Anatomy of an Electrical Cable

Electrical

In today’s connected world, electrical cables are the backbone of power and communication. Whether you're powering up a home, setting up machinery in a factory, or installing high-speed internet, choosing the right cable is critical. At EYBY Marketplace, we simplify cable sourcing with a range of quality products for every application.

This guide breaks down the anatomy of an electrical cable, explains the function of each component, and outlines the types of cables to help you make informed purchasing and installation decisions.

What Is an Electrical Cable?

An electrical cable is an assembly of conductors insulated and protected by multiple layers of material to safely transmit electricity or signals. From underground power lines to indoor lighting, cables vary in size, flexibility, material, and purpose.

Why Understanding Cable Anatomy Matters

Knowing the structure of a cable helps you:

- Match it to voltage and load requirements

- Ensure safety and regulatory compliance

- Avoid signal loss or overheating

- Choose appropriate cable for the environment (indoor, outdoor, underground, or high-temperature areas)

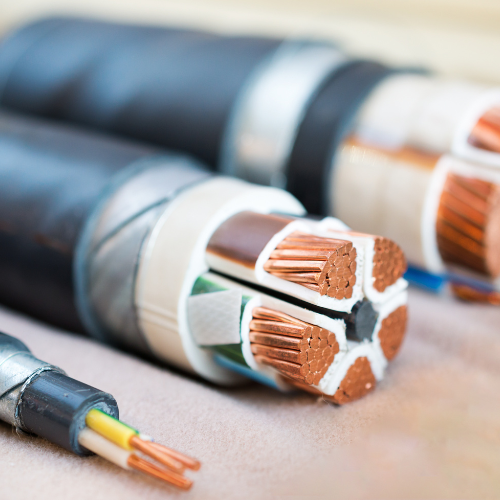

Anatomy of an Electrical Cable

Electrical cables are made up of several key layers. Each plays a role in protecting, insulating, or conducting electricity.

1. Conductor

Role of the Conductor

The conductor is the core that carries electrical current. It determines how much electricity the cable can transmit and how efficiently.

Common Conductor Materials

- Copper: Excellent conductivity, corrosion resistance, widely used.

- Aluminum: Lighter and less expensive, but lower conductivity.

Solid vs. Stranded Conductors

- Solid: One thick wire, ideal for fixed installations.

- Stranded: Many thin wires twisted together, flexible and used in portable applications.

2. Insulation

Role of Insulation

Insulation prevents electrical current from leaking and protects users from electric shock. It also keeps the cable from shorting out when conductors touch.

Common Insulation Materials

- PVC (Polyvinyl Chloride): Durable and moisture-resistant.

- XLPE (Cross-Linked Polyethylene): High thermal resistance, used in high-voltage applications.

- Rubber: Highly flexible, used in temporary or outdoor setups.

- Teflon (PTFE): Used in high-temp or chemical-heavy environments.

3. Shielding

Role of Shielding

Shielding blocks external electromagnetic interference (EMI), which can distort signals in sensitive communication or data cables.

Types of Shielding

- Foil Shielding: Thin aluminum foil; good for high-frequency protection.

- Braided Shielding: Woven copper or aluminum; more durable and flexible.

- Combination: Both foil and braid; used in audio, coaxial, and data cables.

4. Jacket

Role of the Jacket

The jacket is the cable’s outer layer, protecting it from mechanical damage, moisture, UV rays, chemicals, and abrasion.

Common Jacket Materials

- PVC: Standard for general use.

- Polyurethane: Highly flexible and tough, ideal for harsh industrial conditions.

- LSZH (Low Smoke Zero Halogen): Emits minimal smoke/toxins, used in enclosed spaces like buildings.

- Neoprene: Resists oil, sunlight, and chemicals—ideal for outdoor or industrial environments.

5. Additional Layers (Where Applicable)

Filler and Binder

Used to maintain the cable’s round shape and improve flexibility. Fillers (like plastic or cotton) prevent the layers from collapsing. Binders wrap internal components for neatness and added structure.

Armor

Armor provides mechanical protection to electrical cables, especially in installations where cables are exposed to physical stress, such as underground, in ducts, or on industrial floors.

Two main types of armor used in cables are:

- · SWA (Steel Wire Armor):

Commonly used in low-voltage power distribution for mechanical protection. It consists of galvanized steel wires and is ideal for underground systems or areas prone to impact. - · AWA (Aluminum Wire Armor):

Typically used in single-core cables because it avoids the magnetic fields produced by steel in AC systems. AWA is lightweight and corrosion-resistant, making it suitable for high-voltage, single-phase applications.

Armor helps maintain cable integrity against crushing forces, rodents, and accidental damage during installation or operation. It is especially critical in industrial, outdoor, or buried cable setups.

Common Types of Electrical Cables

1. Power Cables

Used for transmitting electricity to power appliances, machines, or buildings. These have thick insulation and strong conductors to handle high loads.

2. Control Cables

Transmit control signals in automation or machine systems. Often have shielding to prevent interference and multiple conductors for complex operations.

3. Coaxial Cables

Used for high-frequency data transmission—like in cable TV, internet, or antennas. They feature a central conductor, dielectric layer, and shield.

4. Twisted Pair Cables

Used in network and telephone wiring. Pairs of wires are twisted together to cancel out EMI. Types include:

- UTP (Unshielded Twisted Pair)

- STP (Shielded Twisted Pair)

5. Armored Cables

Designed for environments with mechanical stress—like underground power lines or factory floors. Include a metal armor layer for added protection.

Key Considerations When Selecting a Cable

1. Voltage and Current Capacity

Always choose a cable rated for your system’s electrical load to avoid overheating or failure.

2. Environmental Conditions

- Indoor Use: LSZH or standard PVC jackets

- Outdoor Use: UV-resistant, weatherproof jackets

- Harsh Environments: Use armored or polyurethane-jacketed cables

3. Signal Sensitivity

For data or communication cables, ensure proper shielding to prevent EMI and preserve data integrity.

4. Safety and Compliance

Use cables compliant with standards such as:

- IEC

- NEC

- UL-listed products

5. Future-Proofing

Plan for growth. Choose cables that can handle future upgrades (e.g., Cat6a for Ethernet or XLPE for power systems).

Common Mistakes to Avoid

- Overloading cables beyond their rated capacity

- Improper cable types for the environment (e.g., indoor cables used outdoors)

- Skipping shielding in signal-sensitive areas

- Tight bends or poor routing, which can damage internal components

Best Practices for Cable Installation and Maintenance

Installation Tips

- Use proper termination methods to avoid arcing or resistance

- Avoid sharp bends or kinks—follow minimum bend radius

- Use cable trays or conduits where necessary for protection

Maintenance Tips

- Perform regular inspections for wear or cracks in insulation

- Clean connections periodically to prevent corrosion

- Use testers to check continuity, insulation resistance, or faults

Future Trends in Electrical Cabling

As we head into 2026, we’re seeing strong demand for:

- Eco-friendly cable jackets (e.g., LSZH, recyclable materials)

- Smart cables with integrated sensors for condition monitoring

- Cables tailored for renewable energy systems, EV infrastructure, and 5G networks

Conclusion

Understanding the anatomy of an electrical cable helps ensure you select the right product for safety, durability, and long-term performance. Whether you're dealing with high-voltage power lines or sensitive data transmission, knowing your cable’s components—from conductor to jacket—makes all the difference.

At EYBY Marketplace, we’re here to support your cable sourcing with expert-backed listings and trusted suppliers. Browse our electrical category for everything from PVC house wiring to armored power cables tailored for your industry.

Frequently Asked Questions

1. What is the conductor in a cable?

It’s the metallic core (usually copper or aluminum) that transmits electricity.

2. Why is cable insulation important?

Insulation prevents short circuits, protects users, and ensures current flows properly.

3. Do I need shielding in my cables?

If you're transmitting data or working in high-EMI areas, shielding is essential to maintain signal clarity.

4. Can I use indoor cables outside?

Not recommended. Outdoor cables require jackets resistant to UV rays and weather.

5. Does EYBY offer industrial-grade cables?

Yes, we stock XLPE-insulated, armored, and heat-resistant cables for industrial and heavy-duty use.

Disclaimer: Accuracy and Reliability of Content

This blog is intended for general educational purposes only. While we strive for accuracy, readers should confirm specifications with relevant standards and consult professionals when in doubt. EYBY Marketplace does not accept liability for decisions made based on this information.