary, while some splicing tapes are heat resistant, not all are. It is essential to choose the right type based on the specific requirements of the application, particularly the temperature conditions it will face.

Can splicing tape be used for electrical applications?

Splicing tape is primarily designed for joining or repairing film, paper, or other materials in non-electrical applications. It is typically used in industries like printing, packaging, and media production. The adhesive and backing materials of splicing tape are optimized for these purposes, focusing on strong adhesion, flexibility, and sometimes heat resistance, but not necessarily electrical insulation or conductivity.

For electrical applications, specialized electrical tapes are recommended. These tapes are specifically engineered to handle electrical insulation, resist voltage, and provide protection against environmental factors like moisture, UV light, and temperature variations. Electrical tapes are usually made from materials like PVC or rubber, which offer the necessary dielectric strength and thermal stability required for electrical work.

Using splicing tape in electrical applications could pose risks such as inadequate insulation, leading to potential short circuits, electrical failures, or even fire hazards. The adhesive on splicing tape may not withstand the thermal and electrical stresses encountered in electrical environments, potentially leading to tape failure.

In summary, while splicing tape is excellent for its intended purposes, it is not suitable for electrical applications. For safety and reliability, always use tapes specifically designed for electrical work.

How strong is splicing tape?

Splicing tape is designed to provide a strong, reliable bond for joining materials, particularly in industrial and manufacturing settings. Its strength is determined by several factors, including the type of adhesive used, the backing material, and the specific application for which it is designed.

1. **Adhesive Strength**: Splicing tapes typically use high-performance adhesives, such as acrylic, rubber, or silicone, which offer excellent adhesion to a variety of surfaces. Acrylic adhesives are known for their durability and resistance to environmental factors, while rubber adhesives provide strong initial tack and are suitable for quick bonding.

2. **Backing Material**: The backing material of splicing tape can vary, including options like polyester, paper, or film. Polyester-backed tapes are particularly strong and resistant to tearing, making them suitable for high-stress applications. Paper-backed tapes are often used for temporary splicing due to their ease of removal.

3. **Temperature and Environmental Resistance**: Many splicing tapes are engineered to withstand extreme temperatures, humidity, and chemical exposure, maintaining their strength in challenging conditions. This makes them ideal for use in industries like paper manufacturing, film production, and electronics.

4. **Tensile Strength**: The tensile strength of splicing tape is a critical measure of its ability to withstand pulling forces. High tensile strength ensures that the tape can hold materials together under tension without breaking.

5. **Application-Specific Strength**: The strength of splicing tape can also be tailored to specific applications, such as high-speed splicing in paper mills or delicate splicing in film production, ensuring optimal performance for the intended use.

Overall, splicing tape is engineered to provide robust, reliable bonding, with strength characteristics tailored to meet the demands of specific industrial applications.