Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

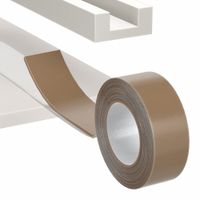

- Adhesives Sealants And Tape

- Tape

- Adhesive Transfer Tape Dispensers

.....Read More

Frequently Asked Questions

What is adhesive transfer tape used for?

Adhesive transfer tape is used for bonding, mounting, and laminating applications across various industries. It consists of a thin layer of adhesive pre-applied to a release liner, which is transferred to a substrate when pressure is applied. This type of tape is particularly useful for applications requiring a clean, precise bond without the bulk of a traditional tape backing.

In manufacturing and assembly, adhesive transfer tape is employed to bond materials such as metals, plastics, and composites. It is ideal for creating strong, durable bonds in electronics, automotive, and aerospace industries, where precision and reliability are crucial. The tape's thin profile allows for seamless integration into designs without adding significant weight or thickness.

In the graphics and signage industry, adhesive transfer tape is used for mounting signs, displays, and graphics. It provides a clean, professional finish, ensuring that the visual elements remain the focal point without visible fasteners or adhesives. The tape's ability to adhere to a variety of surfaces, including textured and irregular ones, makes it versatile for creative applications.

In packaging, adhesive transfer tape is used for sealing, splicing, and reinforcing packages. It offers a secure bond that withstands handling and transportation stresses, ensuring the integrity of the package contents. Additionally, it is used in the production of labels and stickers, providing a strong adhesive layer that ensures they remain affixed to surfaces.

Overall, adhesive transfer tape is valued for its ease of use, clean application, and ability to create strong, reliable bonds in a wide range of applications. Its versatility and efficiency make it a preferred choice for industries requiring precise and durable adhesive solutions.

How do you load an ATG dispenser?

1. **Preparation**: Ensure you have the correct ATG (Automatic Tank Gauging) dispenser model manual. Wear appropriate safety gear, including gloves and goggles.

2. **Safety Check**: Verify that the dispenser is turned off and isolated from any power source. Ensure the area is well-ventilated and free from ignition sources.

3. **Inspect Equipment**: Check the dispenser and surrounding area for any signs of damage or leaks. Ensure all components are clean and in good condition.

4. **Gather Materials**: Obtain the necessary materials for loading, such as the product to be dispensed, any required tools, and the ATG system components.

5. **Open Dispenser**: Unlock and open the dispenser cabinet using the appropriate key or tool. Ensure you have clear access to the loading area.

6. **Connect Hoses**: Attach the appropriate hoses to the dispenser. Ensure all connections are secure and leak-free. Use the correct fittings as specified in the manual.

7. **Load Product**: Carefully load the product into the dispenser. Follow the manufacturer's guidelines for the specific product type and quantity.

8. **Check Levels**: Use the ATG system to verify the product levels. Ensure the system is calibrated and functioning correctly to provide accurate readings.

9. **Secure Dispenser**: Once loading is complete, securely close and lock the dispenser cabinet. Ensure all tools and materials are removed from the area.

10. **Power On**: Reconnect the power supply and turn on the dispenser. Monitor the system for any irregularities or error messages.

11. **Test Dispensing**: Conduct a test dispense to ensure the system is operating correctly. Check for proper flow rate and accuracy.

12. **Documentation**: Record the loading process, including product type, quantity, and any observations, in the maintenance log for future reference.

What are the benefits of using adhesive transfer tape?

Adhesive transfer tape offers several benefits, making it a versatile choice for various applications:

1. **Precision and Clean Application**: Adhesive transfer tape provides a clean and precise application, as it allows for the adhesive to be applied directly to the surface without any mess. This is particularly beneficial in applications requiring exact placement, such as in graphic arts or electronics.

2. **Strong Bonding**: It offers strong bonding capabilities, suitable for both lightweight and heavy-duty applications. The adhesive is designed to adhere to a wide range of surfaces, including metals, plastics, and paper, ensuring durability and reliability.

3. **Thin and Lightweight**: The tape is thin and lightweight, which is ideal for applications where minimal bulk is required. This makes it suitable for use in electronics, where space is often limited, or in packaging, where weight is a concern.

4. **Versatility**: Adhesive transfer tape is versatile and can be used in various industries, including automotive, aerospace, construction, and arts and crafts. It is available in different adhesive strengths and thicknesses to suit specific needs.

5. **Ease of Use**: The tape is easy to handle and apply, often coming with a liner that can be easily removed to expose the adhesive. This simplifies the application process, reducing time and labor costs.

6. **Temperature and Environmental Resistance**: Many adhesive transfer tapes are designed to withstand extreme temperatures and environmental conditions, making them suitable for outdoor applications or environments with fluctuating temperatures.

7. **Cost-Effective**: It is a cost-effective solution for bonding needs, as it reduces the need for mechanical fasteners or liquid adhesives, which can be more expensive and time-consuming to apply.

Overall, adhesive transfer tape provides a reliable, efficient, and versatile bonding solution for a wide range of applications.

Can adhesive transfer tape be used on all surfaces?

Adhesive transfer tape is a versatile bonding solution, but it is not suitable for all surfaces. Its effectiveness depends on several factors, including the surface material, texture, and environmental conditions.

1. **Surface Material**: Adhesive transfer tape works well on smooth, non-porous surfaces like metal, glass, and certain plastics. These surfaces allow for maximum contact and adhesion. However, it may not adhere effectively to porous materials like wood or fabric, as the adhesive can seep into the pores, reducing its bonding strength.

2. **Surface Texture**: Smooth surfaces are ideal for adhesive transfer tape. Rough or uneven surfaces can limit the contact area, weakening the bond. For textured surfaces, a thicker adhesive layer or a different type of adhesive may be necessary to ensure a strong bond.

3. **Surface Cleanliness**: The surface must be clean, dry, and free of dust, oil, or other contaminants. Any residue can interfere with the adhesive's ability to bond properly. Cleaning the surface with a suitable solvent or cleaner before application is crucial.

4. **Environmental Conditions**: Temperature and humidity can affect the performance of adhesive transfer tape. Extreme temperatures can cause the adhesive to harden or soften, impacting its effectiveness. High humidity can also weaken the bond, especially on porous surfaces.

5. **Chemical Compatibility**: Some surfaces may react with the adhesive, causing degradation or discoloration. It is important to test the adhesive on a small area first to ensure compatibility.

In summary, while adhesive transfer tape is a useful tool for many applications, its suitability depends on the specific characteristics of the surface in question. Testing and surface preparation are key to achieving optimal results.

How do you remove adhesive transfer tape residue?

To remove adhesive transfer tape residue, follow these steps:

1. **Gather Materials**: You will need a clean cloth, rubbing alcohol or adhesive remover, a plastic scraper or old credit card, warm soapy water, and a hairdryer or heat gun.

2. **Heat the Residue**: Use a hairdryer or heat gun to gently warm the adhesive residue. This softens the adhesive, making it easier to remove. Be cautious not to overheat, especially on sensitive surfaces.

3. **Scrape Off Residue**: Use a plastic scraper or an old credit card to gently scrape off the softened adhesive. Avoid using metal tools to prevent scratching the surface.

4. **Apply Adhesive Remover**: Dampen a clean cloth with rubbing alcohol or a commercial adhesive remover. Test on a small, inconspicuous area first to ensure it doesn’t damage the surface.

5. **Wipe the Area**: Gently rub the cloth over the adhesive residue. The solvent will help break down the adhesive, making it easier to wipe away. Reapply as necessary.

6. **Clean the Surface**: Once the adhesive is removed, clean the area with warm soapy water to remove any remaining solvent or residue. Rinse with clean water and dry with a soft cloth.

7. **Inspect and Repeat**: Check the surface for any remaining residue. Repeat the process if necessary until the surface is clean.

8. **Polish (Optional)**: For glossy surfaces, consider polishing the area to restore its original shine.

By following these steps, you can effectively remove adhesive transfer tape residue without damaging the underlying surface.

What is the difference between adhesive transfer tape and double-sided tape?

Adhesive transfer tape and double-sided tape are both used for bonding materials, but they differ in structure and application.

Adhesive transfer tape consists of a thin layer of adhesive on a liner, without any carrier material. It is applied by pressing the adhesive side onto a surface and then removing the liner, leaving only the adhesive behind. This type of tape is ideal for applications requiring a seamless bond, as it adds minimal thickness and weight. It is often used in graphic arts, signage, and electronics where precision and a clean appearance are crucial.

Double-sided tape, on the other hand, has adhesive on both sides of a carrier material, which can be made of paper, foam, film, or other substrates. This carrier provides additional support and can add thickness, making it suitable for applications where gap-filling or cushioning is needed. Double-sided tape is commonly used in mounting, crafting, and general-purpose bonding tasks.

In summary, adhesive transfer tape offers a thinner, more seamless bond without a carrier, while double-sided tape provides additional support and thickness due to its carrier material.

How long does adhesive transfer tape last?

The longevity of adhesive transfer tape depends on several factors, including the type of adhesive used, the environmental conditions, and the surfaces to which it is applied. Generally, adhesive transfer tapes are designed for long-term bonding and can last anywhere from a few years to several decades.

1. **Type of Adhesive**: The adhesive formulation plays a crucial role in determining the lifespan. Acrylic adhesives are known for their durability and resistance to environmental factors, often lasting 5 to 10 years or more. Rubber-based adhesives may have a shorter lifespan, typically lasting 1 to 3 years, as they are more susceptible to degradation from heat and UV exposure.

2. **Environmental Conditions**: Exposure to extreme temperatures, humidity, UV light, and chemicals can affect the adhesive's longevity. In controlled indoor environments, adhesive transfer tapes can last significantly longer than in outdoor settings where they are exposed to harsh conditions.

3. **Surface Compatibility**: The surfaces to which the tape is applied also impact its durability. Proper surface preparation and compatibility ensure a stronger bond and longer lifespan. Surfaces that are clean, dry, and smooth provide optimal conditions for the adhesive to perform effectively over time.

4. **Application Method**: Correct application techniques, such as applying the right amount of pressure and ensuring full contact with the surface, can enhance the tape's longevity.

5. **Storage Conditions**: Proper storage before use, in a cool, dry place away from direct sunlight, can also extend the shelf life of adhesive transfer tapes.

In summary, while adhesive transfer tapes can last from a few years to several decades, their actual lifespan is contingent upon the adhesive type, environmental exposure, surface compatibility, application method, and storage conditions.