Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

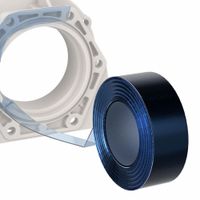

- Adhesives Sealants And Tape

- Tape

- Masking Tape Painter S Tape Dispensers

- High Temperature Film Masking Tape Tape Shapes

.....Read More

Frequently Asked Questions

What is the maximum temperature resistance of this film masking tape?

The maximum temperature resistance of film masking tape typically ranges from 120°C to 260°C (248°F to 500°F), depending on the specific type and material of the tape.

How does this tape conform to uneven surfaces?

The tape conforms to uneven surfaces through a combination of its material properties and adhesive technology. Typically, such tape is made from a flexible backing material, like vinyl, cloth, or a polymer blend, which allows it to stretch and bend. This flexibility enables the tape to adapt to the contours of irregular surfaces without tearing or losing its structural integrity.

The adhesive used is often pressure-sensitive, meaning it activates and adheres more effectively when pressure is applied. This type of adhesive can flow into the microscopic crevices and textures of an uneven surface, creating a strong bond. The adhesive's viscoelastic properties allow it to maintain contact with the surface even as it shifts or moves, ensuring continued adhesion.

Additionally, the tape's thickness can play a role in its ability to conform. A thicker tape can bridge small gaps and provide a cushioning effect, which helps it adhere to rough or bumpy surfaces. Some tapes also have a reinforced structure, such as a mesh or fabric layer, which provides additional strength and flexibility.

In some cases, the tape may be designed with a specific pattern or texture on its adhesive side to enhance its grip on uneven surfaces. This design can increase the surface area in contact with the substrate, improving adhesion.

Overall, the combination of a flexible backing, pressure-sensitive adhesive, and possibly a reinforced structure or textured design allows the tape to effectively conform to and adhere to uneven surfaces.

Is the tape available in different colors for visibility?

Yes, tape is available in different colors for visibility. Various types of tape, such as duct tape, electrical tape, and marking tape, come in a wide range of colors to serve different purposes. These colors can enhance visibility, improve safety, and aid in organization. For instance, brightly colored tapes like neon or fluorescent options are often used in construction or industrial settings to mark hazards or pathways, ensuring they are easily noticeable. In electrical work, different colors of electrical tape can indicate different phases or functions, helping to prevent errors. Additionally, colored tapes are used in arts and crafts, packaging, and home organization to differentiate items or add aesthetic appeal. The availability of multiple colors allows users to select the most appropriate option for their specific needs, ensuring both functionality and safety.

Can this tape be used for powder coating applications?

No, standard tapes are generally not suitable for powder coating applications. Powder coating involves applying a dry powder to a surface and then curing it under heat to form a solid layer. This process requires materials that can withstand high temperatures, typically between 350°F to 400°F (177°C to 204°C), without degrading or losing adhesion.

For powder coating, specialized high-temperature masking tapes are used. These tapes are usually made from materials like polyester or polyimide, which can endure the curing temperatures without melting, burning, or leaving residue. They also have a silicone adhesive that maintains its properties under high heat.

Standard tapes, such as those made from paper or low-temperature plastics, will not perform well in these conditions. They may melt, burn, or leave adhesive residue on the surface, which can interfere with the powder coating process and result in a poor finish.

Therefore, if you are considering using tape for powder coating, ensure it is specifically designed for high-temperature applications.

Does the tape leave any residue upon removal?

The residue left by tape upon removal depends on several factors, including the type of tape, the surface it was applied to, and the duration it was left in place.

1. **Type of Tape**:

- **Masking Tape**: Generally low-residue, but can leave residue if left on surfaces for extended periods.

- **Duct Tape**: Known for leaving a sticky residue due to its strong adhesive.

- **Painter's Tape**: Designed to be low-residue, making it ideal for temporary applications.

- **Double-Sided Tape**: Often leaves residue, especially if used on porous surfaces.

- **Packing Tape**: Can leave residue, particularly on paper or cardboard.

2. **Surface Type**:

- **Smooth Surfaces**: Less likely to retain residue, but some adhesives can still leave a film.

- **Porous Surfaces**: More prone to residue as the adhesive can seep into the material.

- **Delicate Surfaces**: May suffer damage or residue if the adhesive is too strong.

3. **Duration**:

- **Short-Term Use**: Less likely to leave residue, especially with tapes designed for temporary use.

- **Long-Term Use**: Increases the likelihood of residue as the adhesive bonds more strongly over time.

4. **Environmental Factors**:

- **Temperature and Humidity**: High temperatures can soften adhesives, increasing residue risk. Humidity can also affect adhesive properties.

5. **Removal Technique**:

- **Slow and Steady**: Gently peeling the tape back at a 45-degree angle can minimize residue.

- **Heat Application**: Using a hairdryer to warm the adhesive can help reduce residue.

In summary, while some tapes are designed to minimize residue, factors like tape type, surface, duration, and environmental conditions play significant roles in whether residue is left behind.

What are the available sizes for continuous rolls and precut shapes?

Continuous rolls and precut shapes are available in various sizes to cater to different needs across industries such as packaging, crafting, and manufacturing.

**Continuous Rolls:**

1. **Width:** Typically range from 1 inch to 60 inches. Common widths include 12, 18, 24, 36, and 48 inches.

2. **Length:** Varies significantly, often from 10 feet to 1000 feet or more. Standard lengths include 50, 100, 200, 500, and 1000 feet.

3. **Thickness:** Can range from 0.5 mil to 10 mil or more, depending on the material and application.

**Precut Shapes:**

1. **Circles:** Diameters can range from 1 inch to 12 inches or more. Common sizes include 2, 4, 6, and 8 inches.

2. **Squares/Rectangles:** Sizes vary widely, from small 1x1 inch squares to larger 12x12 inch or 24x36 inch rectangles.

3. **Labels/Stickers:** Often available in standard sizes like 2x4 inches, 3x5 inches, or 4x6 inches.

4. **Custom Shapes:** Many suppliers offer custom precut shapes tailored to specific requirements, with dimensions varying based on client needs.

These sizes are subject to availability and may vary by manufacturer or supplier. Customization options are often available for both continuous rolls and precut shapes to meet specific project requirements.

How does this tape perform in solder masking applications?

The tape performs effectively in solder masking applications due to its heat resistance, adhesive strength, and conformability. It is typically made from materials like polyimide or polyester, which can withstand the high temperatures involved in soldering processes, often up to 260°C (500°F) or more. This heat resistance ensures that the tape does not degrade or lose adhesion during soldering.

The adhesive used in these tapes is designed to provide strong adhesion to various substrates, including printed circuit boards (PCBs), while also allowing for clean removal without leaving residue. This is crucial in maintaining the integrity of the board and ensuring that no contaminants interfere with the soldering process or the functionality of the board.

Additionally, the tape's conformability allows it to adhere to uneven surfaces and complex geometries, providing effective masking of areas that should not be exposed to solder. This ensures precision in the soldering process, preventing solder bridges and ensuring that only the desired areas are soldered.

The tape also offers chemical resistance, protecting the masked areas from flux and other chemicals used during soldering. This further ensures that the board's performance is not compromised by chemical exposure.

Overall, the tape's combination of heat resistance, strong yet clean-removing adhesive, conformability, and chemical resistance makes it an ideal choice for solder masking applications, ensuring precision and reliability in electronic manufacturing processes.